Automated Testing Systems

Automated Testing Systems

Instron's range of automated testing systems empower labs to improve throughput, repeatability, and safety while freeing up skilled operators to focus on other valuable tasks. Available as either a complete turnkey solution or as modules fitted to existing Instron testing instruments, both options are tailored to your program’s specific requirements and provide the broad control and handling capability needed to a test to a wide range of applications. Standardized systems are available for tensile, flex, and compression testing of plastics, thin films, metals, and components.

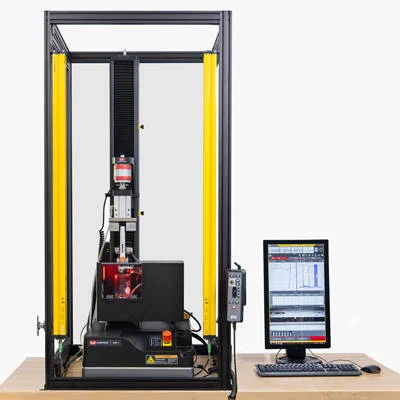

The Instron TestMaster AT3 automated testing system utilizes an innovative design for the automatic tensile, compression, and/or flexural testing of a variety of plastics, thin films, elastomers, foils, foam, and more. Meeting the testing requirements of many different testing standards including ASTM D638, ASTM D790, ISO 527, and ISO 178, this system offers many of the benefits of our robotic AT6 systems but with a smaller footprint.

The Instron AT6 Automated Testing System utilizes an innovative design for the automatic tensile and/or flexural testing of metals, plastics, thin films, components, elastomers, sutures, and composites. Conforming to ISO and ASTM standards for a wide range of materials, this system has a flexible platform to deliver high throughput with repeatable results for a variety of testing needs.

The AT2 Automated XY Stage can be installed on any new or existing 6800 or 5900 Series universal testing system to automate compression, tensile, and flexure testing of devices or components with multiple test points or multiple components with repetitive test points. These systems are widely adopted in the biomedical and electronics industries to test a wide range of materials, devices, and components.

The Instron Automated XY Stage for the ElectroPuls test instrument is designed for repetitive and multilocation durability testing. It can easily be adapted to suit many different testing scenarios with many different specimens, devices, and components, including electronic devices, touch-sensitive panels, keyboards, performance footwear, and clothing..

Developed in close partnership with pharmaceutical device manufacturers and CDMOs, Instron’s latest generation Autoinjector Testing System can perform full functionality testing on a wide range of drug delivery devices – such as needle shield and button-activated devices, as well as safety syringes. This system measures a variety of essential performance requirements, including cap removal, dose accuracy, activation force, injection time, needle depth, click detection, and needle guard lockout – allowing labs to meet internal quality requirements and international standards such as ISO 11608.

Instron’s Automated Carousel Testing System utilizes an innovative, adaptable design for testing of medical vials, cartridges, and pre-filled syringes. The small footprint allows it to be put on standard lab benches adding automation to even the smallest labs. It is designed with easy wipe-down surfaces and stainless steel covers for biomedical environments. Commonly configured to automate testing of residual seal force (RSF) and compression testing.

The CT6 cobot testing system introduces the benefits of automation to the testing of biomedical devices and components. This system pairs a collaborative robot with a 6800 or 5900 Series universal testing system to increase the efficiency of small to mid-sized testing labs that require a high degree of flexibility in their testing systems. The CT6 is designed to handle a wide range of medical components including drug delivery, sample collection, and wound closure products.

The 6800 Series Multi-Station System offers enhanced throughput with its ability to perform simultaneous, independent tests on up to five separate specimens using a single load frame. Based on our standard 68TM-30 testing frame (30 kN capacity), this system is especially suitable when test times are lengthened due to high elongation or slow test speeds. If your test methods and expected results are similar for the specimens you are testing, this system is the ideal solution for cost-effective and efficient materials testing. This system will help labs keep up with the high throughput demands of high speed or multiple production lines.