Tensile Impact Test Method with Drop Weight Impact Tester

Tensile Impact Test Method with Drop Weight Impact Tester

Tensile Impact Test at High Strain Rates

How to Perform Tensile Impact Test

A tensile impact test measures the toughness of polymers using an impact tester for plastic according to the ISO 8256 standard. Polymers that are too flexible or thin for a Charpy or Izod impact test generally require an uniaxial tensile impact test with a relative high strain rate.

When evaluating the elastic response of a material, quasi-static tensile testers are used to determine most of the mechanical properties. However, a wide variety of polymeric materials are sensitive to strain and require an impact tester for plastic that can run a tensile impact strength test at both quasi-static and high velocities.

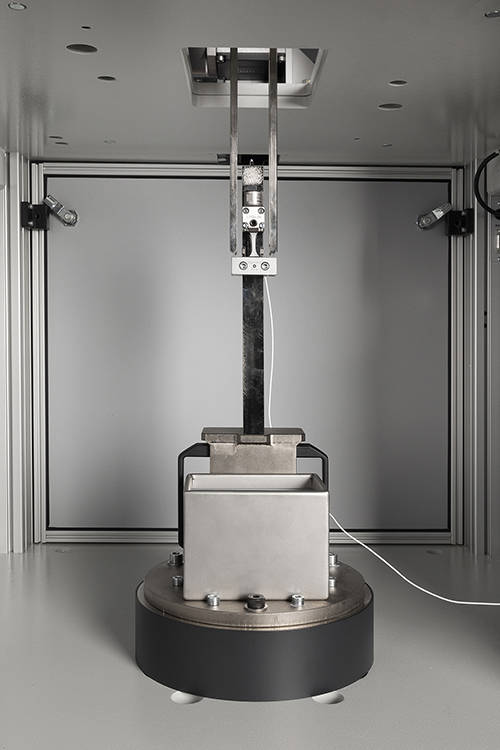

The Instron impact test apparatus can reach a wide range of impact velocities from relatively low (0.7 m/s) to very high (22m/s). Thanks to variable impact masses, the test velocity remains as constant as possible during the elongation of the specimen. Instron’s impact test apparatus covers impact energies between 1 and 1,800 J.

The specific setup for the tensile impact test involves:

- A dedicated tensile-impact striker

- A tensile-impact vice equipped with a piezoelectric load cell (up to 2.2 kN) or a strain-gauge sensor (up to 15 kN), a screw grip with V-shaped jaw faces and a calibrated free tensile grip (crosshead)

- A Data Acquisition System with a piezoelectric or strain-gauge channel

With the combined use of a drop weigh impact testing machine equipped with Bluehill® Impact Software, tensile impact accessories, High Speed Camera and Digital Image Correlation software, it is possible to evaluate the longitudinal strain of the specimen when impacted under tensile-Impact conditions.

Instron recommends Photron High Speed Camera Fastcam Mini Series.