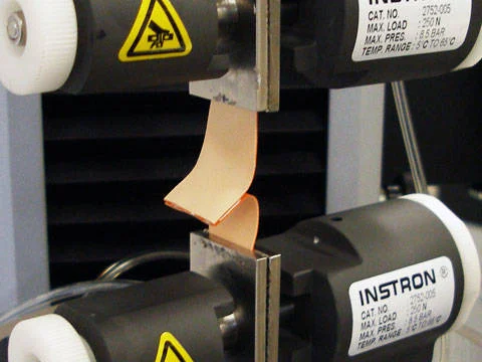

ASTM F2256 Strength Properties of Tissue Adhesives by T-Peel Testing

The biomedical industry uses tissue adhesives for applications such as bandages, secondary dressings, wound closure, and surgical sealants. The adhesive strength of these products must be clearly defined before using in a clinical setting. If the adhesive is not strong enough, the product may lead to infection or poor healing. If the adhesive is too strong, the underlying tissue may become damaged upon removal. This standard describes a test methodology for both development and characterization of these adhesives, as well as for quality control. When developing and characterizing the material properties of these adhesives in combination with soft tissue substrates, it is important to consider the environmental conditions.

The challenges of testing to this standard are:

- Testing in real world conditions

- Accurately recording adhesive strength

Instron® Solution:

- Testing in real world conditions – For this application, we recommend the BioPuls™ Submersible Pneumatic Side Action Grips and Temperature Controlled Bath. The grip's features ensure the accuracy of results, as well as allow for easy loading of the delicate, compliant, and slippery specimens with both hands. The BioPuls Bath allows for the testing of specimens at in-vivo conditions with an adjustable temperature controller.

- Accurately recording adhesive strength – Bluehill® Universal allows the user to adjust the data sampling rate of the software up to 2.5 kHz in order to capture the critical data points, and to capture all peaks and valleys throughout the test.

It is important to review ASTM F2256-05(2015) to fully understand the test setup, procedure, and results requirements.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

- Products

- 02/10/2020

- 1.93 MB

Submersible Side Action Grips and Temperature-Controlled BioBath

The submersible pneumatic side action grips and temperature controlled bath with pneumatic lifting and lowering mechanism is the ideal testing solution for a wide variety of biomedical testing applications.

- Products

- 11/09/2017

- 351.86 KB

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability

- Products

- 02/26/2017

- 3.76 MB