Migrate to newer Drop Weight Impact Testing technology to minimize risks

Dynatup 9200 and Fractovis 6785 Transition into Phase 4 from June 30th, 2022

Years ago, you chose to partner with Instron for your impact test program to mitigate risk from both a product and regulatory perspective while generating accurate and repeatable data. You also wanted to facilitate new product development, ship quality products, and meet your customer lead times to achieve your revenue goals. And you wanted to become more efficient in your testing—simplifying processes and reducing the number of people in your lab.

By working with us, you have met these goals!

Unfortunately, it’s becoming untenable for Instron to support CEAST Fractovis model 6785 and Dynatup 9200 Series Drop Weight Impact Testing systems. These units were designed in the 1990s and last produced in the 2000s. As a result of the technological evolution, the parts that were state-of-the-art at that time are now outdated and some are no longer produced by our suppliers. Moreover, drawings and technical datasheets are not available anymore. Replacing singular parts that break is increasingly expensive. Adding to our concern, some of your systems may be running an older operating system, which is no longer receiving security updates from Microsoft.

How would your organization be impacted if your impact testing systems were unavailable?

The Risk of No Change

Without a plan for migrating from your CEAST Fractovis and Dynatup Series systems, you could experience unplanned and extended downtime. Not having the latest technology —or replacing your Instron system with a product from a different supplier— could introduce unnecessary variation in test results. Additionally, your operators—who are increasingly from a younger generation—may be less attracted to working with equipment that has an older user interface. And without security updates to the OS, you’re exposed to a data breach. You face a greater risk of budget surprises, defective products, and delayed revenues.

How much time and money would a product recall because of invalid tests cost your company?

Why Evolve

By establishing a solid migration plan with Instron, you can transition your impact testing without risk. You will be able to:

- Make your system easier to use and allow your people to produce faster results

With high turnover among research laboratories, Bluehill Impact Software ease of use allow to reduce learning curves and its intuitiveness provides well-trained users in a very short time. Bluehill Impact software with its pre-configured test methods, immediate access to results and graphs together with the high-resolution data acquisition chain, ensures the accuracy of the force measuring system. - Extend your current testing infrastructure to achieve more value for your customers

With 9450 Bluehill Impact Software and High-Speed Camera, customer can perform advanced mechanical evaluations. With tensile-impact accessories and Digital Image Correlation software, it is possible to evaluate the longitudinal strain of the specimen when impacted under tensile-Impact conditions. - Satisfy your customers timing expectations

Our new 9450 AutoMate Software module allows to customize how the specimens in the feeder are tested, assigning different test velocities and temperatures to a single batch of specimens. These solutions allow you to reduce operating cost and save your operators’ time. - Reduce the time to repair your equipment

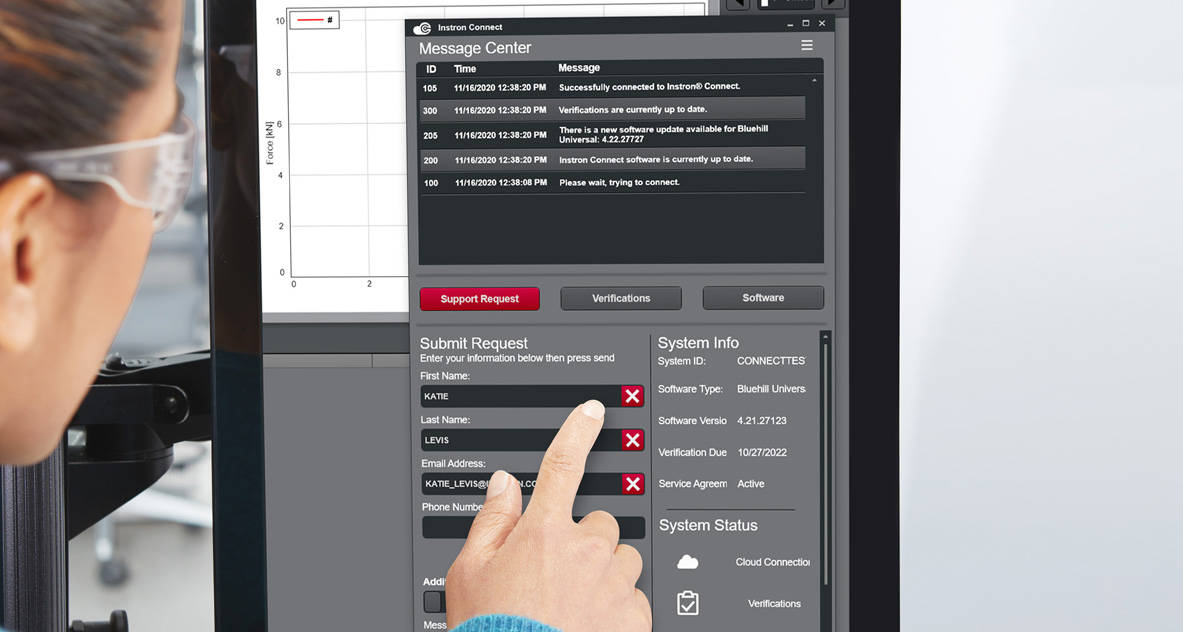

Our new systems allow for remote diagnostics and were engineered with support technician input and specified repair times as a design objective. By evolving with Instron, you will more accurately pinpoint problems. Thanks to the ready-to-ship Field Replacement Units (FRU) Instron service engineers can replace parts faster minimize downtime and the impact on your business. - Preserve your technical support and on-site service

By evolving with Instron, your existing service will evolve into a more secure testing platform: you can benefit from new interesting services such as Instron Connect with the Advanced Remote Tech Support and on-site accredited calibration. Moreover, you can continue to rely on those Instron professionals who already know the specific needs and processes of your organization and with whom you have established a strong working relationship—leading to greater peace of mind.

Find out more on the 9400 Series Drop Weight Impact Testing machines.

Several CEAST Fractovis/Dynatup Series customers have already completed the transition to the new technology.