Servo valves

Challenge

To provide the performance envelope required at each test axis, the actuator and servo-valve must be correctly sized and set up. Different tests require different performance characteristics such as a dynamic force, a displacement, a test frequency or a specific velocity. According to the requirement, the servo-valve type and size plays a critical role in getting good control accuracy at the performance level identified. The Servo-valve is therefore a key component in the design of any test system.

Solution

Instron offers a full range of servo-valves from 5 liters to 2400 liters/mins which can be fitted to the Hydropuls linear and rotary actuators to meet a wide range of test applications.

Up to 60 liters/min, we offer a variety of mechanical and electrical feedback 2 stage servo-valves, manufactured according to our specification. Manifolds are available to install up to four of these valves onto a single actuator providing high response performance up to 250litres/min per actuator.

From 250 to 2400 liters/min, Instron has developed a range of 3 stage valves. The characteristics of these valves have been optimized to provide the best possible performance in test applications when combined with the Hydropuls actuators. Special versions of these valves are also available for applications which require specific control characteristics.

For applications such as Damper testing where both high velocities and low speed precision control are necessary, it’s possible to install both 3 stage and 2 stage valves onto one control channel using a switching manifold to select the valve required.

2-stage servo valve

In the first stage an electrical input signal of low power is converted into a differential pressure signal. The differential pressure causes displacement of a spool which controls the effective power in the form of hydraulic energy flow. Bearing in mind the requirements of servohydraulic tests facilities, servovalves should have a linear frequency response in the upper frequency range.

It is possible to increase this power potential by connecting four servovalves in parallel. Where high energy flows are to be controlled Schenck prefer to use three-stage servovalves and have developed units capable of producing an effective power output of 2.2 MW.

3-stage servo valve

A second spool with a large cross sectional area is attached to a small 2-stage servovalve. The position of the second spool determines at this stage the supply and return flow resistance for the oil which acts on the piston areas of a Hydropuls® actuator. The spool position is measured by means of a displacement transducer and controlled by a PD controller and the pre-control servovalve. Using this electrical feedback principle, the 3-stage servovalve features almost the frequency characteristics of its pre-control valve.

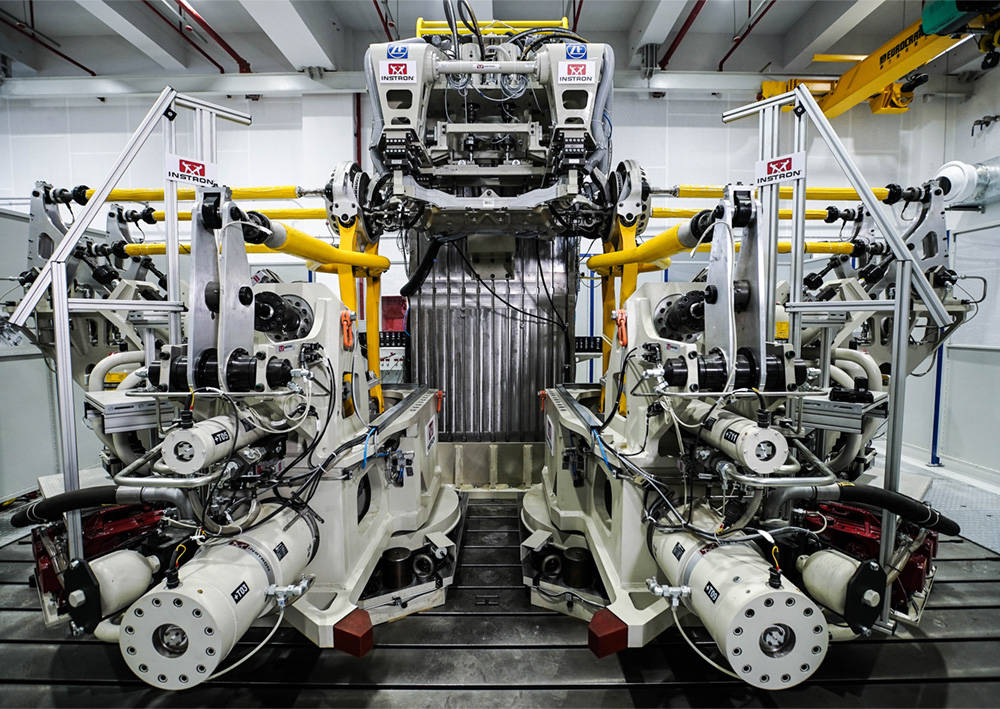

Axle Test System

Axle test rigs are used to reproduce different loads applied to the axle elements when a vehicle is traveling over a variety of road surfaces. Instron can provide models for testing of car, van, truck and bus axles with 6 degree-of-freedom.

Saber maisComponent Test Systems

Instrons component testing systems are characterized by the highest quality and reliability, ensuring the highest productivity in daily use.

Saber maisMulti-Axis Shaking Table (MAST)

Multi-axis simulation (MAST) tables are designed for testing of a variety of different specimens in six degrees of freedom. These include components and subassemblies exposed to vibratory loads during vehicle operation; from seats, dashboards and interior equipment components to engine mounts, and cooling modules.

Saber maisRoad Simulator

HYDROPULS® road simulators are a versatile and cost efficient solution for testing load inputs through the tires. They are used to perform durability tests, as well as acoustic and vibration analyses in testing and development (BSR, NVH) on complete vehicles, subsystems and power train assemblies.

Saber maisFull Vehicle Test System

Instron offers comprehensive solutions with and without vehicle restraint, with long- or short-stroke introduction of lateral forces as well as the optional environmental simulation with regard to temperature humidity and sun loading.

Saber maisDynamic Torsion Test System

The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed.

Saber maisShock Absorber Test Systems

Instron's MSP test system is the ideal tool for reliable, fast and realistic tuning of vehicle chassis designs and development of shock absorber systems.

Saber mais