High Strain Rate Testing

High Strain Rate Testing

Many materials exhibit different behaviors under various strain rates, i.e. they have strain rate dependent properties. Characterizing these dynamic properties across a wide range of velocities becomes very important in applications where components are exposed to high strain rates, especially on investigating the material failure and also identifying the most optimal design for weight.

High strain rate testing machines have helped industries to predict material behavior, which in turn helps the design of many components that are exposed to high strain rates during its life cycle. Whether it is in the landing gear on aircraft, the crash impact of a road vehicle or even the cord strings when a parachute is opened, all of these examples involve one or more components of a product that are subjected to high strain rate impact. These components require safety and industry standards to be met in order to compete in the industry. Therefore, a high strain rate testing machine with reliable operations and accurate data acquisition is essential in designing safe and functional products and verifying the validity of the computer simulation tools, e.g. car crash simulation.

High strain rate applications and research areas include:

- Characterization of metals, composites, and polymers from quasi-static up to strain rates of 1000/s (specimen dependent)

- Cumulative damage of aerospace components under high strain rate impact

- Crash impact of automotive vehicles

- Tensile impact on parachute cords and seatbelts

- Weight reduction of components

Why choose Instron?

Instron has provided high strain rate testing machines for 20 years and has helped to advance relevant material research in high strain rate and development of new metals, plastics, and composites. Instron continues to innovate and expand its dedicated range of high strain rate machines to accommodate a wider range of materials, applications, and more complex velocity profiles, offering more advanced data acquisition and processing techniques to ensure the data integrity of test results. Our accumulated experience in high strain rate testing will give you the edge in obtaining accurate and reliable data of materials across a wide range of strain rates, aiding you with our reliable machines in research, product design and complying with various test standards.

Instron VHS machines comply with following test standards

- High strain rate tensile: ISO 26203-2, ISO 18872

- SAE International J2749

- Puncture impact behavior: ASTM D3763, ISO 6603-2

- Peel test: ISO 11343

Safety First

Instron VHS machines are capable of moving at speeds up to 25 m/s and do so by controlled high volume, high-pressure hydraulic oil flow. With this in mind, we make operator safety our absolute priority in the design of these systems.

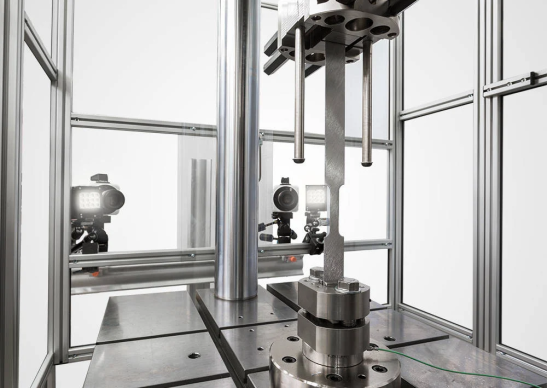

- Interlocked Safety Enclosure which restricts access to the test area during the test

- Dual Hydraulic Circuitry on all safety critical components compliant with machinery directive

- Full System CE Certification for EU shipments

Data Processing, Software, and Camera Integration

Tests can last as little as 3 - 10 ms (specimen dependent). Instron controller package accommodates by providing advanced profiling capability, high-speed data acquisition, and analysis capabilities with load transducers with a sampling rate up to 200 kHz.

- Rapid Statistical Analysis of Multiple Results Files to reduce post-processing time

- Polynomial Curve Fitting to facilitate theoretical modeling and simulation

- Third Party High-Speed DIC Camera Data Integration & Post Processing

Research a Variety of Material Properties

Instron also offers a wide variety of test dependent accessories to support different test types and service conditions. We can also include an additional environmental chamber for testing from -100°C to 250°C.

- Tensile gripping including lost motion grips and fast jaw grips to reduce impact rebound

- Compression fixture with side load protection

- Puncture Probes and 3-point bend fixture with suitable force-pin transducers

High Strain Rate VHS Systems High Speed Testing up to 25 m/s Many materials exhibit different behaviors under various strain rates, i.e. they have strain rate dependent properties. Characterizing these dynamic properties across a wide range of velocities becomes very important in applications where components are exposed to high strain…High Strain Rate VHS Systems