Our History

Instron: 80 Years of Excellence

Instron has been a world leader in materials testing since our foundation in 1946. Though many things have changed over the years, our devotion to testing excellence has always remained the same. Here's a look back at some of the highlights from the past 80 years.

How It Started

With silk being unavailable due to the war, scientists in the early 1940s were desperate to identify substitute materials that could be used for the construction of parachutes. Two of these men were Harold Hindman and George Burr.

Working out of his lab at the Massachusetts Institute of Technology (MIT), Harold Hindman realized that no testing machine available was capable of adequately evaluating new textiles such as nylon and rayon. His colleague George Burr, however, was working with a new device called a strain gauge that was being used to evaluate building materials used in earthquake zones.

Harold and George put their heads together and created a new testing instrument that used a strain gauge as a load cell transducer. This innovation allowed the new machine to test at a much higher frequency than anything else available at the time, perfect for evaluating textiles.

Harold and George’s new machine quickly proved its worth by accurately measuring the dynamic mechanical properties of nylon parachute cord and helping to identify it as a viable replacement for silk in the manufacturing of parachutes. In addition to helping the war effort, their prototype testing machine was so successful that they decided to form their own company, Instron Engineering Corporation, in 1946.

The original Instron testing machine incorporated a unique cross-head drive system, which was similar to the radar antenna positioning drive on naval warships.

1950s

To help get started in the early years, Instron entered into a partnership with Matherson Machine Works of Quincy, MA, which provided office space and employees. The first lot of Instron testing systems were produced in a mattress warehouse owned by Matherson. Since everyone was working around the clock, the mattresses came in very handy during nap time!

One of the first Instron systems to be delivered was to the Textile Research Institute in Princeton, New Jersey.

During the mid 1950s, Instron designed and introduced its first tabletop tester. For the first 15 years of operation, three of the major components in the machines were WWII surplus parts.

Instron’s first venture into automated readout and data acquisition for testing paper was in 1957, long before personal computers arrived on the scene. Automated printout of data was accomplished by a solenoid-operated mechanical NCR calculator designed by Instron engineers. During this time period, Instron also built an automated pencil lead testing machine before any industrial robots existed.

After relocating several times to rented facilities around the Boston area, it was finally time for Instron to build a home of its own. In 1957, Harold and George laid the cornerstone for a new, state-of-the-art factory in Canton, MA.

The move to the new Canton facility took place over a single weekend, and by Monday morning the factory was operating at full capacity.

1960s

In 1960, Instron expanded to the United Kingdom, founding Instron Limited in High Wycombe, UK. Instron Ltd. was established to cope with the growing demand for manufacturing, marketing, sales, and servicing requirements in Europe.

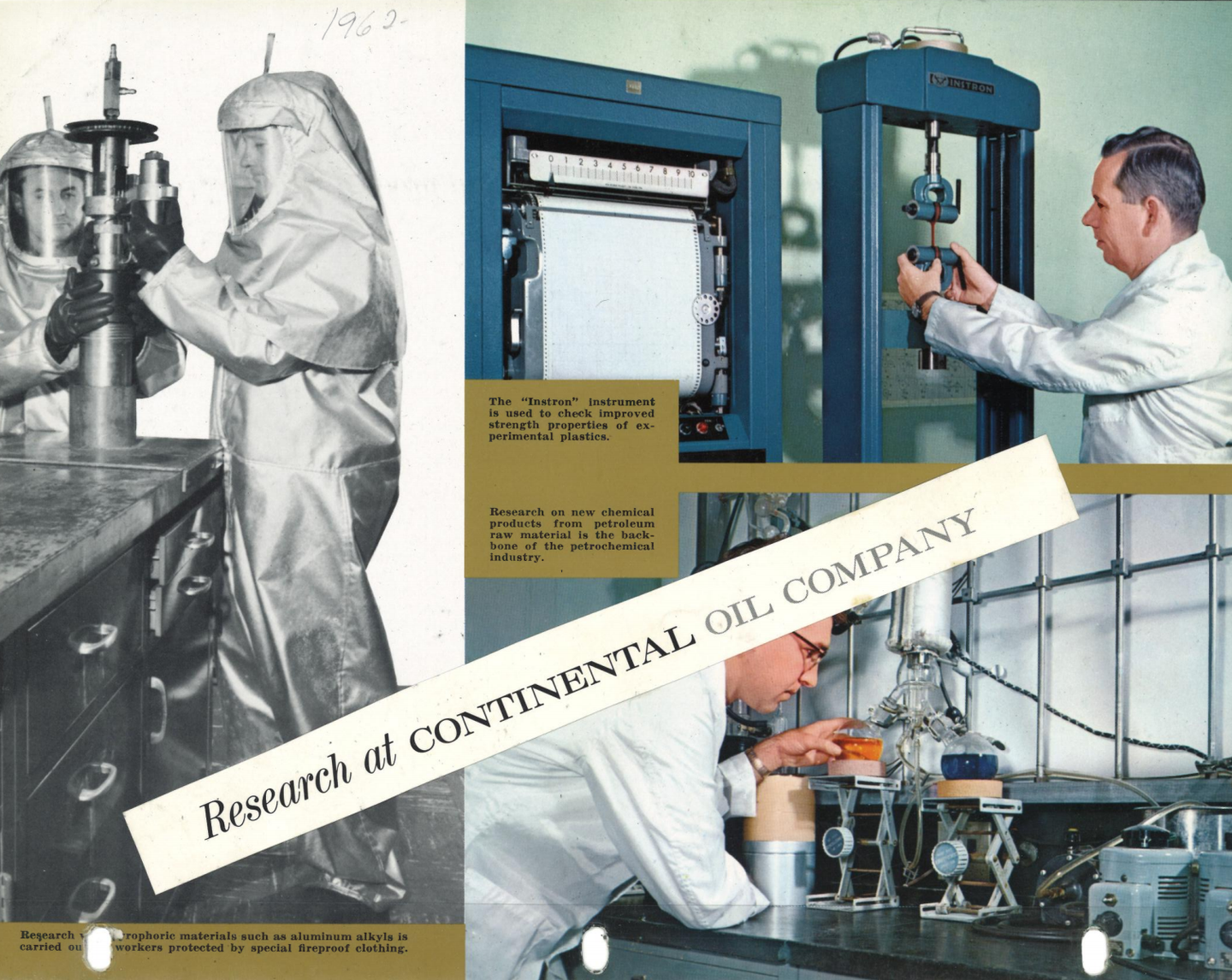

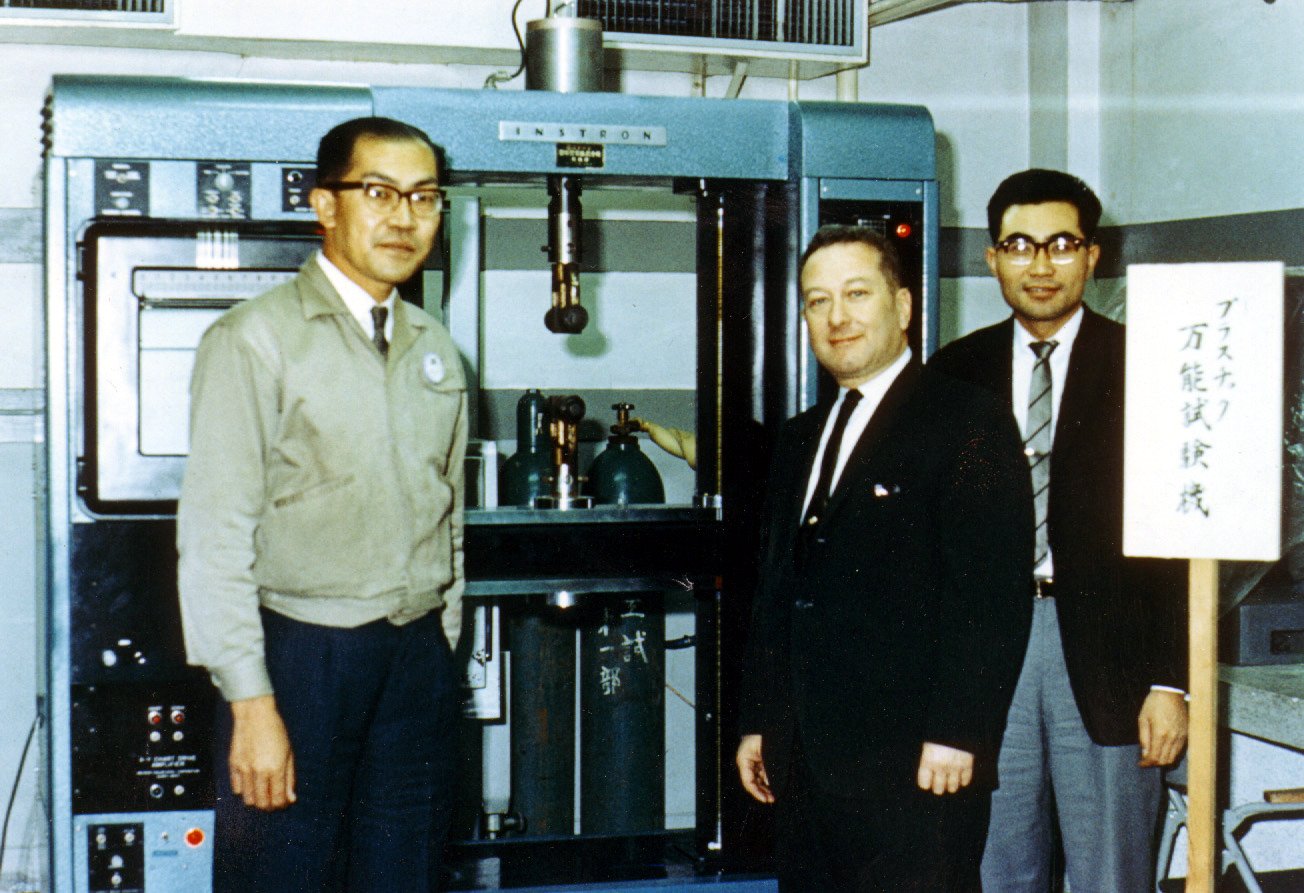

During the 1960s, materials technology was advancing at a rapid rate. The world’s most cutting-edge companies relied on Instron to help them break new ground.

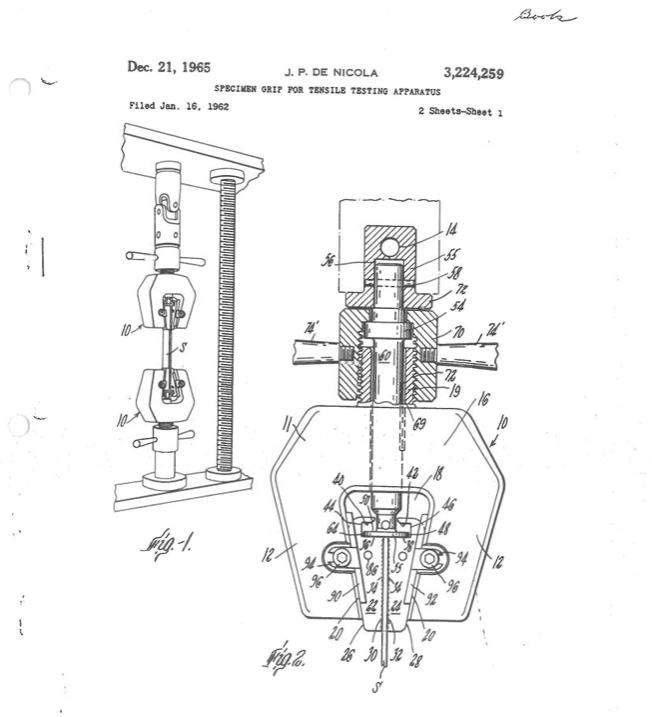

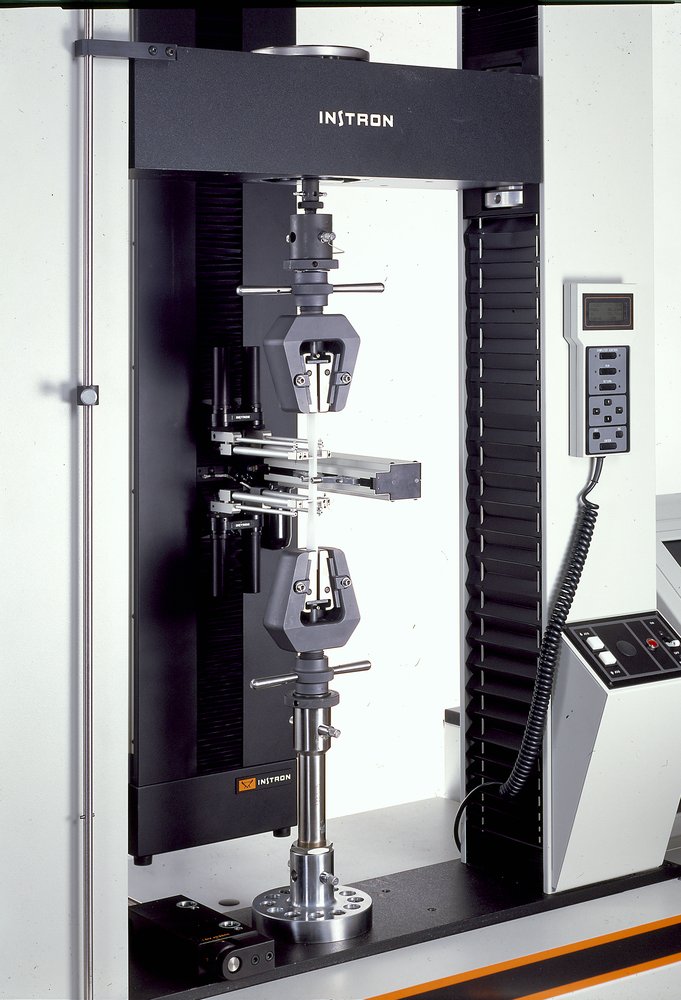

The 1960s saw the development of some of our most popular products, including the earliest versions of our mechanical wedge grips and pneumatic grips.

In 1964, Instron debuted the first optical and long travel extensometers, as well as our first environmental chamber. The following year, we introduced the first load strain control system for electromechanical machines.

Other Instron achievements in the 1960s included the first digital test recording device — an incremental punched tape system — and the data analyzer in our Model 1161, which was the first use of a microprocessor in a materials testing system.

The name “Instron” is a portmanteau of the words “instrument” and “electronics.”

In 1965, Instron Japan Company Ltd. was founded to support the marketing and service requirements for the Asia-Pacific region.

1970s

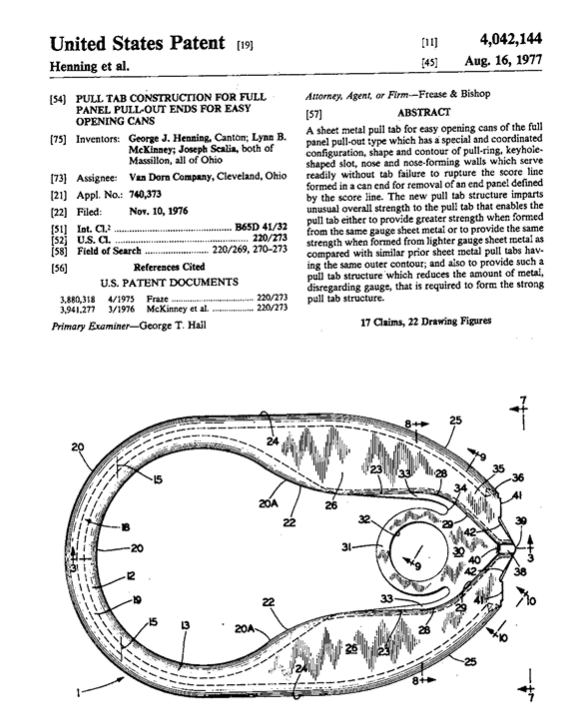

As Instron systems grew in popularity, they started being referenced in patents for all types of products and materials, including this one for pull tabs on aluminum cans.

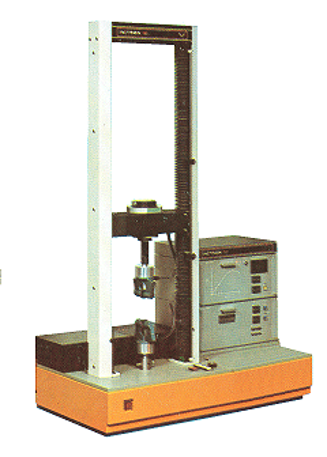

The 1970s marked some of Instron’s most important contributions to the automotive testing industry, with the invention of our seat belt testing grips and the first road simulation machine. We also began production of our popular 1120 Series tabletop systems.

The two characters immortalized in Instron’s logo are known as Mo and Jo — representing the company’s founders, Harold Hindman and George Burr.

In the 1970s, we introduced a shaker system for vibration testing. Our first shaker systems were introduced both as stand-alone machines and as a composite system alongside a servohydraulic test frame.

When New England was hit by the famous Blizzard of ’78, Instron headquarters was buried under more than three feet of snow. The building was commandeered by the Red Cross as an emergency evacuation site, and more than 400 people were housed and fed at the Instron factory for five days until the roads became passable.

1980s

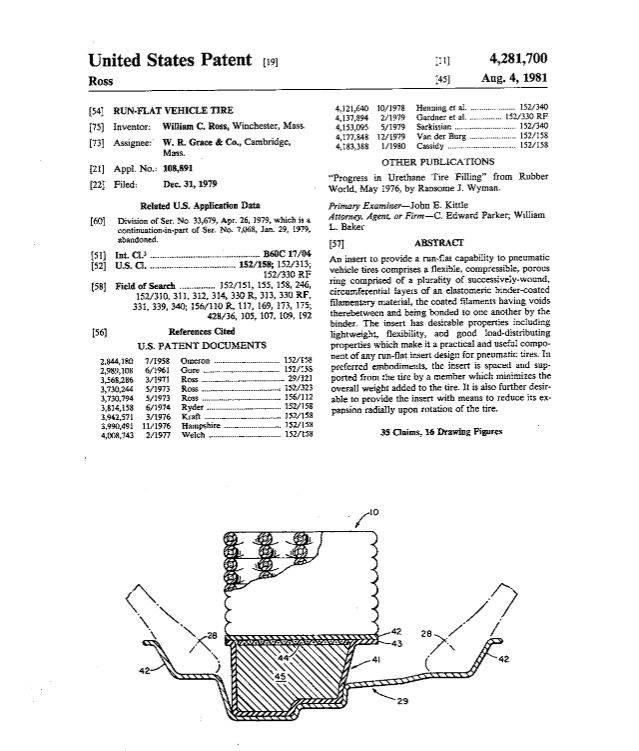

Run-flat tires are now common on light trucks and passenger cars because they reduce the need for vehicles to carry a spare. In this 1981 patent, an Instron applies 1,000 pounds of compressive force to a punctured specimen in order to test the strength of the design.

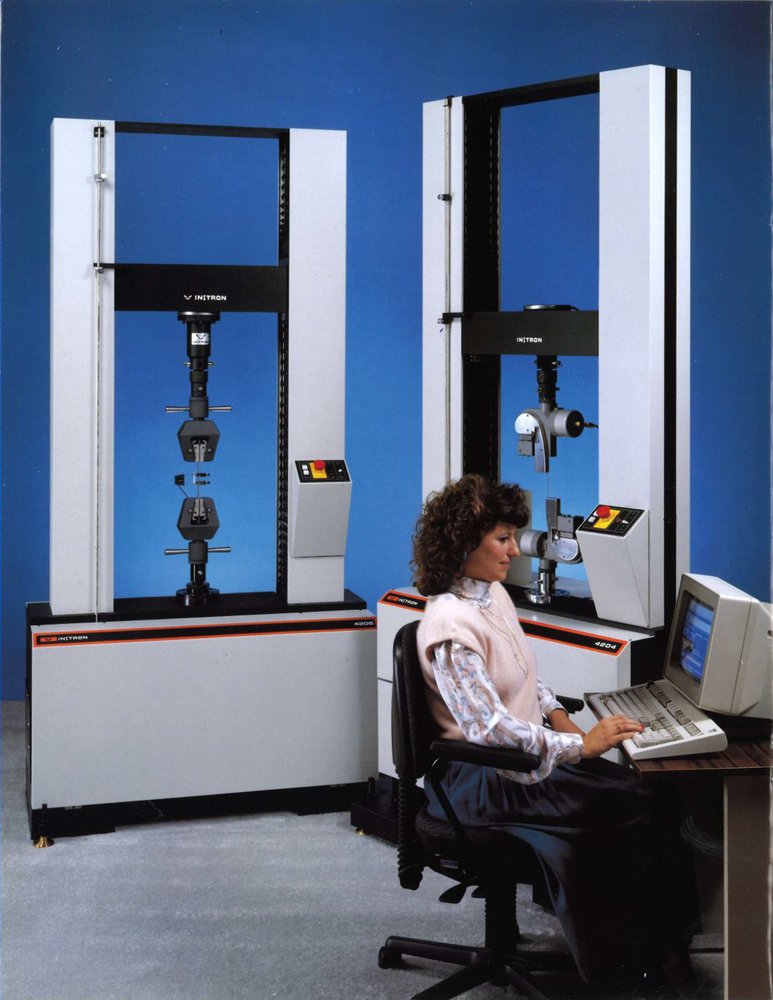

As computers became more sophisticated, we introduced the first fully digital electromechanical testing system (4200) and the first fully digital servohydraulic system (8500). We also debuted our popular Testmaster robotic system, the first commercially available, fully automated testing system.

The 1980s also saw the development of several new products, including biaxial servohydraulic machines and the first automatic extensometer.

Over the years, Instron has made several significant acquisitions, greatly expanding our range of materials testing systems and giving us more than 500 years of collective experience in the industry.

The first of these purchases was Severn Furnace Limited, purchased in 1989 from Severn Science Ltd. This organization had built its reputation on the design and manufacture of advanced high-temperature furnaces and thermal equipment, and we were excited to welcome them into our family.

Instron Korea was established in 1982, and we opened our first sales office in China the following year.

1990s

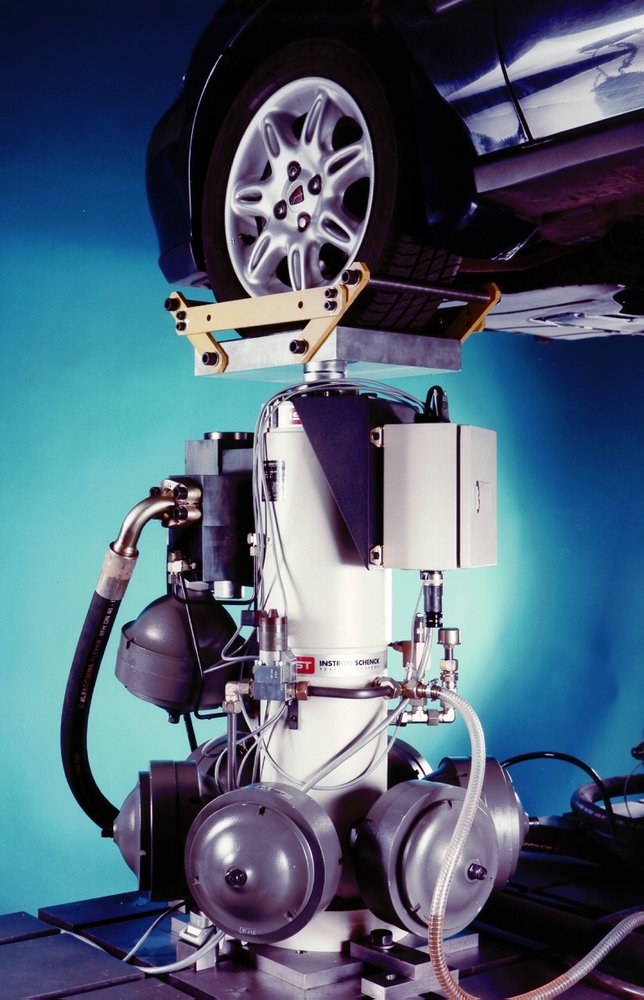

Instron purchased the structural testing business from Schenck Testing Systems in 1996. This expanded our portfolio of products that test automobile performance, which became known as Instron Structural Testing (IST).

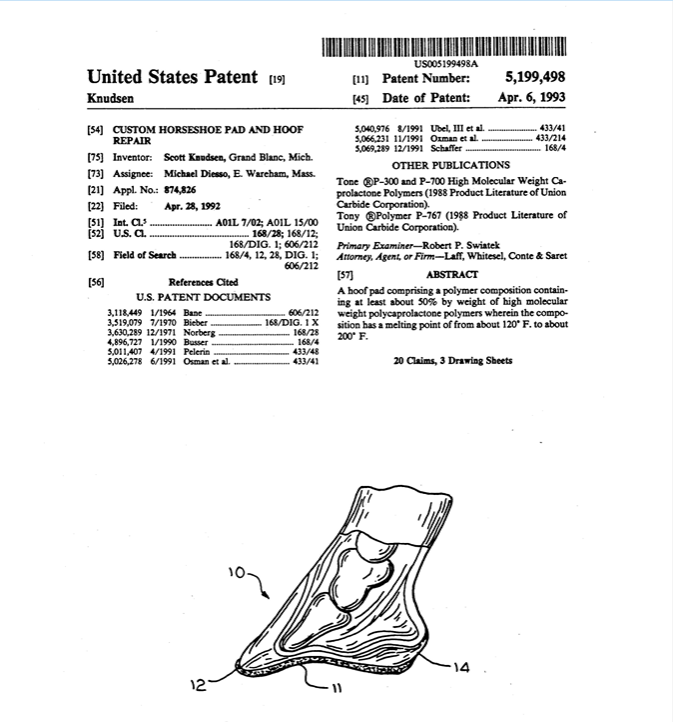

Hoof pads are often used in conjunction with horseshoes to treat various pathologies within a horse’s foot. Pad materials must be malleable enough to conform to the animal’s foot while also strong enough to support its weight. This 1993 patent uses an Instron rheometer to analyze polymers for a new custom-fitting hoof pad.

Instron acquired Dynatup in 1997 and incorporated its excellent impact testing equipment into our product portfolio.

In 1998, Instron purchased SATEC Systems Inc. Today, the SATEC brand is known as the Industrial Series for Instron’s hydraulically powered universal materials testing machines. Learn more about the history of SATEC.

2000s

In 2005, Instron was acquired by ITW as the foundation of its test and measurement platform. We also moved our factory from Canton to Norwood. The new facility was just a few short miles away from our original location, but try telling that to the guys who had to move our deadweight stack…

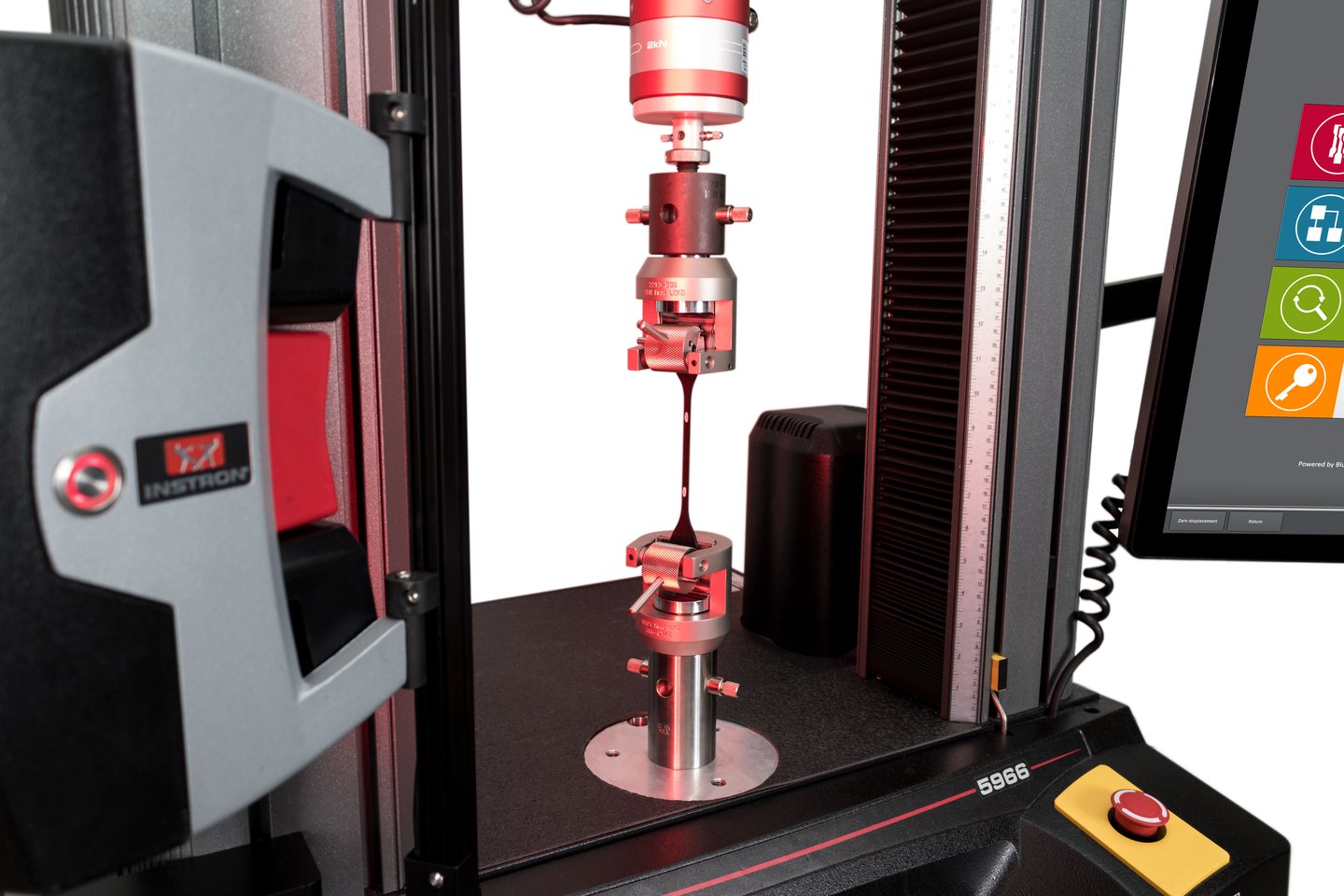

The new century brought several exciting new product innovations, including the ElectroPuls Series for electrodynamic fatigue testing and our popular 5900 Series systems.

In 2008, Instron acquired CEAST. This Italian-based company is well known for its comprehensive testing equipment and includes systems for assessing the impact, rheology, and thermomechanical properties of polymers.

As computing moved forward at a breakneck pace, Instron kept up by introducing the first generation of our Bluehill and WaveMatrix software for static and dynamic testing systems.

An Instron 8870 testing system was featured on CSI Miami Season 2, Episode 11. Because nobody on the show knew how to operate the system, sales specialist Kent Wallace was recruited to be on camera. The episode, “Complications,” aired on January 5, 2004.

All of our static testing systems are manufactured at our facility in Norwood, MA. The building also houses our famous deadweight stack and a top-notch applications lab where visitors can see our systems in action.

2010s

In 2015, we launched the AT3 three-axis non-robotic automatic tensile testing system for plastics and other lightweight materials. These fully self-sufficient systems can run for hours without human operators.

Catheters, feeding tubes, and other medical devices are held in place inside the body by small inflatable pouches, known as balloons. In this 2019 patent, an Instron system was used to measure balloon elongation.

In 2017, we introduced Bluehill Universal, the first materials testing software designed for touchscreen interaction.

How It's Going

In 2020, Instron launched the latest generation of mechanical testing systems, the 6800 Series, which offers up to 5 kHz data acquisition and 0.5% accuracy down to 1/1000th of load cell capacity. It also comes equipped with our Operator Protect system architecture to make testing simpler, smarter, and safer than ever before.

Instron is always around to help when things get tough. This 2021 patent uses an Instron system to perform a shear test on carbon nanofiber tubes. These tubes are part of an air filter designed to fight SARS COV-19.

Over the years, Instron systems have been cited in more than 18,000 patents and have helped shape progress in the aerospace, automotive, biomedical, electronics, and raw materials industries.

Eighty years after Harold and George first put a strain gauge inside a load cell, Instron has become the world standard for materials testing systems. Over the years, we have installed more than 50,000 systems worldwide, and 95% of the world’s largest manufacturing companies use our systems to meet their testing needs.