ASTM F2516 Tension Testing of Superelastic Nickel-Titanium (Nitinol) Materials

ASTM F2516 specifies the standard test method for evaluating the tensile properties of superelastic nickel-titanium (Nitinol) materials. Unlike conventional materials, Nitinol exhibits unique behavior - its structure changes in response to temperature changes and when applying mechanical stress.

This results in distinct stress-strain profiles during loading and unloading. To capture this behavior properly, ASTM F2516 measures both upper and lower plateau strength, rather than a single yield strength.

The test involves stretching the material in tension to 6% strain, unloading it to a value less than 7MPa, and then pulling it to failure - providing a comprehensive view of its mechanical performance.

WHAT IS NITINOL USED FOR?

Nitinol’s unique properties make it invaluable in the biomedical field. It’s commonly used to manufacture stents, dental archwires, catheter guidewires, fracture fixation devices, and biopsy forceps.

One of Nitinol’s most remarkable features is its shape memory: when formed at a specific temperature, it “remembers” that shape. If cooled, it can be reshaped, but once reheated to its original temperature, it automatically returns to its initial form. This behavior is especially useful in stent design. Stents made from Nitinol can be compacted for easy delivery through blood vessels and then expand to their intended cylindrical shape once they reach body temperature.

Nitinol is also widely used in orthodontics. Braces made with Nitinol wire gradually shift teeth into alignment using the heat from the mouth to activate the wire’s memory effect. Unlike traditional braces, Nitinol wires maintain consistent pressure and require fewer adjustments, improving patient comfort and treatment efficiency.

TEST SETUP

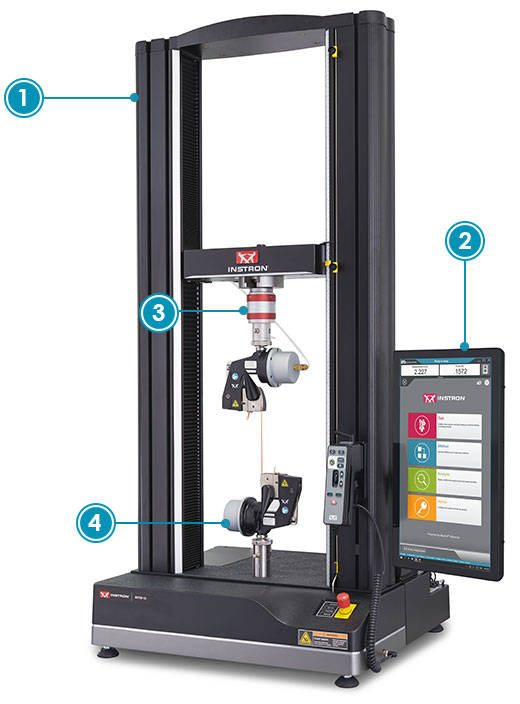

ASTM F2516 is typically conducted using dual-column test frames, such as the Instron 6800 Series universal testing systems, which offer the precision and control required for superelastic materials. A 5 kN load cell is generally suitable for most Nitinol specimens.

A pre-configured ASTM F2516 test method is available within Bluehill Universal's Biomedical Applications Module and requires the TestProfiler module to execute the full test sequence.

| ASTM F2516 Test Setup | |

|---|---|

| 1) | 6800 Series Universal Testing System |

| 2) | Bluehill Universal Software |

| 3) | 2580 Series Load Cell |

| 4) | 2714-005 Pneumatic Cord and Yarn Grips |

GRIPS AND FIXTURES

Grip selection for ASTM F2516 testing depends on the specimen diameter. Pneumatic cord and yarn grips are ideal for smaller diameters, offering secure and gentle clamping. For larger specimens, pneumatic side action grips with serrated faces provide a consistent clamping force throughout the test to prevent slippage.

STRAIN MEASUREMENT

Strain measurement in ASTM F2516 testing depends on the diameter of the Nitinol wire. For specimens 0.2 mm or smaller, strain can be accurately measured using crosshead displacement. For wires larger than 0.2 mm, a Class C extensometer is required. Popular choices include the Instron AutoX750 automatic contacting extensometer and the AVE3 advanced video extensometer, as traditional clip-on devices may introduce errors due to their weight and interaction with delicate specimens.

Additionally, specimen diameter and gauge length determine the appropriate test speed. To simplify setup, the Expression Builder in Bluehill Universal can be used to automatically adjust test speed based on specimen parameters to comply with the standard.

Temperature control is also critical. Testing must be conducted at a temperature at least 5°C above the material’s austenitic finish transformation temperature to ensure the Nitinol is fully in its austenitic phase. Testing below this threshold may result in partial phase transformation, compromising the accuracy of the results.