Composite Laminates Tensile Testing

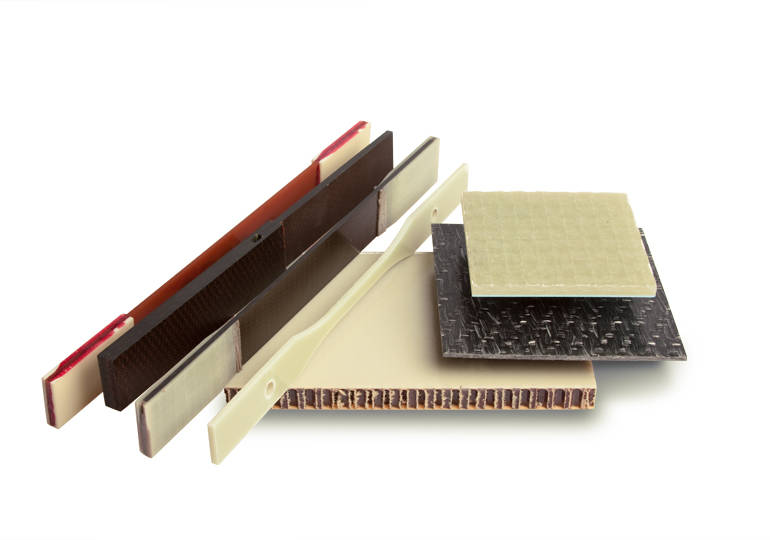

A wide range of new materials are being used to decrease the weight of vehicles and reduce emissions. Of these new materials continuous carbon fiber polymer composites offer great potential for producing lightweight structures, however, there are many barriers to their widespread adoption. Currently, the cost and process times of composites parts are significantly higher than those of traditional metal parts and they require new recycling techniques. Progress is being made with the development of lower cost carbon fibers and thermoplastic matrix materials that offer faster manufacturing processes and facilitate recycling.