ASTM E8 Tension Testing of Metallic Materials

How to Perform a Tension Strength Test on Metals According to ASTM E8 / E8M

ASTM E8 / E8M is one of the most widely utilized standards for determining the tensile properties of metallic materials. Alongside ASTM A370, it serves as a foundational method in materials testing across industries.

Originally introduced in 1924 under the designation ASTM E8-24T, this standard holds the distinction of being the oldest actively used metals testing standard. Over the decades, ASTM E8 has undergone numerous revisions to reflect advancements in testing practices and industry needs.

A major update occurred in March 2008, when ASTM E8 (imperial units) and ASTM E8M (metric units) were merged into a single unified standard: ASTM E8 / E8M. This consolidation simplified compliance and improved clarity for global testing.

This guide provides a comprehensive introduction to ASTM E8 / E8M tensile testing, including:

- Overview of the tensile testing process

- Required materials testing equipment

- Software and strain measurement accessories

- Standardized tensile specimens

While this guide is meant to provide a helpful overview, it is not a substitute for reading the full ASTM E8 / E8M standard. Those conducting testing to this standard should refer directly to the official documentation to ensure full compliance.

Key Tensile Properties Measured by ASTM E8 / E8M

ASTM E8 / E8M is used to evaluate the tensile properties of metallic materials at ambient temperatures ranging from 10°C to 38°C (50°F to 100°F). This standard is essential for assessing the mechanical performance of metals in various forms, including sheet, plate, wire, and bar.

While ASTM E8 / E8M covers a wide range of tensile characteristics, the following are the most commonly measured properties:

- Yield Strength - The stress at which a material undergoes permanent deformation.

- Yield Point Elongation - The transitional phase where the material shifts from elastic to plastic deformation.

- Tensile Strength - The maximum force or stress a material can withstand before failure.

- Reduction of Area - A measure of ductility, calculated by the decrease in cross-sectional area after fracture.

These properties are critical for material selection, quality control, and engineering design, making ASTM E8 / E8M a cornerstone in metallurgical testing and mechanical analysis.

CHOOSING THE RIGHT TESTING SYSTEM

Because ASTM E8 / E8M tensile testing is performed on a wide range of metallic materials, from thin sheet metals to thick steel plates, the required testing force can vary significantly. To accommodate this diversity, the Instron 6800 Series universal testing systems offer a versatile lineup of universal testing machines with load capacities ranging from 10 kN for lightweight materials (i.e. sheet metal) to 600 kN for heavy-duty applications like steel plate testing.

The 6800 Series load frames are engineered for precision and durability, featuring:

- Pre-loaded bearings

- Precision ball screws

- Robust crosshead and base beam

- Low-stretch drive belts

These advanced mechanical components contribute to high-accuracy results and minimal energy storage, which is especially critical when testing high-strength materials such as aerospace propulsion system alloys, structural steels for suspension bridges, and metals used in automotive chassis.

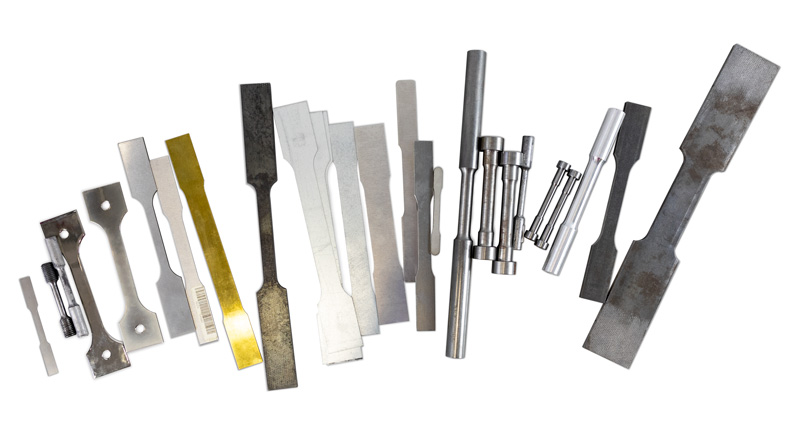

SPECIMEN TYPES AND STANDARD DIMENSIONS

ASTM E8 / E8M accommodates a wide variety of specimen types to suit different forms of metallic materials. The standard outlines precise geometries and dimensions for each specimen category, ensuring consistent and reliable tensile testing results.

Common specimen types include:

- Flat and round bars

- Tubes and sheets

- Pin-loaded specimens

- Powder metallurgy products

Among these, the most frequently used specimen types are:

- Dogbone-shaped flat specimens featuring a width of 12.5 mm (0.5 in) and a gauge length of 50 mm (2 in)

- Buttonhead round specimens with common diameters of 6.35 -12.7 mm (0.25 - 0.50 in) and gauge lengths of 25.4 - 50.8 mm (1 - 2 in)

By defining standardized specimen geometries, ASTM E8 / E8M ensures repeatable testing procedures across laboratories and industries, making it a cornerstone in mechanical testing of metals.

TESTING CONTROL METHODS

Like many widely used metals testing standards, ASTM E8 / E8M outlines three distinct types of test control methods to regulate test speed:

- Method A - Stress Rate Control

- Method B - Strain Rate Control

- Method C - Crosshead Speed Control

These control methods are critical for ensuring consistent and repeatable tensile test results, especially when comparing materials or validating mechanical properties. This video breaks down: what is strain rate control, why is it important, how can you implement it, as well as some challenges that may occur.

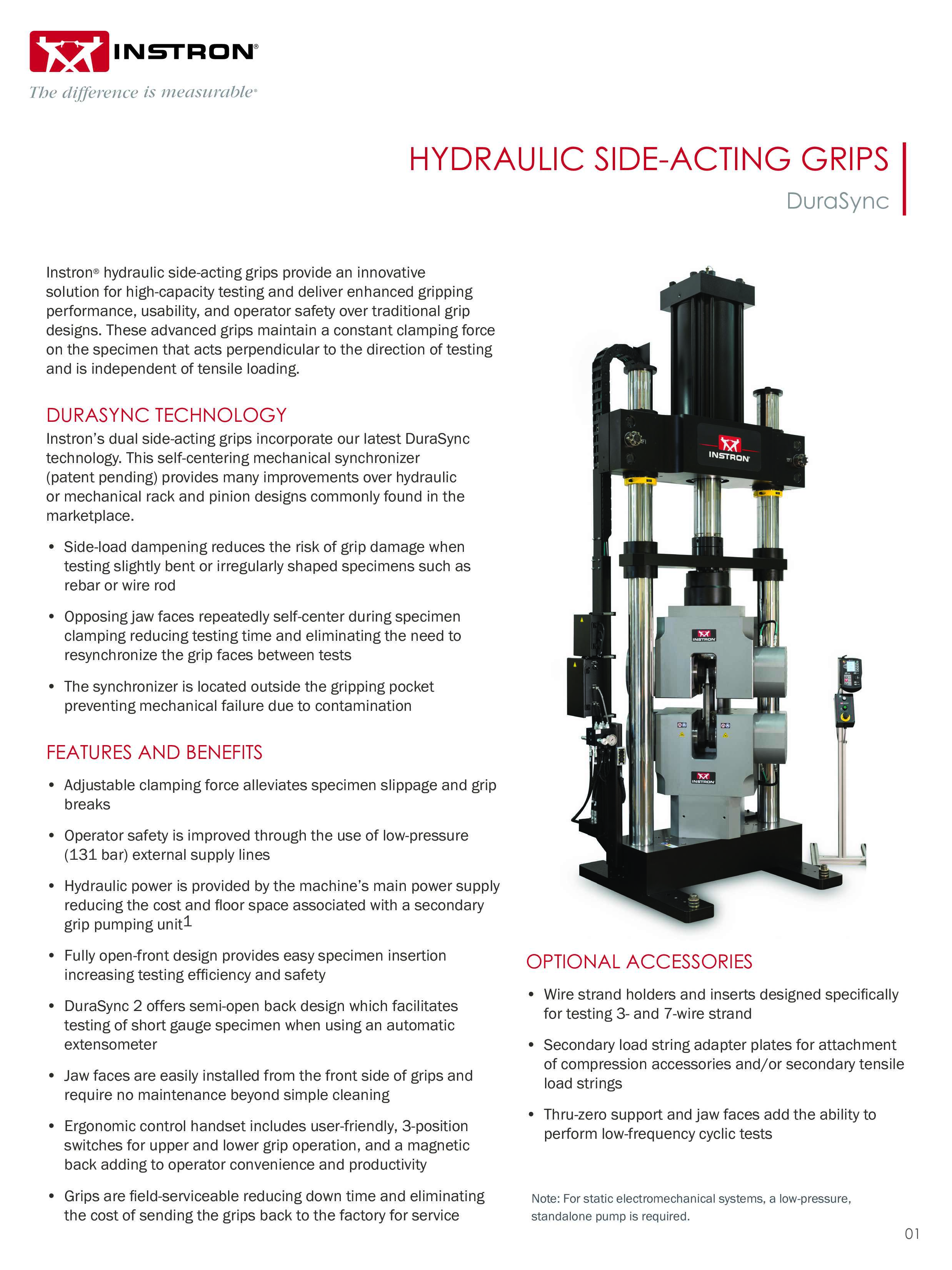

TENSILE GRIP OPTIONS

ASTM E8 / E8M tensile testing supports a variety of gripping technologies, including wedge grips, side-acting grips, hydraulic grips, and pneumatic grips. These grips are essential for securing the specimen during testing and can be broadly classified into two categories based on how they apply clamping force:

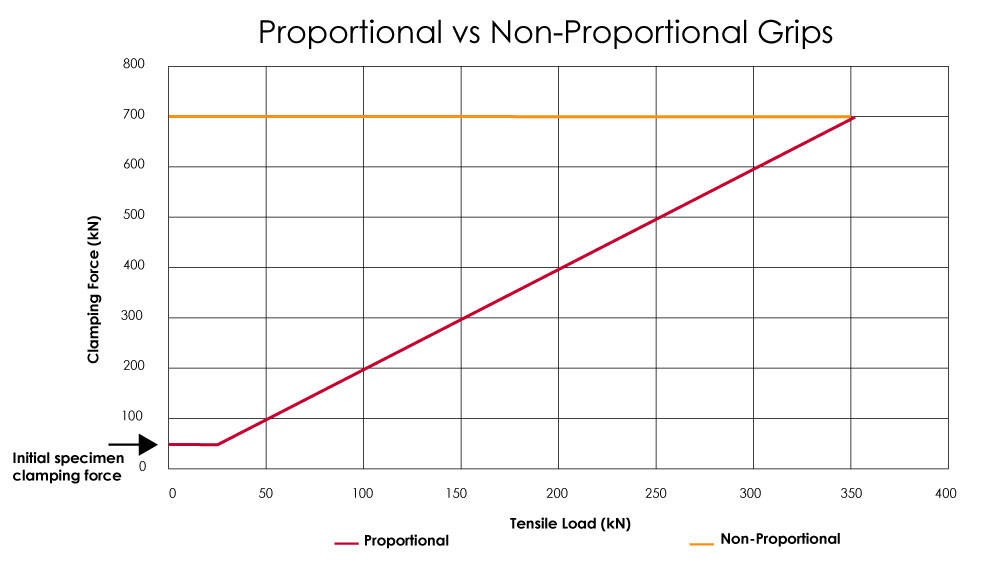

Proportional grips increase clamping force in direct relation to the tensile load applied during the test. As the load rises, so does the grip pressure, ensuring secure specimen retention throughout the testing process.

- Wedge grips are the most common type of proportional grip. Available in manual, pneumatic, and hydraulic configurations, they are versatile and suitable for a wide range of testing applications.

- The wedge design naturally enhances grip strength: as the specimen is pulled, it slides deeper into the narrowing wedge, increasing pressure and preventing slippage.

Non-proportional grips maintain a constant clamping force that is independent of the tensile load. This force is typically generated by an external power source, such as a high-pressure hydraulic system (often rated at 210 bar / 3000 psi or higher).

- Common examples include side-acting grips and fatigue-rated hydraulic wedge grips.

- A key advantage of many non-proportional grips is the adjustable clamping force, which allows for greater flexibility in testing different materials and specimen types.

Choosing the right grip type is critical for achieving accurate and repeatable results in ASTM E8 / E8M tensile testing. The decision depends on factors such as specimen geometry, material properties, and test requirements.

SPECIMEN PROTECTION

During tensile test setup, inserting a specimen into the grips can unintentionally introduce compressive forces. These forces occur when the gripping pressure slightly displaces material, which is then pushed back into the specimen body, creating a load against the load cell. This can lead to premature deformation and inaccurate test results.

To mitigate this issue, proportional grips are recommended. Unlike non-proportional grips, proportional grips apply a lesser force during setup, reducing unwanted compressive loads.

For enhanced protection, Instron 6800 Series universal testing systems feature Specimen Protection technology. This intelligent system automatically adjusts the crosshead position during setup to eliminate compressive forces, regardless of the grip type used. This ensures more accurate data collection and helps preserve the integrity of the specimen before testing begins.

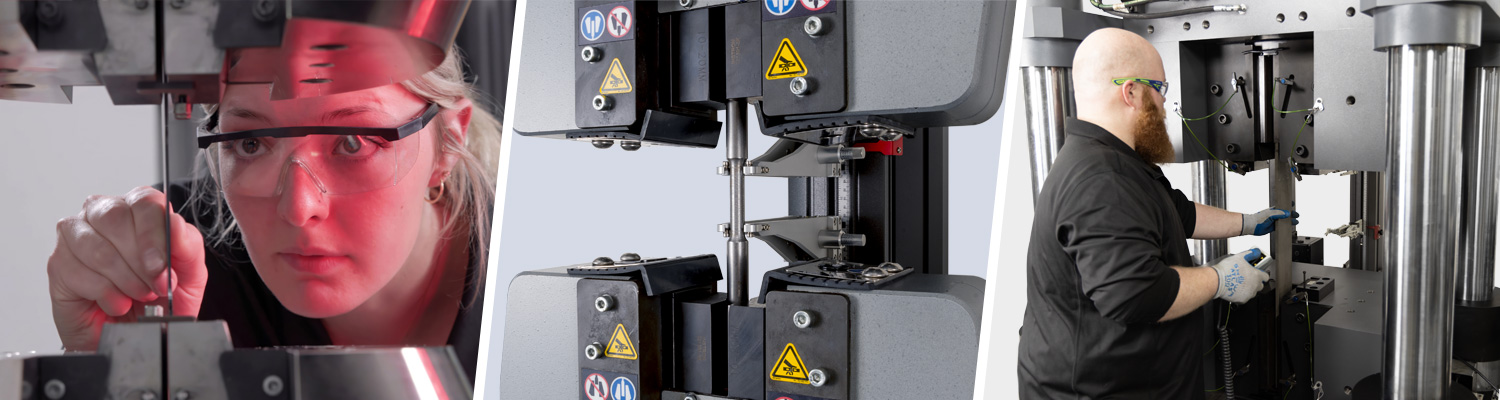

Extensometers for Measuring Tensile Strength

The type of extensometer needed for ASTM E8 / E8M varies depending on strain value. Most metals testing standards require a high-accuracy device to determine material properties at lower strain values - including modulus and yield strength. While a slightly lower-accuracy device is acceptable for high strain values - including uniform elongation and total elongation.

To ensure precision, ASTM E8 / E8M references ASTM E83 for extensometer classification:

- For strain values below 5%, a Class B2 or better extensometer is required.

- For strain values above 5%, a Class C or better extensometer is required.

There are three primary types of extensometers commonly used in ASTM E8 / E8M testing:

- Clip-On Extensometers - Clip-on devices, such as Instron's 2630 Series, are the most widely used due to their high accuracy and cost-effectiveness. It's critical that the design be robust enough to withstand high-throughput testing environments and be able to absorb the shock from specimen breakage during high-capacity tests.

- Automatic Contacting Extensometers - Devices like the Instron AutoX750 offer automated specimen attachment, consistent placement, and multi-gauge length adaptability - reducing operator variability and improving repeatability. When paired with Bluehill® Universal software, the AutoX750 can automatically detach before specimen failure, minimizing wear on knife edges.

- Non-Contacting Extensometers - Instron's AVE3 Advanced Video Extensometer provides optical strain measurement without physically touching the specimen. This is especially beneficial for thin or fragile materials, where clip-on devices may alter results or cause premature failure. Non-contacting systems also eliminate the risk of damage during high-capacity testing, ensuring long-term operational integrity and measurement accuracy.

Calculations and Results

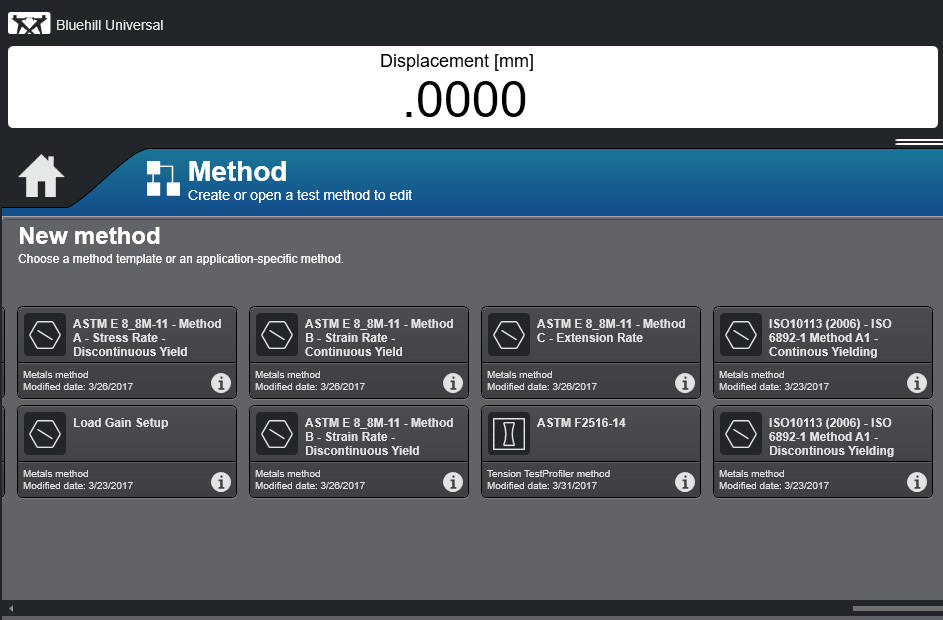

Bluehill Universal software streamlines tensile testing by offering preconfigured calculations for ASTM E8 / E8M, eliminating the need for manual setup. This allows users to quickly begin testing with confidence in the accuracy and compliance of their results.

For those who prefer a customized approach, Bluehill Universal also supports manual configuration of calculations, enabling users to build tailored methods that meet the specific requirements of ASTM E8 / E8M and other standards.

The Metals Methods Package further enhances flexibility by providing pre-built testing methods for a wide range of international and industry standards, including:

| Spring Templates ASTM A370 ASTM A615 ASTM C39 ASTM C78 |

ASTM E8 / E8M ASTM E21 ASTM E345 ASTM E517 ASTM E646 |

ASTM F606 ISO 10113 ISO 10275 ISO 898 ISO 6892-1 |

Improving Throughput

Many laboratories conducting ASTM E8 / E8M tensile tests handle a high volume of specimens on a regular basis. As a result, improving testing throughput is essential for maximizing efficiency and reducing operational costs.

Fortunately, there are several strategies to streamline the testing process:

- Software enhancements: Minor adjustments in testing software, such as automating repetitive tasks and streamlining inputs, can significantly reduce setup time and operator workload. Check out our YouTube channel for software tips and best practices.

- Advanced grips and extensometers: Using equipment designed for quick setup and high repeatability minimizes errors and reduces the need for retests.

- Full automation: For labs seeking maximum efficiency, fully automated testing systems can run for hours without operator intervention, making them ideal for high-throughput environments.

By implementing these solutions, labs can achieve faster turnaround times, more consistent results, and improved productivity in ASTM E8 / E8M compliant testing.