The Definitive Guide to ASTM D903, Peel or Stripping Strength of Adhesive Bonds

How to Perform a Peel or Strip Test on Adhesively-Bonded Materials

Written by Charlie Pryor

ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials. This guide is designed to introduce you to the basic elements of an ASTM D903 test and will provide an overview of the testing equipment, software, and specimens needed. However, anyone planning to conduct ASTM D903 testing should not consider this guide an adequate substitute for reading the full standard.

Challenges of ASTM D903 Testing:

- Reporting calculations in compliance with the standard

- Data rate adequate to capture peaks and troughs

- How to grip materials of various thickness

- Eliminating slippage during testing

Why Perform ASTM D903 Testing?

Testing for ASTM D903 is mainly performed for research and development purposes. Due to the standard 7 day conditioning period required by this test, it is difficult to use this method as a quality control measure. In most instances, ASTM D903 testing is used to evaluate an isolate chemical composition for adhesives that yields the best adhesive properties.

Specimens and Specimen Conditioning

To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a flexible or rigid substrate at a 180° angle at a separation rate of 152.4 mm/min, or 6in/min. Test materials must be thick enough to withstand the expected tensile pull but not greater than 3 mm (1⁄8 in.) in thickness. Wherever possible, the standard thickness of specimens is: metals, 1.6 mm (1/16 in.); plastics, 1/16 in; wood, 1/8 in; rubber compounds, 1.9 mm (0.075in.). If the flexible specimen is known to elongate when under load, it is important to use a more rigid substrate that is not expected to elongate under the same load.

All samples will need to undergo conditioning prior to testing. Standard conditioning for ASTM D903 requires the specimen to be be exposed to a monitored humidity and temperature for 7 days. For some adhesives, the conditioning period may be less if deemed unnecessary for that material. Testing is to be completed as soon as possible after the specimen has left the conditioning environment.

Test System

Due to the high data capture rate needed to record the peaks and troughs during testing, an Instron 6800 Series test frame with Bluehill Universal is recommended. 6800 Series frames have a maximum data capture rate up to 5 kHz. An ideal frame for testing adhesively bonded specimens is the 68SC-1 system. The 68SC-1 frame allows for adequate travel and has a maximum load capacity of 1 kN (225 lbs) which is appropriate for most ASTM D903 specimens. A higher capacity 6800 series test frame may be necessary if a specimen is expected to exceed this capacity. To simplify your testing, Bluehill Universal's Adhesives module comes pre-loaded with the ASTM D903 test method.

Gripping Options

Though advanced screw side action grips are the most common gripping solution for ASTM D903 testing, pneumatic side action grips are the preferred option for this type of testing. Pneumatic side action grips allow for a variable air pressure to be sent to the grips, whereas the advanced side action grips need to be manually tightened on each specimen.

Both of these gripping solutions employ a patented "quick-change" jaw face design which enables operators to easily change jaw faces to accommodate the needs of their materials. The most commonly-used jaw faces are serrated, rubber, or smooth-faced, but the use of each greatly depends on the specimens being tested. Sometimes serrated jaw faces can be too aggressive and cause premature failure at the jaw faces, whereas sometimes rubber or smooth faces can allow the specimen to slip or extrude out.

What Type of Results are Obtained from this Test?

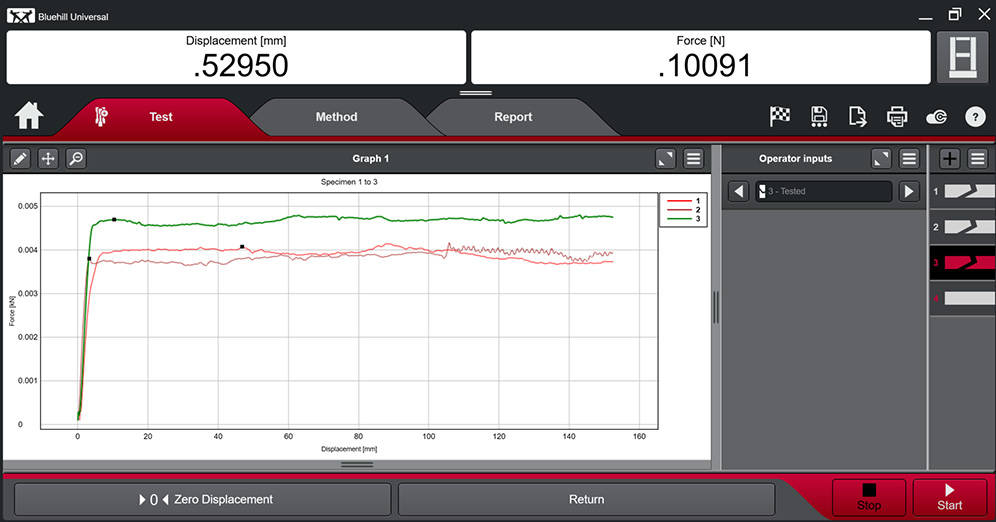

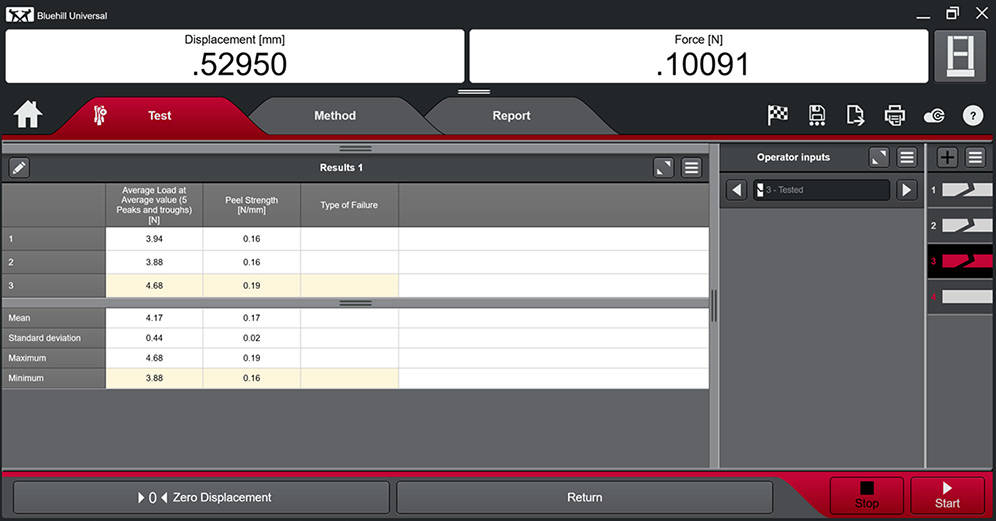

ASTM D903 measures the average load at the average value of 5 different peaks and troughs, as well as the overall peel strength. The type of failure that occurs during testing should also be recorded for analysis.

Tips for a Successful Test

It is important to use a high data capture rate when testing adhesives to ASTM D903, as a low data rate may "dull" the system and miss some of the peaks and troughs during testing, resulting in lower average strength values. A high data rate such as the 5 kHz found in Instron's 6800 series systems capture the most data possible and lead to the most accurate calculations.

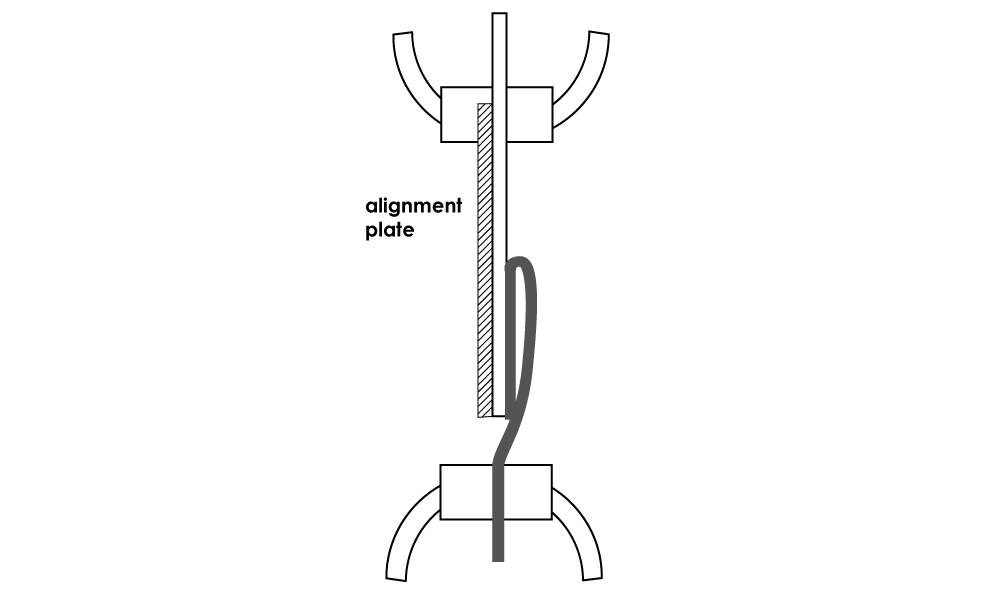

When testing a thin adherent to a thick substrate, placing the specimen in the grips can cause an offset in the load string. Using advanced screw side action grips allows for adjustability of the jaw faces and can be used to offset the adherent so there is no misalignment of the specimen.

| ASTM D903 Test Setup | |

|---|---|

Tensile Grips |

|

Alignment Plate |

|

Rigid Substrate |

|

Specimen |

|