THE CHALLENGE

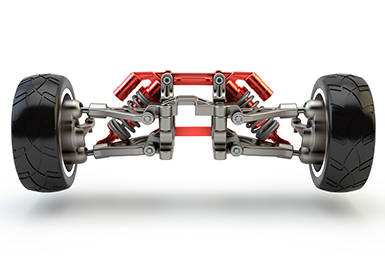

Time to market pressure increases the demand to test at the sub-system level, and axle development is one area where designs can be validated prior to having the prototype vehicle available. Complete axles, including sub frames, steering systems, drive shafts, stabilizers, brakes, and active components need to be tested as a system using road loads, strains, accelerations, and vehicle control signals to accurately simulate track conditions and validate service life. Electric vehicle development can add to the challenge by introducing drive motors into the axle design, and the need to simulate characteristics, such as drive and brake torques, reaction torques, motor mass, and control systems.