Biomedical Systems and Accessories

Whether your application involves syringes, Luer locks, auto-injectors, pen injectors, sutures, prosthetics, implants, medical packaging, or PPE, Instron offers a range of fixtures and accessories for testing to industry standards. To learn more about the latest testing applications for drug delivery devices and containers, medical consumables and packaging, cardiovascular and interventional devices, biomaterials, orthopedic implants, and dental devices, visit our Biomedical Industry page.

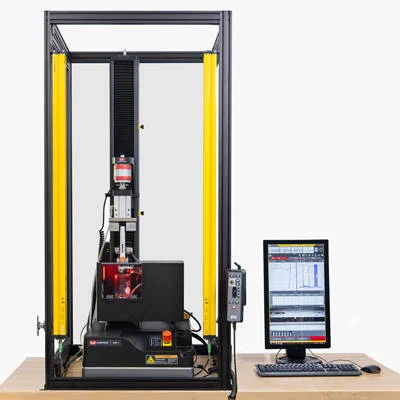

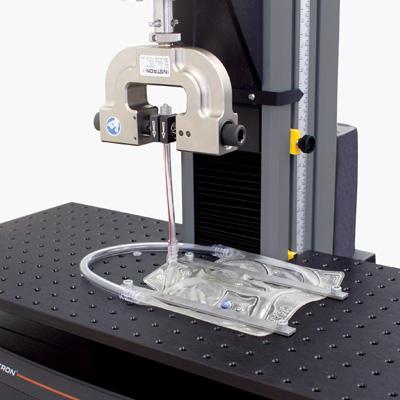

Instron’s ISO 80369 system is built on our advanced 6800 Series universal testing machines with biaxial capabilities, delivering exceptional performance and flexibility to support a wide range of medical device testing.

By consolidating mechanical and pressurized leakage performance tests into a single machine, it enhances efficiency, reduces evaluation time, and minimizes device usage. Featuring modular configurations for syringes, IV hubs, and connectors, this system ensures precise alignment and adaptability for diverse device geometry. Maximize your testing capabilities with the Instron ISO 80369 system, engineered for both standard and custom device testing.

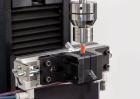

Our range of syringe fixtures are designed to investigate the forces necessary to evaluate the performance of syringes and syringe/needle combinations. The fixtures used in conjunction with the test system can determine the forces required to operate the device – specifically the break loose and glide force.

The CP131100 universal syringe fixture is designed to accommodate a wide range of common syringe sizes between 1 ml and 50 ml. The adjustable gripping mechanism makes it easy for operators to adjust for multiple syringe sizes, perfect for test labs. The 2870-001 syringe fixture is simple in design, using specific inserts to support the syringe flange during testing.

We also offer a separate syringe test fixture, catalog no. 2870-003, specifically designed to meet the test requirements of ISO 7886-1 Annex G for sterile, single-use hypodermic syringes.

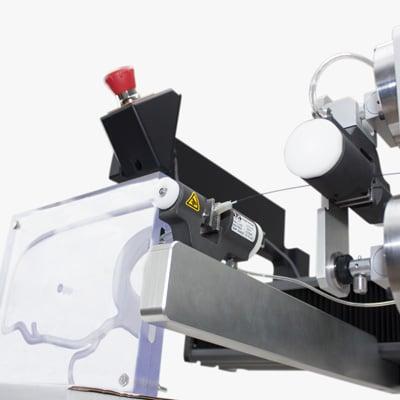

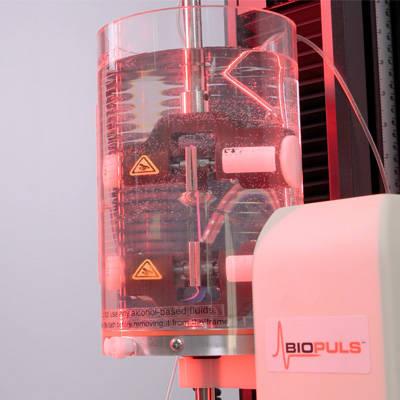

Instron’s Automated Carousel Testing System utilizes an innovative, adaptable design for testing of medical vials, cartridges, and pre-filled syringes. The small footprint allows it to be put on standard lab benches adding automation to even the smallest labs. It is designed with easy wipe-down surfaces and stainless steel covers for biomedical environments. Commonly configured to automate testing of residual seal force (RSF) and compression testing.