JEDEC JESD22B113

Written by Fulin Liu and Charlie Pryor

THE CHALLENGEBoard Level mechanical tests are an essential quality control test within the microelectronics packaging industry. They provide testing data to support IC components' performance against interconnect failures during shipment and in end-use products where cyclic stresses and shock from impact are experienced.

OUR SOLUTION

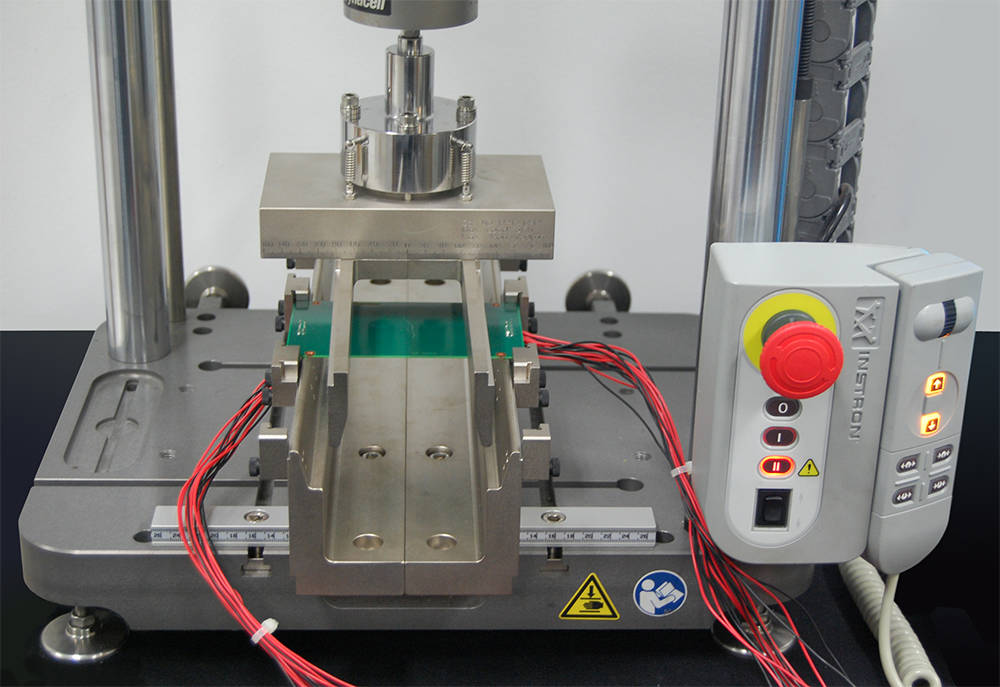

The standard recommends a specimen design similar in size and layout to a drop Impact test. It specifies the spans and the cyclic amplitude, frequency, and waveform for performing this test. Interconnection failure is determined based on resistance daisy chains, typically five times the initial resistance or 1000ohms, whichever is higher. The challenge of the JEDEC JESD22B113 test that an operator must have the test system continuously generate the flexural loading based on a specified cyclic waveform on the printed wiring board (PWB) via the 4-point bend to long-time fatigue – up to 200,000 cycles at 1-3Hz frequency without lateral specimen shifting.

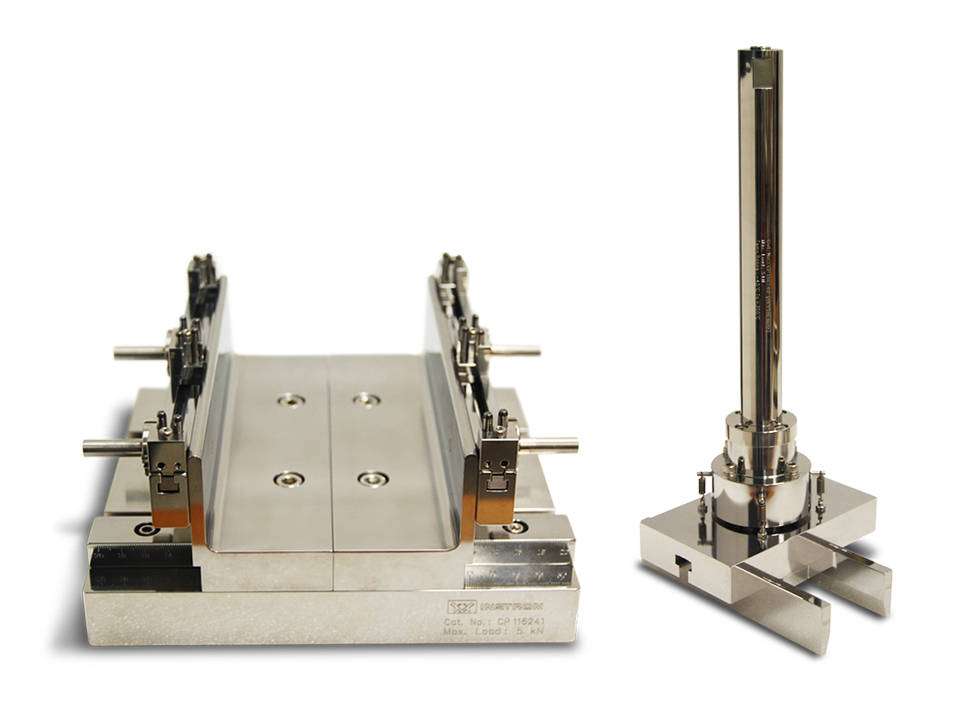

The JEDEC B113 test fixtures CP111414 and CP118691 are specially designed in accordance with the JEDEC JESD22B113 method for performing long-time cyclic 4-point flexural fatigue tests. Easy setup of removable specimen stops is to prevent undesired drifting of the specimen during the cyclic test. As a displacement-controlled test, the fixtures are designed to allow for up to 4 PWB specimens to be tested simultaneously in one setup, which saves time.

JEDEC B113 Fixture

RELATED CONTENT