COMPOSITES TESTING

Trusted by global leaders in aerospace, automotive, energy and R&D, Instron delivers advanced solutions for composite materials testing.

Over the last 75+ years, Instron has installed over 75,000 systems at top-tier manufacturers, research institutes and universities worldwide. From the earliest days of the composites industry, we have been at the forefront - developing test systems, contributing to ASTM and ISO standards, and enabling breakthrough materials innovation.

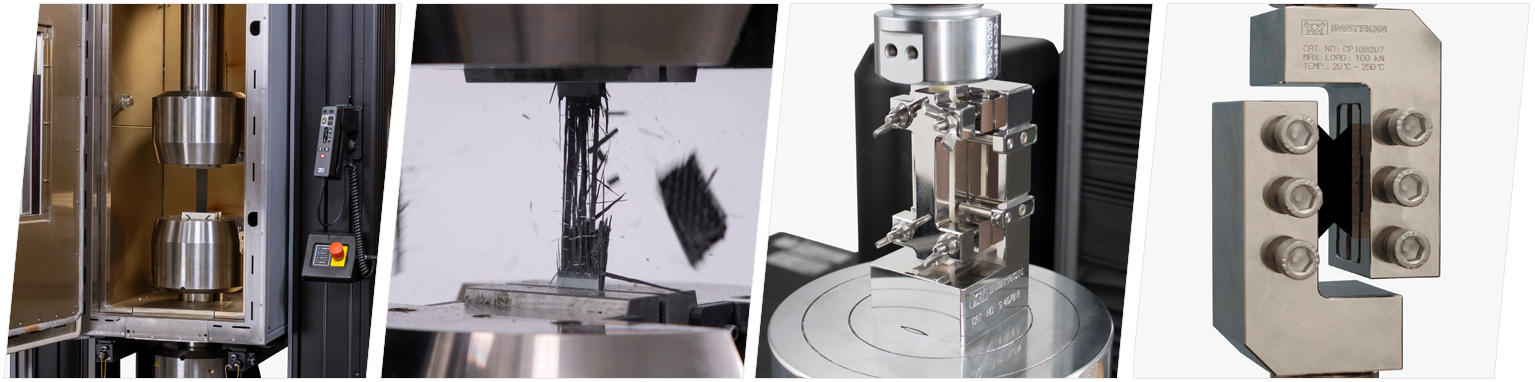

Instron testing systems are purpose-built for the unique challenges of composite materials, featuring robust frames, advanced ingress protection, and enhanced durability to withstand the shock and debris associated with extreme specimen failures. Our broad portfolio of grips and fixtures is engineered to meet stringent alignment requirements, while enabling tensile and compression testing without removing the primary grips - preserving alignment. Configurations integrate seamlessly with environmental chambers for non-ambient testing and support advanced extensometry for the most accurate strain measurement.

KEY CONSIDERATIONS

For Selecting a Composites Testing System

When selecting a testing system for composite materials, it's critical to evaluate the following performance and usability factors:

Composites testing demands robust, precision-aligned systems that maintain performance under the most demanding applications.

- Frame Integrity:Instron systems feature pre-loaded bearings and thick crossheads to minimize compliance and energy storage during testing.

- Shock Load Protection: Low-stretch drive belts and robust structural components help prevent damage to the system from sudden load releases.

- Debris Management: Integrated ingress protection shields electronics from composite dust and debris, ensuring long-term reliability.

Meeting Nadcap alignment requirements is critical for aerospace and other regulated industries. Instron electromechanical systems are designed to minimize bending and compliance. Many models meet Nadcap standards without an alignment cell, while others can be configured with alignment tools and software for more complex setups. Our Service Team can perform alignment verification to support your next audit.

Learn more about the AlignPro fixture and software.

Accurate force measurement across a wide range is essential for multi-purpose testing. Understanding the usable range and accuracy of your load cell helps reduce the need for frequent changes, improving efficiency and preserving calibrations. Instron load cells offer up to ±0.5% of reading accuracy down to 1/1000th of capacity.

Learn more about Instron load cells.

Temperature control impacts throughput and test reliability. Instron environmental chambers are engineered for rapid heat-up and recovery times, enabling efficient high and low temperature testing.

Learn more about environmental chambers.

Composite testing often involves varied specimen types and standards. Precision alignment throughout the load string is essential to meet ASTM, ISO, EN, and Nadcap requirements. Instron offers a wide range of grips and fixtures purpose-built for composite applications.

Explore Instron’s composites testing grips and fixtures.

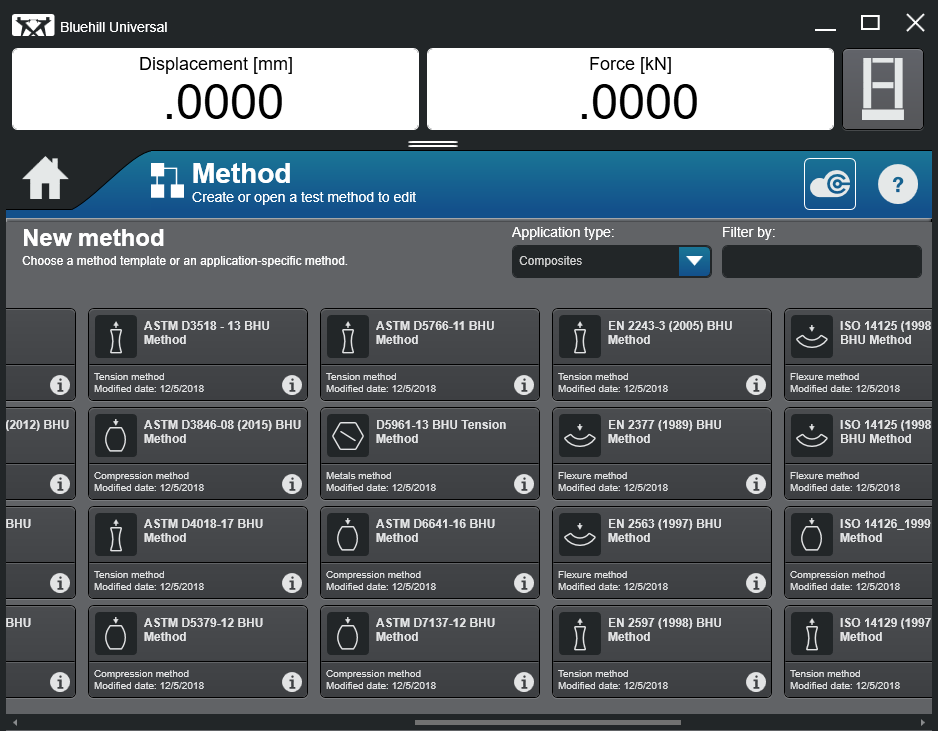

Software should support both new and experienced operators. Bluehill® Universal includes a comprehensive library of composite test methods, making it easy to adapt templated methods to your specific needs.

Learn more about Bluehill Universal software.

Reliable strain data is critical, especially during explosive material failures. Instron offers both contacting and non-contacting extensometers designed to withstand extreme events while delivering precise data.

Learn more about Instron’s extensometers

GRIPS AND FIXTURES

Engineered for Composites Testing

In addition to offering a comprehensive suite of Instron composite test fixtures, Instron systems are fully compatible with all Wyoming Test Fixtures. This ensures your lab can confidently perform a wide range of ASTM and ISO standard tests using Instron equipment.

ALIGNMENT REQUIREMENTS

Meet Strict Application Standards

Accurate alignment is essential when testing composite materials, particularly to meet the rigorous standards of aerospace applications. Instron testing systems are precision manufactured with high axial and lateral stiffness. They feature large diameter ball screws with guidance columns, and are compatible with adjustable AlignPRO™ alignment fixtures to ensure optimal alignment throughout the test process.

This high level of precision supports Nadcap compliance, helping laboratories achieve consistent, repeatable results in demanding environments.

ENVIRONMENTAL CHAMBERS

Evaluate Composites Performance at High and Low Temperatures

Instron’s environmental chambers are engineered to support precise mechanical testing of composite materials across a broad temperature range—from -150°C to +600°C—with full control via Bluehill® Universal software.

Each chamber features multi-paned viewing windows, allowing clear observation of the test process and enabling the use of non-contacting extensometers for accurate strain measurement.

Designed for efficiency, the chambers offer rapid heating and cooling cycles, helping operators maximize throughput and reduce downtime between tests.

STRAIN MEASUREMENT

Reliable Measurement for Composites Failure Conditions

Precise strain measurement is critical when testing composite materials, especially for safety critical applications. Instron manufactures and calibrates contacting and non-contacting extensometers specifically designed for composite testing, ensuring high accuracy and repeatability.

Instron systems also integrate seamlessly with strain gauges, giving you flexibility in measurement techniques to meet the demands of your testing standards

BUILT-IN TEST METHODS

Faster Setup. Consistent Results.

The Bluehill Universal Composite Module includes a wide range of pre-configured composite testing standards, allowing you to get started quickly without the need to build methods from scratch. It also ensures consistent and repeatable testing across different systems and laboratories, helping you meet ASTM, ISO, and EN requirements with confidence.

RECOMMENDED TESTING SYSTEMS

For Composites Materials and Components

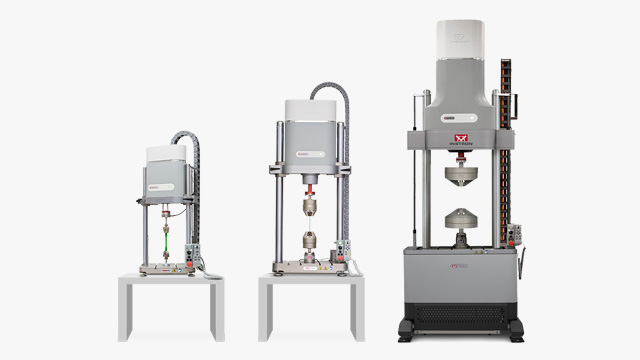

Universal Testing Systems

Instron universal testing machines are ideal for performing static mechanical tests such as tensile, compression, bend, and shear on composite materials and components. These systems support a wide range of ASTM, ISO, and other industry standards, ensuring reliable and repeatable results across labs.

Impact Testing Systems

Instron’s drop towers and pendulum systems are designed to evaluate the impact resistance of composite materials. From basic un-instrumented setups to fully instrumented systems with ultra-high-speed data acquisition, these solutions help qualify materials for demanding applications like aerospace and automotive.

Dynamic & Fatigue Testing Systems

Instron’s ElectroPuls® and servohydraulic systems deliver dynamic testing capabilities for composites, with force ranges from 1 kN to 5,000 kN. These systems are ideal for fatigue, fracture, and cyclic loading tests, helping engineers understand long-term performance and failure modes under real-world conditions.

FREQUENTLY ASKED QUESTIONS

For Composites Applications

ADDITIONAL RESOURCES

Composites Testing Standards

ASTM D3039 Tensile Properties of Polymer Matrix Composite Materials

ASTM D3410 Measuring the Compressive Strength of Polymer Matrix Composites

ASTM D3846 In-Plane Shear Strength of Reinforced Plastics

ASTM D4018 Standard Test Methods for Properties of Continuous Filament Carbon and Graphite Fiber Tows

ASTM D5766 Open-Hole Tensile Strength of Polymer Matrix Composite Laminates

ASTM D5961 Bearing Response of Polymer Matrix Composite Laminates

ASTM D6484 Open Hole Compressive Strength of Polymer Matrix Composite Laminates

ASTM D6641 Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture

ASTM D7137 Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

Brochures

On-Demand Webinars

Intro to Composites Testing Standards and Methods

Achieving More Consistent Data in Composites Testing

Strain Measurement Solutions for Composite Testing

Introduction to Mechanical Testing for Composites

Reducing Variability in Composites Testing

Tips and Tricks for Testing Composites

A Guide to Composites Fracture Toughness and Sandwich Construction Testing

Articles

As materials evolve, testing insights deepen

Composite testing challenges, Part 1: Introduction to mechanical testing of composites

Composite testing challenges, Part 2: Strain measurement for the mechanical testing of composites

Composite testing challenges, Part 3: Testing systems