ASTM F384 Metallic Angled Orthopaedic Fracture Fixation Devices

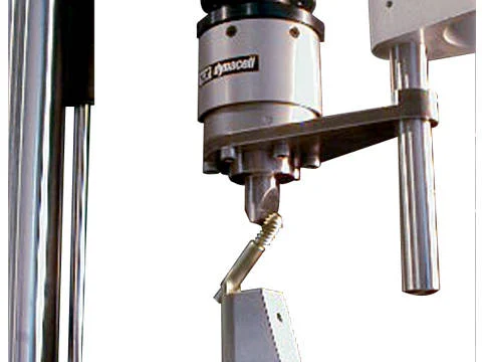

Angled orthopaedic fixation devices or hip compression screws are used to treat fractures in the metaphyseal areas of long bones. Loading creates a compression bending load at the angled portion, which must be evaluated for strength and stiffness by researchers when comparing materials and designs. Surgeons use this information to predict performance Fatigue life over a specific time or loading range. For these reasons, the test fixture must simulate compressive loads experienced by the angled portion of the plate as a result of body weight.

Testing is based on standard ASTM F384 - Standard Specifications and Test Methods for Metallic Angled Orthopedic Fracture Fixation Devices. For static testing, a ramped compression load is applied until the fixation device plastically deforms or a set deflection is reached. The objective is to determine the static bending stiffness of the plate. Four-point bending and fatigue testing, using an ElectroPuls™ Test Instrument is necessary to accurately evaluate the fixation device. The fixture is designed to work with or without a saline bath and can be adapted to suit a variety of specimen sizes and geometries.

We recommend that you review the standard to fully understand its requirements.

ElectroPuls

With more than ten years of running tests over billions of cycles, ElectroPuls systems are the established materials testing machines using patented linear motor technology. With model capacities up to 20 kN, ElectroPuls systems offer slow-speed static testing and high-frequency dynamic fatigue testing with hundreds of hertz capability. The Linear-Torsion models feature a patented actuator for bi-axial tests on materials and components.

- Products

- 06/05/2019

- 3.63 MB

ElectroPuls® E3000 Linear-Torsion All-Electric Dynamic Test Instrument

The ElectroPuls® E3000 Linear-Torsion is a state-of-the-art, all-electric test instrumentdesigned for dynamic and static testing on a wide range of materials and components. Itincludes Instron® advanced digital control electronics, bi-axial DynacellTM load cell, Consolesoftware, and the very latest in testing technology – hassle-free tuning based on specimenstiffness, electrically operated crosshead lifts, a T-slot table for flexible test set ups and a hostof other user-orientated features. Powered from a single-phase supply it requires no additionalutilities for basic machine operation (for example, pneumatic air, hydraulics, or water).

- Products

- 03/03/2017

- 306.26 KB

ElectroPuls E3000®

The ElectroPuls® E3000 Linear-Torsion is a state-of-the-art, all-electric test instrument designed for dynamic and static testing on a wide range of materials and components. It includes Instron® advanced digital control electronics, bi-axial DynacellTM load cell, Console software, and the very latest in testing technology – hassle-free tuning based on specimen stiffness, electrically operated crosshead lifts, a T-slot table for flexible test set ups and a host of other user-orientated features. Powered from a single-phase supply it requires no additional utilities for basic machine operation (for example, pneumatic air, hydraulics, or water).

- Products

- 02/06/2025

- 394.66 KB

ElectroPuls E10000®

The ElectroPuls® E10000 is a state-of-the-art, all-electric test instrument designed for dynamic and static testing on a wide range of materials and components. It includes Instron® advanced digital control electronics, bi-axial DynacellTM load cell, Console software, and the very latest in testing technology – hassle-free tuning based on specimen stiffness, electrically operated crosshead lifts, a T-slot table for flexible test set ups and a host of other user-orientated features. Powered from a single-phase supply it requires no additional utilities for basic machine operation (for example, pneumatic air, hydraulics, or water).

- Products

- 02/06/2025

- 649.8 KB

ElectroPuls® E10000 All-Electric Dynamic Test Instrument

The ElectroPuls® E10000 is a state-of-the-art, all-electric test instrument designed for dynamicand static testing on a wide range of materials and components. It includes Instron® advanceddigital control electronics, DynacellTM load cell, Console software, and the very latest in testing technology – hassle-free tuning based on specimen stiffness, electrically operated crossheadlifts, a T-slot table for flexible test set ups and a host of other user-orientated features. Powered from a single-phase supply it requires no additional utilities for basic machine operation (for example, pneumatic air, hydraulics, or water).

- Products

- 03/03/2017

- 490.57 KB