Synthetic membranes are commonly used in the biomedical field. These polymeric membranes, designed to mimic the natural filtration systems in human bodies, are being researched and developed for use in drug delivery systems, medical devices, and artificial bio-organs.

For example, synthetic membranes are used in hemodialysis, which is a method of removing waste products from the body when the kidneys fail. Blood from the patient is passed through a semi-permeable membrane that is immersed in dialysis solution and waste products such as urea in the blood diffuse across the membrane into the dialysis solution.

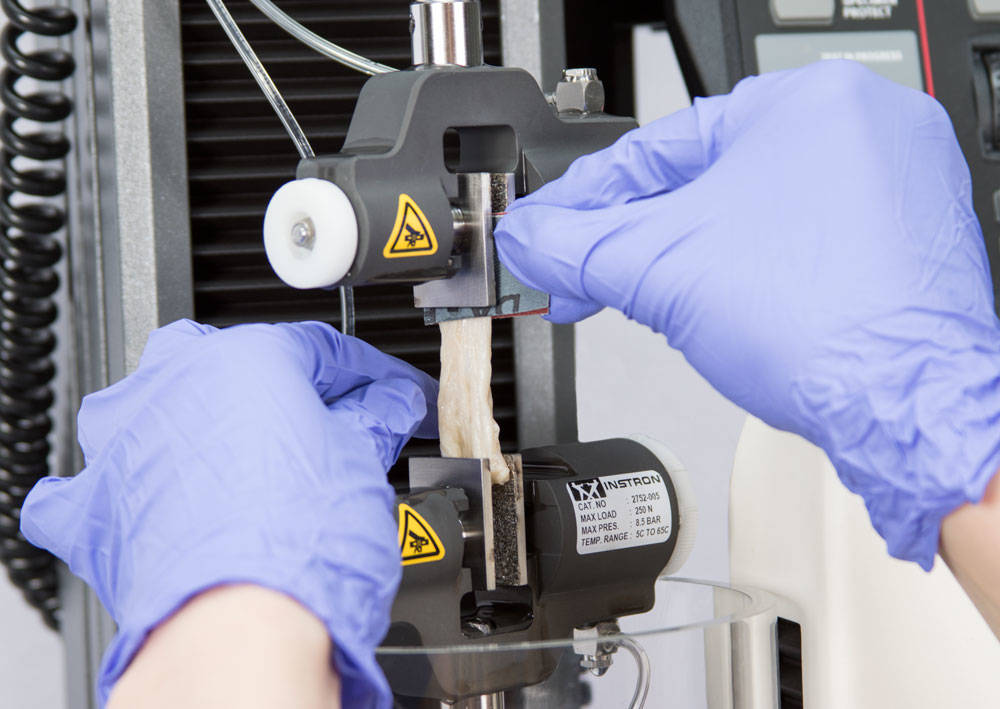

Often these synthetic membranes are moist and slippery, and consquently, tensile testing can be challenging. Similar to testing soft tissues, the gripping surface must offer sufficient friction to firmly hold onto the membrane, but also be delicate enough to avoid specimen tearing.

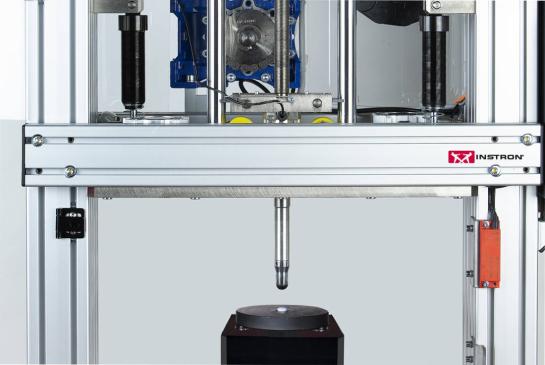

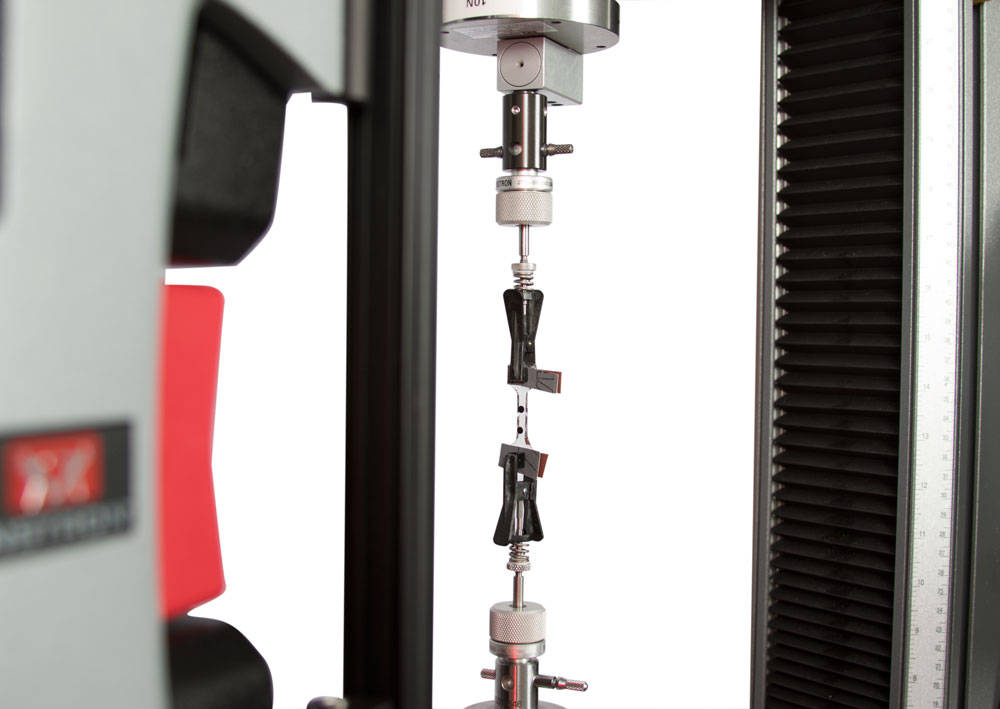

Recently, we were asked to recommend a gripping solution for testing of wet polymeric membranes. In this test, the polymeric membranes were first soaked in water for up to 20 minutes to allow them to soften and swell. The wet specimens were then tested using the 5965 dual column electromechanical machine equipped with pneumatic side action grips and rubber coated jaw faces. Since these membranes are very delicate, the clamping pressure must be carefully controlled as excessive high pressure can cause the specimen to fail prematurely when the grip closes.

Because the specimens are wet, corrosion resistant grips or fixtures should be used. Our 3 Software®Bluehill provides both the test control and results required.