PLASTICS TESTING ESSENTIALS

COMPLIANCE AND DATA INTEGRITY

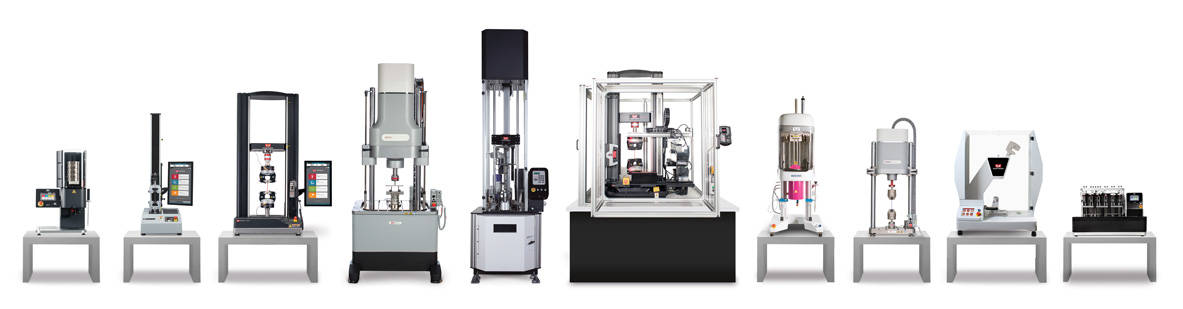

Instron takes an active approach to innovations in the materials industry, and our applications experts are continually working to develop new solutions in anticipation of future trends. To help simplify test setup and ensure your tests remain simple, repeatable, and error-free, Bluehill® software includes prebuilt test methods for many of the most common plastics testing standards including ASTM D638, ISO 527, ISO 306, and ISO 6603. All Bluehill software is designed with robust security features to ensure the integrity of your results, while Bluehill Universal for static testing machines allows for centralized, remote management of multiple systems across multiple labs, streamlining testing processes across your entire organization.

THROUGHPUT AND REPEATABILITY

Many plastics manufacturing environments require high volume testing, making them an excellent candidate for automation. Though automation can be adopted at any level, plastics labs typically see the most benefit from robotic or semi-robotic systems that can operate for hours with minimal human intervention.

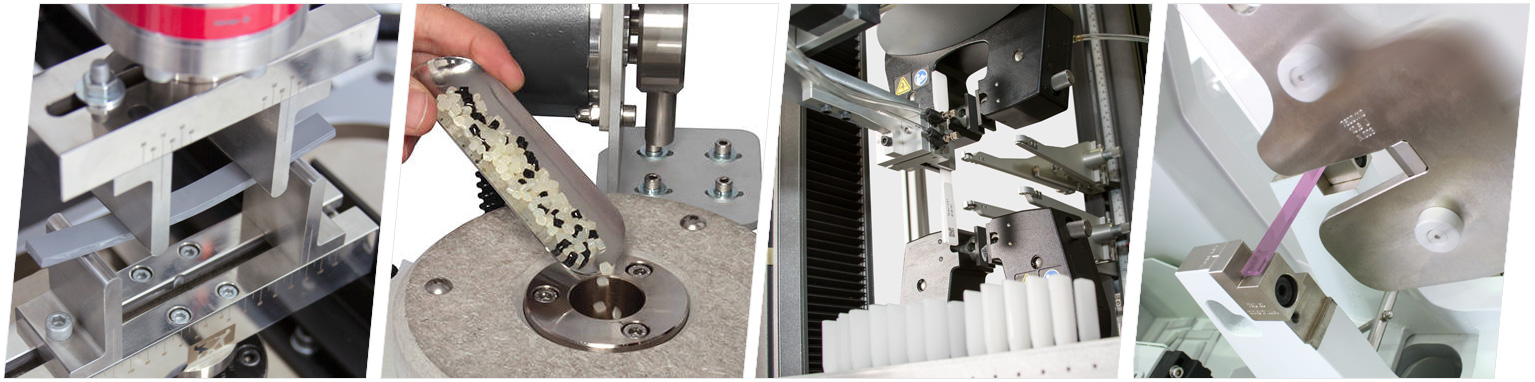

Improving Throughput for Static Testing

Instron’s AT6 and AT3 are fully robotic and semi-robotic options that can be configured for tensile or flexural testing of plastics to a wide range of ISO and ASTM standards. These systems provide high throughput and repeatability while freeing up the operator to perform other value-added tasks. In instances where full automation is not feasible, fixtures such as pneumatic grips, automatic extensometers, and built-in alignment devices - along with software functionality such as choice inputs, also improve throughput while significantly reducing variability in results.

Increasing Productivity for Puncture Impact Testing

Maintaining high productivity can be challenging when performing large volumes of puncture impact tests according to ISO 6603 and ASTM D3763 standards. The Instron 9450 Series drop weight impact tester is equipped with either a manual pivoting specimen feeding system or an automatic specimen feeding system. Both devices increase productivity while decreasing repetitive operator actions associated with manual testing.

TRENDS IN PLASTICS

HIGH PERFORMANCE POLYMERS

High performance polymers can be used in a broader range of applications because of their superior thermal stability and chemical resistance. This allows for plastic components to be used in aerospace, medical, defense, and other industrial applications where the conditions can be extreme which previously would have discouraged the use of plastics. This is achieved using stabilizers and adding reinforcing materials like glass or carbon fibers. These materials are often stronger and stiffer than traditional plastics and will have higher ultimate tensile strength (UTS) and modulus values. Environmental chambers are used often during mechanical testing to replicate extremely high or low temperature applications.

ADDITIVE MANUFACTURING

3D printing is gaining ground in many industries as a revolutionary new way to manufacture intricate and custom polymer products. Additive manufacturing also presents a number of unique challenges that need to be addressed by thorough mechanical testing in order to properly characterize parts and materials:

- The printing process creates many opportunities for internal weaknesses that are not seen in extruded or injection molded parts

- High variability in additively manufactured parts requires testing to be performed on larger sample sizes

- Variations to printing and post processing methods can influence material performance, leading to more variables being tested and even larger volumes of data to manage

Related Content

- Testing, Testing, 1, 2...3D White Paper Learn How To Overcome Testing Challenges for Additively Manufactured Products

- How to Achieve More Repeatable Test Results in 3D Printing Applications | Blog Article for HDT and Vicat Testing Applications

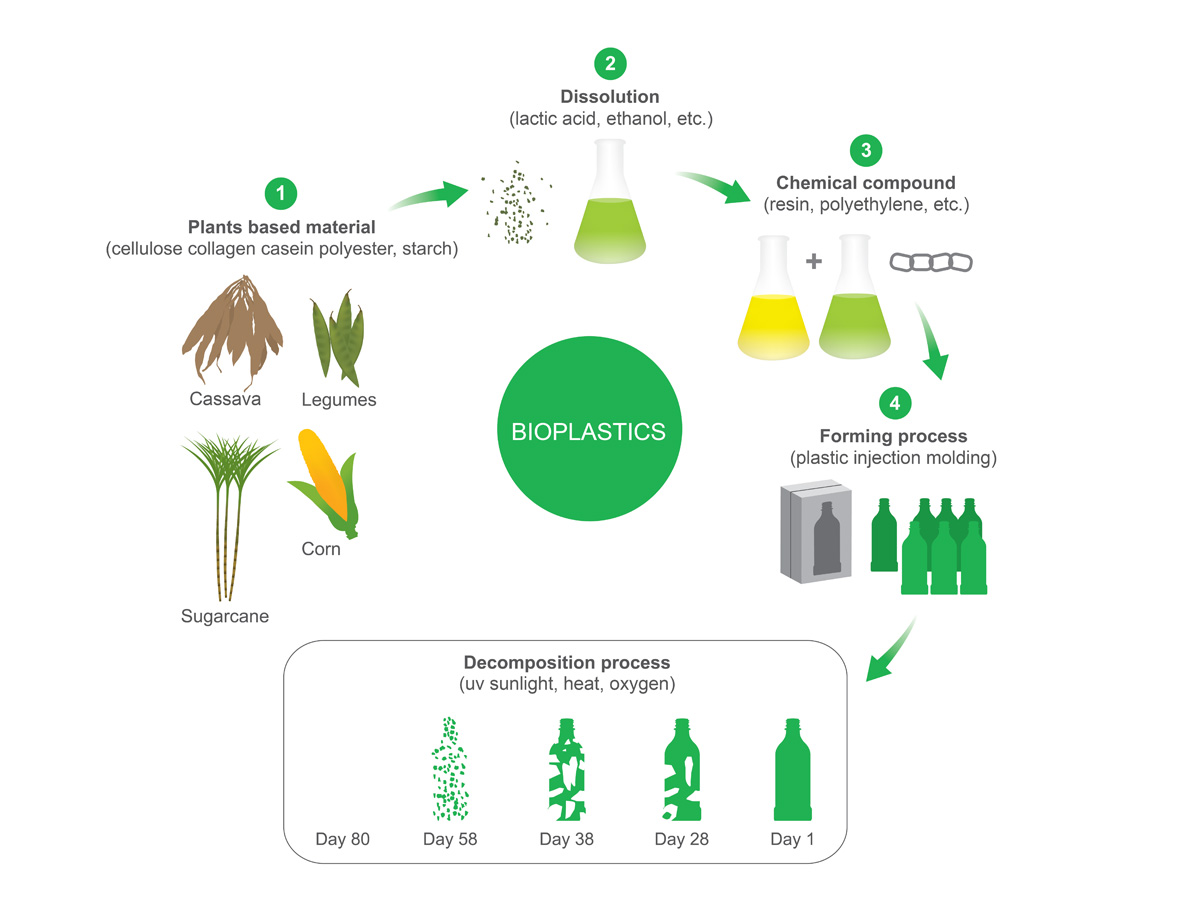

GOING GREEN

Many consumer product companies have made pledges to reduce the amount of non-recyclable plastics in their products. Along the same lines, many companies have also pledged to use chemically recycled plastics in their products. Either way, there is a push to choose more sustainable options when using plastics, especially in single use items like packaging.

Another way to benefit from the upsides of plastics while choosing sustainable options is to utilize bioplastics. Bioplastics aren’t made of fossil fuels like other plastics, but are derived from plants like corn, potatoes, or sugarcane. Some are biodegradable and compostable.

Creating more sustainable options is a trend for the plastics industry. Mechanical testing is needed anytime a product changes its material type or manufacturing process to ensure the end-use application isn’t negatively impacted.

Related Content

- Disposables Drive the Rise of Bioplastics in the Healthcare Industry | Featured Article in Medical Design Briefs Magazine

PLASTICS TESTING SOLUTIONS

PLASTICS TESTING STANDARDS

The following is a listing of the most common international standards for testing plastic materials.

- ASTM D1004 | Tear Resistance (Graves Tear) of Plastic Film or Sheeting

- ASTM D1238 | Melt Flow Rates of Thermoplastics by Extrusion Plastometer

- ASTM D1525 | Vicat Softening Temperature of Plastics

- ASTM D1621 | Compressive Properties of Rigid Cellular Plastics

- ASTM D1708 | Tensile Properties of Plastics by Use of Microtensile Specimens

- ASTM D1894 | Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

- ASTM D3763 | High Speed Puncture Properties of Plastics Using Load and Displacement Sensors

- ASTM D6272 | Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending

- ASTM D638 | Tensile Properties of Plastics

- ASTM D695 | Compressive Properties of Rigid Plastics

- ASTM D790 | Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

- ASTM D882 | Tensile Properties of Thin Plastic Sheeting

- ASTM F1306 | Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates