ASTM E21: Tensile Testing on Metals at Elevated Temperature

ASTM E21 is an elevated temperature test performed in tension on metallic materials. Though this testing is used in many industries as well as academic research, elevated temperature testing is most commonly used in aerospace applications for the evaluation of mechanical properties of high strength metallic materials. Engine requirements and operating temperatures on aircraft continue to increase, as do design parameters for structural materials including fasteners. ASTM E21 meticulously outlines every step of high temperature testing; from defining the testing apparatus to thermocouple attachment. Mechanical properties such as elongation, reduction of area, tensile strength, and yield strength are recorded to estimate the material's ability to withstand applied forces.

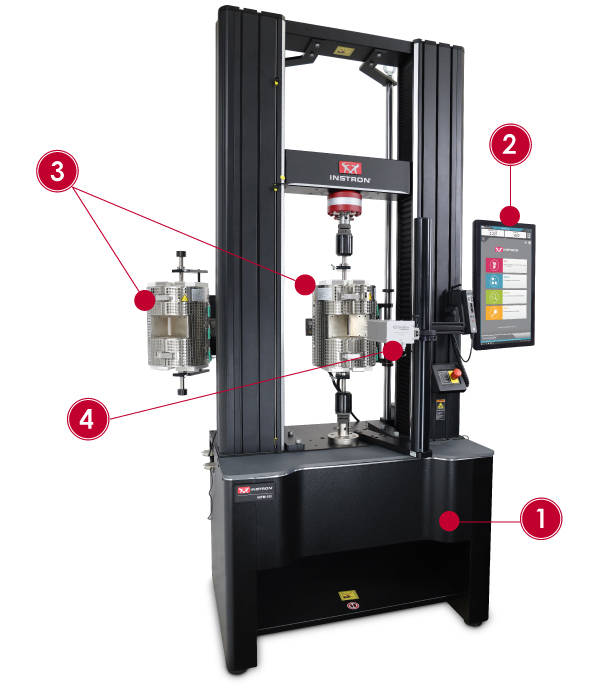

System Setup

Because ASTM E21 requires multiple transducers (extensometers and thermocouples), an Instron 6800 Series system with an expansion channel module is recommended to ensure proper data collection and synchronization. Any testing system used is required by the standard to be in accordance with ASTM E4. System and specimen preparation is crucial to E21, and every effort should be made to ensure that any force applied to the specimen remains in the axial direction. Bending strain cannot exceed 10% of axial strain on the specimen, so it is imperative to ensure the proper testing equipment is selected. For testing over 600℃ Instron recommends outfitting your 6800 Series system with a 3119-160 3 Zone Split Tube Furnace, with side entry extensometer port.

| ASTM E21 Test Setup | |

|---|---|

System Details

Inconel pull rods are attached to the specimen holders and extend into the furnace. Ceramic plates found at the top and bottom of the furnace hug the pull rods once in place, assuring that no additional insulation needs to be packed where the load string enters the furnace. Packing insulation too tightly may cause the pull rods or extensometer arms to be displaced. Pull rods sit in self-aligning holders to ensure maximum axial loading. Additionally, ASTM E21 requires monitoring of the indicated temperature on the specimen. Type K Thermocouples calibrated using Practice E220 are recommended and should follow the guidelines outlined in sections 5.3 and 9.4. From the beginning of the test through yield strength determination the indicated temperature should not exceed the following:

- Up to and including 1800F +-5 (+-3C)

- Greater than 1800f (980C) +- 10F (+-6C)

**More restrictive requirements may be necessary if indicated by the laboratory or customer.

Specimens

Specimen configurations outlined in ASTM E8/E8M are satisfactory for ASTM E21, but tighter tolerances are recommended. Geometries for specimens can be either flat or round. Flat specimens can be prepared to utilize pin-in clevis holders, while for round specimens it is customary to have threaded ends. For further guidance, review section 7 of ASTM E21.

| Specimen Holders | |

|---|---|

Strain Measurement

A Class B-2 extensometer meeting the requirements of Practice E83 is required if yield strength determination is needed. There are two primary types of extensometer that can be used for high temperature testing. The first is a cold mounted extensometer that is attached to the reduced section at ambient temperatures and is soaked with the rest of the load string before the test commences. Another option is a hot mounted extensometer, which typically sit on a rail and can be slid into the furnace for attachment once the specimen has completed its soaking period. The arms of the extensometer should be attached at the reduced section of the specimen. Extensometer attachment methods are outlined in section 9.6.

Miniature Specimens

In cases where the specimen is too small for the extensometer contact its reduced section, the separation of the crossheads or specimen holders can be used to determine strains corresponding to the 0.2% offset yield strength. This value must to be marked “approximate yield strength”. When testing a specimen with a reduced length that is less than 2 inches, a minimum of 2 thermocouples should be attached at each end of the reduced section. These thermocouples should make and maintain intimate contact with the specimen throughout the test. When testing specimens with a reduced section greater than or equal to 2 inches, a third thermocouple should be attached to the center of the specimen.

Tips and Tricks

A typical high temperature metals test can exceed one hour per specimen. To comply with the standard, a specimen must be soaked at the specified temperature until it reaches equilibrium. Once at equilibrium, the specimens must be maintained at this temperature for at least 20 minutes unless otherwise stated. If running multiple tests a day, soaking time can quickly drag out a lab’s throughput. To minimize system downtime, a universal testing system can be outfitted with a multi-furnace configuration, which allows a second specimen to soak during testing.

Terminology:

- Indicated Temperature: temperature that is indicated by the temperature measuring device using good quality pyrometric practice.

- Specified Temperature: the test temperature requested by and reported to the customer