Las pastillas suelen tener un recubrimiento para facilitar su deglución, liberar de manera gradual la medicación, o estampar la identificación o la marca. Estos recubrimientos también pueden ayudar a alargar la vida del producto en condiciones ambientales negativas, tales como la exposición a la luz, temperatura, humedad y carga mecánica. En particular, en el proceso de fabricación y embalaje, los revestimientos de los comprimidos estás sujetos a impactos que pueden causar daños.

Los ensayos de impacto pueden proporcionar datos valiosos para los fabricantes con la finalidad de conocer el rendimiento de los materiales de revestimiento o el desarrollo de materiales nuevos. El fabricante puede implementar también un control de calidad que permita validar el proceso en curso utilizando los datos obtenidos por un ensayo de impacto.

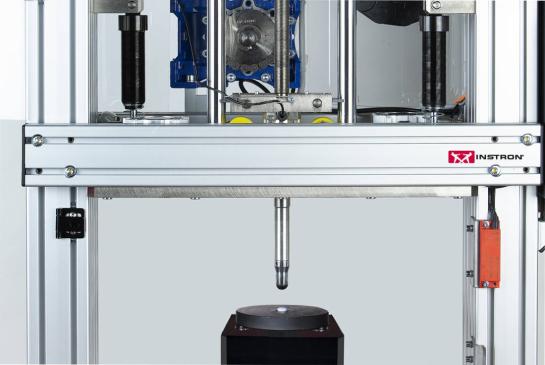

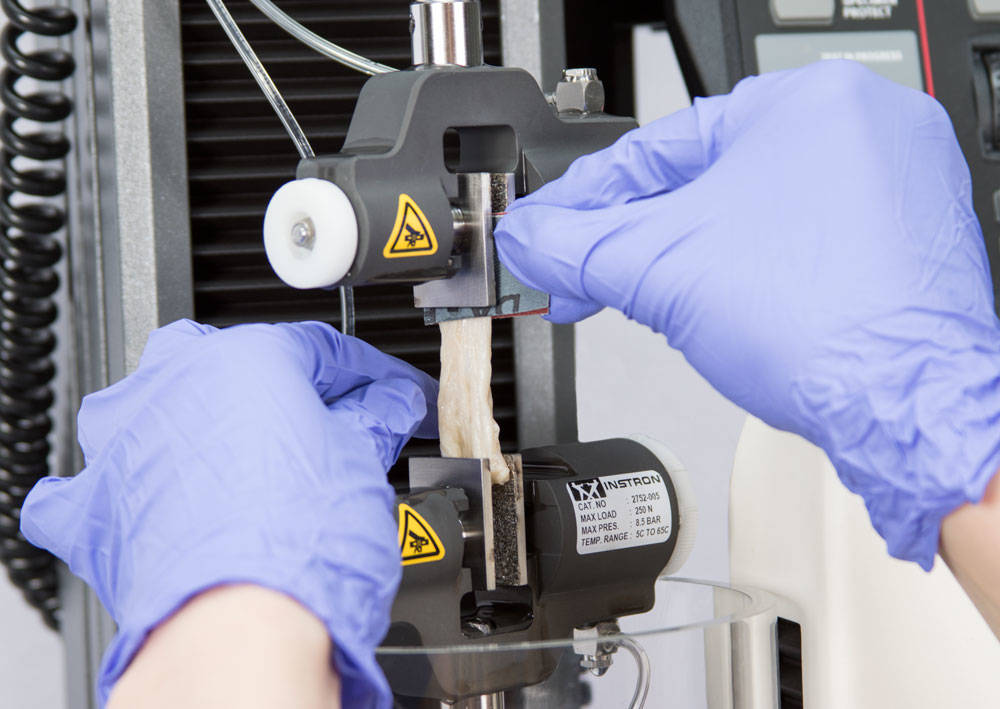

Para realizar estos ensayos una torre de caída INSTRON 9440, equipada con un sensor piezoeléctrico de baja carga Tup (0,45 kN o 4,5 kN), inserto semiesférico o plano de ½ pulgada y el software Bluehill Impact son ideales para la prueba de píldoras y tabletas farmacéuticas. Para la fijación, recomendamos utilizar una placa de metal rígida, plana, que se puede asegurar fácilmente al área de la mesa.

Esta solución de ensayo de impacto es muy adecuada para determinar las características de resistencia al impacto de comprimidos farmacéuticos, así como la consistencia del lote o los puntos de daño incipiente. Estas características pueden estar, a su vez, relacionadas con el material de recubrimiento utilizado en el producto. Al comprender como el recubrimiento puede fortalecer o debilitar las píldoras se podrán realizar mejoras en el producto.