ASTM F606 Testing of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets

ASTM F606 outlines standardized testing procedures for determining the mechanical properties of externally and internally threaded fasteners, washers, direct tension indicators, and rivets. This type of testing is critical for ensuring product reliability and performance, especially in industries like automotive, industrial manufacturing, and consumer goods.

Testing Considerations

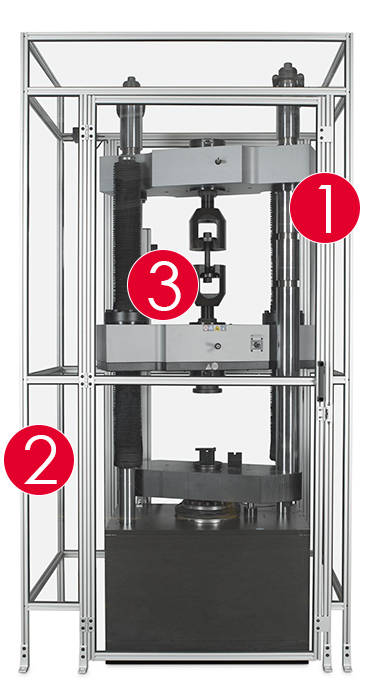

Testing per ASTM F606 generally requires applying substantial forces to metal components, making it best suited for robust, high-capacity floor model systems. We recommend using a system like the Instron 6800 Series universal testing system, paired with Bluehill Universal software, for optimal performance and precision.

For Series C and D bolts rated for loads exceeding 600 kN, a hydraulic testing system - such as Instron's HDX Series - is recommended to ensure accurate and safe testing under high-load conditions.

| ASTM F606 Test Setup | |

|---|---|

HDX Static Hydraulic Testing System |

|

W-5232 Floor-Standing Interlocked Enclosure |

|

W-5155 Fastener Holders |

|

Grips and Fixtures for Fastener Testing

For tensile testing of fasteners, Instron offers a comprehensive range of holders and inserts designed to accommodate standard fastener dimensions. These specialized accessories support a variety of test types - including proof tests, axial and wedge tensile tests, and cone stripping tests - on bolts, screws, studs, and nuts.

These accessories are compatible with most universal testing machines and include a full selection of flat, wedge, and countersunk test washers, fastener holders, short bolt adapters, holder reducing assemblies, and nut proof loading mandrels. These components enable accurate and repeatable performance for proof, tensile, and head strength testing in accordance with ASTM F606 and other relevant fastener testing standards.

For detailed specifications and part numbers, refer to Instron's Accessories Catalog, beginning on page 41.

Testing Tips and Best Practices

In accordance with ASTM F606, elongation must be recorded during fastener proof testing to verify that the fastener has not undergone permanent deformation once the load is removed. While extensometers may be used to measure elongation - depending on the test method, they are not typically used for most testing. As a result, machine stiffness becomes a critical factor in ensuring accurate results.

Instron test frames and bolt fixtures are engineered with high stiffness, enabling more consistent and reliable elongation measurements - even without the use of an extensometer.

Additionally, each Instron fastener holder is designed with a key slot for quick and precise specimen alignment. A recessed circular seat at the base of the holder ensures a snug fit for the washer, minimizing slippage and reducing setup time. This design guarantees a secure, centered seating for every test, enhancing both efficiency and repeatability.

To ensure your testing complies with the standard, we always recommend reviewing the full ASTM F606 documentation before initiating any new testing procedures.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

High Force Universal Testing Machines Brochure

Instron’s high force systems include electromechanical and high-capacity hydraulic testing systems for tension and compression applications. Force capacities range from 100 kN to 2000kN.

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability