Fatigue Testing of Finger Implants

Orthopaedic fixation devices are used during reconstructive surgery to treat fractures of bones and soft tissue injuries normally caused by trauma. Devices, such as bone plates, compression screws and femoral nails, are used to provide stability and maintain the alignment of bone fragments during the healing process. Quantification of important characteristics, such as bending strength or stiffness, can provide surgeons with insight into implant performance, while allowing researchers to compare device materials and designs. The fatigue life of the implant over a specific time period or range of maximum loading must also be determined.

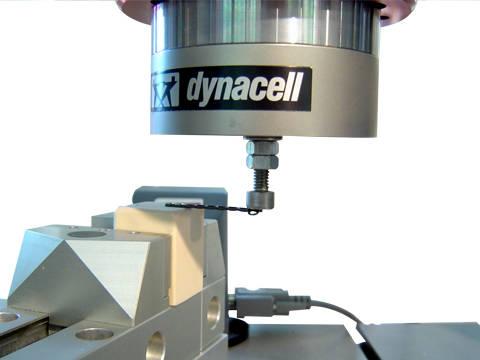

Typically following ASTM guidelines, fixtures are often unique to the objective and application of the tests and results. Features of both the ElectroPuls™ test instruments and 8870 servohydraulic testing systems, such as integral t-slot base, ability to mount the Dynacell® load cell to the moving actuator, and saline chamber accessories for in vivo simulation, allow laboratories to investigate a comprehensive range of device characteristics and performance.

For this test a small implant, commonly used to treat fracture of the phalangeal, metacarpal or carpal bones, was subject to dynamic loading to verify the fatigue life. The fixation plate was set up on both the ElectroPuls E3000 and E1000 machines. After a simple stiffness tune, a compression bending test was run at 20 Hz between 0.3 and 3 N. The test was successfully run by utilizing a lower force Dynacell load cell, a small compression platen and a clamp to fix the implant, and mounting block in position on the lower t-slot table.

ElectroPuls E3000®

The ElectroPuls® E3000 Linear-Torsion is a state-of-the-art, all-electric test instrument designed for dynamic and static testing on a wide range of materials and components. It includes Instron® advanced digital control electronics, bi-axial DynacellTM load cell, Console software, and the very latest in testing technology – hassle-free tuning based on specimen stiffness, electrically operated crosshead lifts, a T-slot table for flexible test set ups and a host of other user-orientated features. Powered from a single-phase supply it requires no additional utilities for basic machine operation (for example, pneumatic air, hydraulics, or water).

- Products

- 02/06/2025

- 394.66 KB

ElectroPuls® E1000 All-Electric Dynamic Test Instrument

The ElectroPuls® E1000 is a state-of-the-art, all-electric test instrument designed for dynamicand static testing on a wide range of materials and components. It includes Instron® advanceddigital control electronics, DynacellTM load cell, Console software, and the very latest in testingtechnology – hassle-free tuning based on specimen stiffness, electrically operated crossheadlifts, a T-slot table for flexible test set ups, and a host of other user-orientated features. Poweredfrom a single-phase supply it requires no additional utilities for basic machine operation (forexample, pneumatic air, hydraulics, or water).

- Products

- 02/06/2025

- 378.09 KB