Pendulum Impact Testing Machine

Pendulum Impact

Testing Machine

Pendulum Impact Testing Machine for Plastics and Composite Materials

The Instron CEAST 9050 impact pendulum enables to determine the impact resilience of plastics and composites, easily and safely. The Instron CEAST 9050 impact pendulum tests comply with all the main ISO and ASTM impact testing methods, ranging from 0.5 - 50J and including Charpy, Izod and Tensile Impact.

Charpy Pendulum Impact Test and Other Testing Methods

Impact Test

Efficient Testing

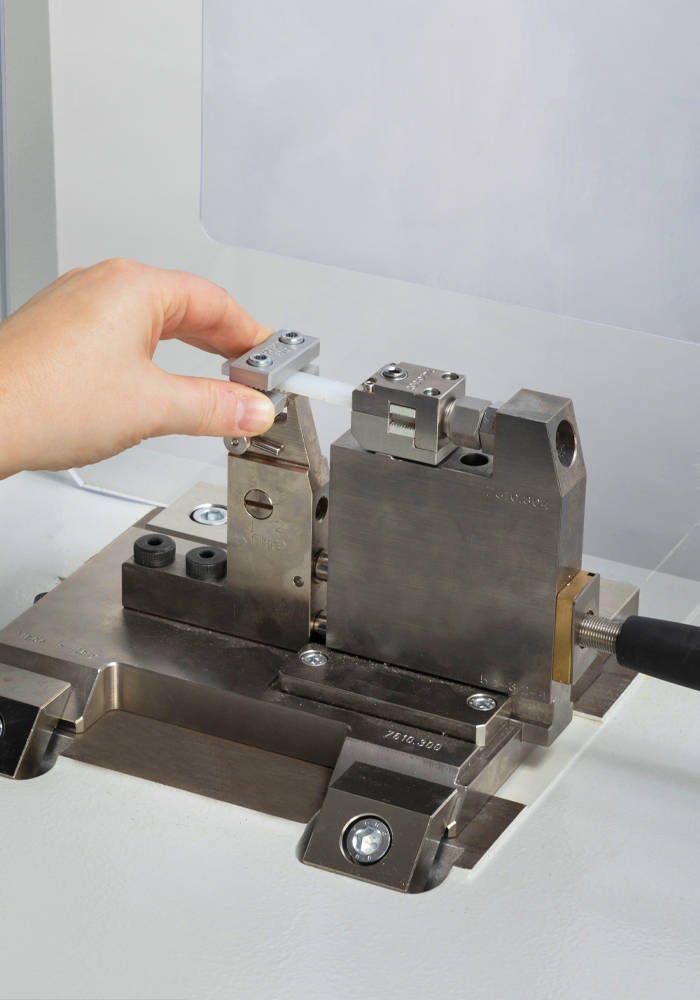

The ergonomic set-up of the hammers and specimen supports enable the user to work safely and efficiently.

Pendulum Impact Energy

Switching from high (50J) to low (0,5J) energy hammers and from Charpy to Izod configurations is quick and easy.

Integrated Control Panel

The integrated touch panel PC enables you to take control of your testing and maximize lab efficiency with an extensive set of test parameters stored for prompt use.

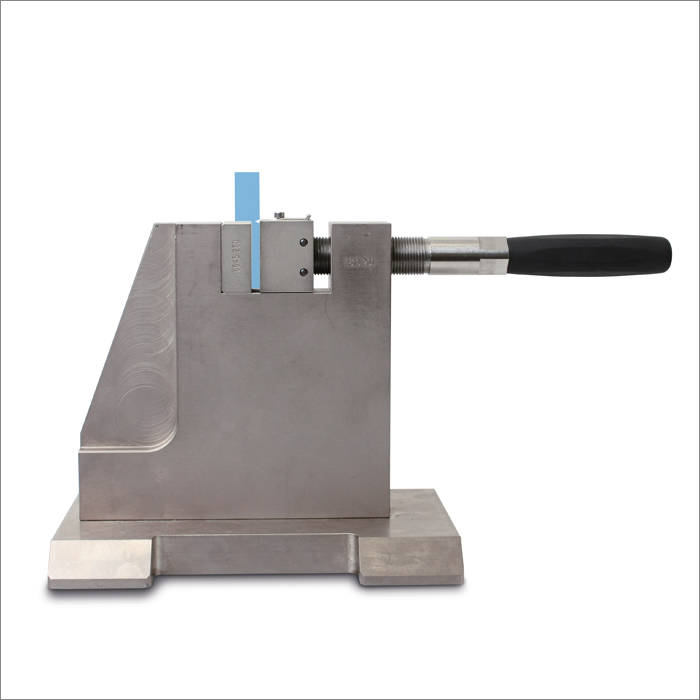

Double Braking Mechanism

The hammer disk brake on the manual pendulum assures high torque, low effort and smooth operations, along with double braking surface and convenient position.

Advanced Performances

The touch panel PC displays critical information, such as percentage of the absorbed energy, so that each test is run according to the testing standards.

The “one piece” patented hammer structure, specifically designed to reduce the energy wasted in vibration, ensures incomparable rigidity and superior accuracy.

With the optional software, add value to results and export data post-test, from a professional report with graphs and tables to customized text files.

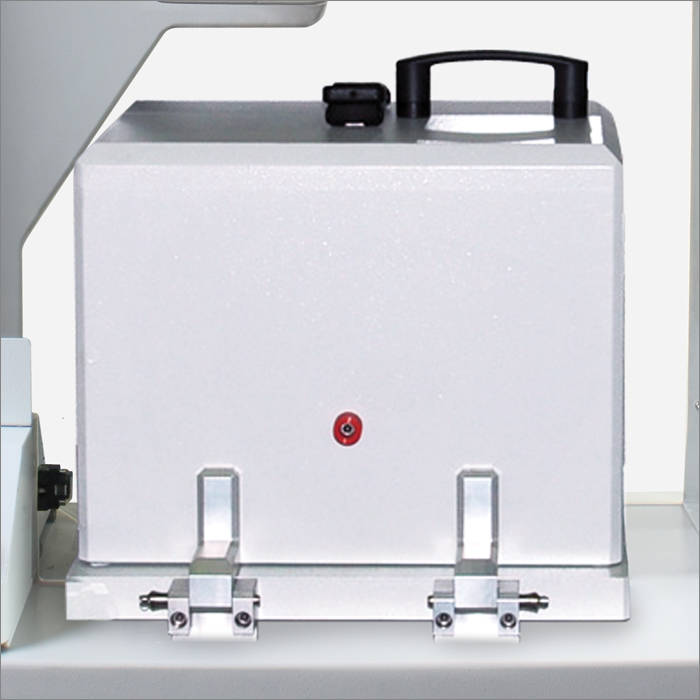

The optional thermal conditioning chamber, positioned to enclose the specimen vice, guarantees quick time to impact when testing at low temperatures.

Stiff Frame for Better Reliability

The advanced electronics automatically recognizes the mounted hammer and retrieves all its relevant data from the internal database, eliminating the risk of manual errors.

When performing pendulum impact tests, accurate energy values can only be achieved with a system made of a robust monolithic structure and a precise non-contacting magnetic encoder able to ensure zero friction.

Safety guards prevent unwanted access to the test area ensuring maximum protection.

All instrumented hammers are wire free: any downtime due to hammer connection set-up and damages to the wire are eliminated.

Pendulum Impact Testing Machine

Extras

Specification Table

| CEAST 9050 Manual | CEAST 9050 Motorized | ||

| Hammer Energy Range |

J

ft-lb |

0.5 – 50 0.37 – 36.9 |

0.5 – 50 0.37 – 36.9 |

| Hammer Release | - | Manual

(Pneumatic Optional)

|

Pneumatic |

| Hammer Braking | - | Manual | Pneumatic |

| Hammer Recovery | - | Manual | Motorized |

| Hammer Identification | - | Automatic | Automatic |

| Electrical Supply | - | 100 – 240 V 50 – 60 Hz |

100 – 240 V 50 – 60 Hz |

| Compressed Air Supply |

bar

psi |

5 72.5 |

5.5 79.8 |

| Machine Dimensions (w x d x h) |

mm

in |

1035 x 430 x 880/1190 40.8 x 16.9 x 34.6/46.9 |

1035 x 510 x 1190 40.8 x 20.1 x 46.9 |

| Machine Weight |

kg

lbs |

220 (330 with 50 J Plate) 485 (725 with 50 J Plate) |

270 (380 with 50 J Plate) 595 (838 with 50 J Plate) |

| Safety Guards | - | Standard (Full Enclosure Optional) |

Full Enclosure |