ASTM A370: Mechanical Testing of Steel Products

Tensile Testing of Metals

ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals. It is used by many industries such as construction and automotive manufacturing where safety is dependent on the quality of materials. In addition to tension tests, the standard also outlines charpy impact, bend, and Brinell and Rockwell hardness tests on metals, which are further discussed by standards ASTM E-23, ASTM E190, ASTM E10, and ASTM E18.

This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. This guide is not considered an adequate substitute for reading and following the full standard.

Differences Between ASTM A370 and ASTM E8

Standard At A GlanceMaterials

- Metals

Test Types

- Tension

Standard

- ASTM A370

ASTM A370 shares the same testing equipment and test methods as another major metals testing standard, ASTM E8. A370 differs from E8 in that it further defines the specimen characteristics of steels specific to several different product types. These products discuss the testing of bar, tube, fasteners, and round wire, and are included in the annexes to ASTM A370 along with some procedural clarification. It is important to note that although the annexed sections are supplementary to the general section of the standard, the product standard often prevails in the event of conflict.

What Does it Measure?

Though ASTM A370 references different test types, tensile testing is the primary focus. The most commonly measured properties are the following:

- Modulus of Elasticity – A measurement of a material's resistance to elastic deformation

- Yield Strength - The stress at which a material becomes permanently deformed

- Tensile Strength - The maximum force or stress that a material is capable of sustaining

- Reduction of Area - A measurement of the ductility of a material

- Total Elongation – A measurement of the percentage increase in length after failure

Materials Testing System

Because ASTM A370 testing is conducted on such a wide variety of steel products and specimen geometries, system force requirements can differ greatly. Instron's Industrial Series offers test frames suitable for testing machined stainless steel rounds (300kN) all the way up to thick wall tubular products (2000kN). The Industrial Series load frames include high-stiffness ball screws and columns, strain gauge load measurement, and backlash elimination for durability. These features contribute to better performance by producing more accurate results and minimizing the energy stored during a test, which is especially evident when testing high-strength materials such as spring wire and large diameter fasteners.

Testing Methods

As with the most common metals testing standards, ASTM A370 describes three types of test controls: Stress Rate Control, Strain Rate Control, and Crosshead Displacement Control. For ASTM E8 / E8M, these types of controls are referred to as Methods A, B, and C. In ASTM A370, tensile test control refers back to the methods of ASTM E8/E8M with the addition of certain calculations specific to the different materials and applications within the ASTM A370 standard. Manufacturers commonly run tests using crosshead displacement for the entire duration of the test, or rely on stress rate control through the calculation of elastic modulus and then switch to crosshead displacement control for the remainder of the test. The video below discusses the Strain Rate Control method in greater detail.

Grips and Extensometers

While there are many different gripping technologies suitable for testing round and flat materials, hydraulic wedge or side-action grips are popular and versatile options, though some of the materials within ASTM A370 (tubing and fasteners, for example) require more specific solutions.

Annex 1 - Bar

This annex covers the specimen dimensions and extensometer gauge length requirements for hot rolled and cold finished bar material for flat, round, square, hexagon, and octagon specimen shapes. Proportional wedge grips are generally recommended when testing bar material. However, due to its extremely high tensile strength, some bar material (particularly the type used to manufacture springs) can can cause serious damage to the jaw faces of a standard wedge grip when encountering slippage during a tensile test. In these cases we recommend a side acting non-proportional grip in order to hold the material more securely during the test and upon specimen failure.

All hot rolled bar specimens require an 8” gauge length instrument for strain measurement as they are full section and unmachined. Suitable options for extensometry are either an Instron AUTOX750 with adjustable gauge length, or a manual clip-on device with a dedicated 8” gauge length such as Instron's E-series W-6280-8 and W-6280-200. Hot rolled material unfortunately cannot be tested using a non-contacting extensometer such as Instron's AVE2 as the flake debris during testing will either cause the gauge markings to fall off the specimen or cause the instrument to lose site of the gauge markings.

Cold finished material specimens do have a section reduced by machining, and as such use an appropriate 2” gauge length extensometer such as the AUTOX750, AVE2, or a manual clip on-device. Class B2 extensometry is suitable for a 0.2% offset yield, but a B1 class device is recommended should a lower percentage yield calculation be required.

Annex 1 also covers bend testing requirements for both hot rolled and cold finished bars. Tests are run on full section material when material dimensions allow, and the annex specifies dimensions for machined specimens when necessary. Bend tests are performed for the purpose of visually inspecting the material for surface cracking and require Instron's W-6810 and W-6812 bend test fixtures.

| ASTM A370 Bar Test Setup | |

|---|---|

Instron 600DX |

|

W-5197 Jaw Faces |

|

AUTOX750 Automatic Extensometer |

|

Annex 2 - Pipe and Tube

When testing tubular products such as full section pipe or dogbone specimens cut from pipe or tube, a proportional wedge grip is an adequate and economical solution. If end-flattening of the dogbone specimens is not desired, we recommend the use of curved jaw sets, which are particularly useful for testing specimens with thick walls and higher tensile strength because they eliminate slippage and increase strain accuracy at the start of the test.

Strain measurement solutions for pipe and tube can be either automatic contacting extensometers like the AUTOX750 or a manual clip-on device such as Instron's W-6280 Series. For testing full section tubular products, the AUTOX750 can accept a maximum specimen diameter of 100 mm with a gauge length of 2". Class B2 extensometry is suitable for a 0.2% offset yield, but a B1 class device is recommended should a lower percentage yield calculation be required.

Annex 2 also describes several compression tests for proving the ductility of certain tubular products including flattening, reverse flattening, crush, flange, flaring, bend, and tranverse guided bend tests. Basic compression anvils and dies can easily satisfy many of these tests with the exception of the guided bend test, for which Instron offers the W-6810 fixture.

Annex 3 - Fasteners

Fastener testing requires specialized gripping accessories that support the head of the fastener and concentrate tensile stress on the threaded portion of the specimen. They consist of bolt holders and washers of various diameter, angle, thread, and pitch to match each specific size of fastener. In the event that a fastener is too large to be tested on a given test system, it is permissible to machine a traditional .505” specimen with standard 2” gauge length for testing. In addition to axial tests, two types of shear tests (double and single) are also important and required by ASTM F-606 and MIL-STD 1312, along with proof testing of nuts with a nut proof mandrel.

Extensometry is generally not required when testing fasteners, though it can be helpful when determining if the material demonstrates any strain. An appropriate choice is Instron's W-E439.

| ASTM A370 Fastener Test Setup | |

|---|---|

Instron 300 LX |

|

W-5155-B Bolt Holder |

|

Annex 4 - Round Wire

Annex 4 focuses mainly on two gripping types for round wire products: a secondary wedge grip and a cam-type snubbing grip. Both of these solutions are considered appropriate for testing lower capacity wire that is also malleable in nature. The gauge length for testing full section round wire specimens is 10". Jaw breaks can be a common challenge when testing this type of specimen, as when specimen failure occurs close to the grips, the results of the test are not considered reportable. Because of this, grip alignment is important. Should strain measurement be required, a 10” gauge length clip-on device is appropriate, as is an automatic solution like the AUTOX750.

| ASTM A370 Round Wire Fixture | |

|---|---|

2714-107 Tire Cord Grip |

|

Annex A5 - Charpy Impact

Charpy impact testing for total absorbed energy is discussed at length in both the general section of A370 as well as in annex A5. This is a required test in the production of most of the steels described within the standard. Specimen dimensions are well-defined, and pictorial examples of the different failure types are included. For greater detail, ASTM A370 references the charpy impact standard ASTM E-23. Instron offers suitable solutions from 300 joules to 900 joules such as the MPX system with Bluehill Impact software.

Former Annexes

In the most recent update to ASTM A370, annex A7 (multi-wire strand) and annex A9 (steel reinforcing bar) have been moved to their respective product standards ASTM A1061/A1061M and ASTM A615. Due to their lengthy inclusion in past versions of ASTM A370, we will still touch on those applications within this guide.

Wire Strand - Formerly Annex A7

7 wire strand is normally used in the production of pre-stressed concrete. It is difficult to test stranded wire without the right equipment, and although a proportional wedge grip is acceptable, a non-proportional side-acting grip is a much better choice for both consistency and results. Per the ASTM A1061/A1061M standard, specimen lengths are 48 inches and require a 24” gauge length strain device for proper measurement of change in length.

Reinforcing Bar - Formerly Annex A9

Reinforcing bar, or “rebar” is another material where specimens do not include a reduced section and thus requires an 8”/200mm gauge length extensometer. A proportional wedge grip is appropriate for this test. In North America the sizing convention is based upon # 8 rebar being a nominal 1”, or 8/8 ths. The largest diameter material included in the product standard within recent years is # 20 thread bar which also includes a tensile strength of 100 ksi. Testing of the largest product yields peak test loads of 720,000 lbs. An additional test under the AC133 standard is a rebar coupling test that runs in a through zero cyclic manner using a dual side-acting, or single side-acting non proportional grip.

Calculations and Results

All calculations required in ASTM A370 testing are already preconfigured into Bluehill Universal. For those who prefer to start from scratch and build their own method, manually input calculations can also easily be configured to test to ASTM A370. The metals methods package also provides pre-built methods to all of the following standards: ASTM E8 / E8M, ASTM 615, ASTM E646, ASTM E517, ISO 6892-1, EN10002, ISO 10113 & ISO 1027.

High Force Universal Testing Machines Brochure

Instron’s high force systems include electromechanical and high-capacity hydraulic testing systems for tension and compression applications. Force capacities range from 100 kN to 2000kN.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

Hydraulic Side-Action Grips (DuraSync)

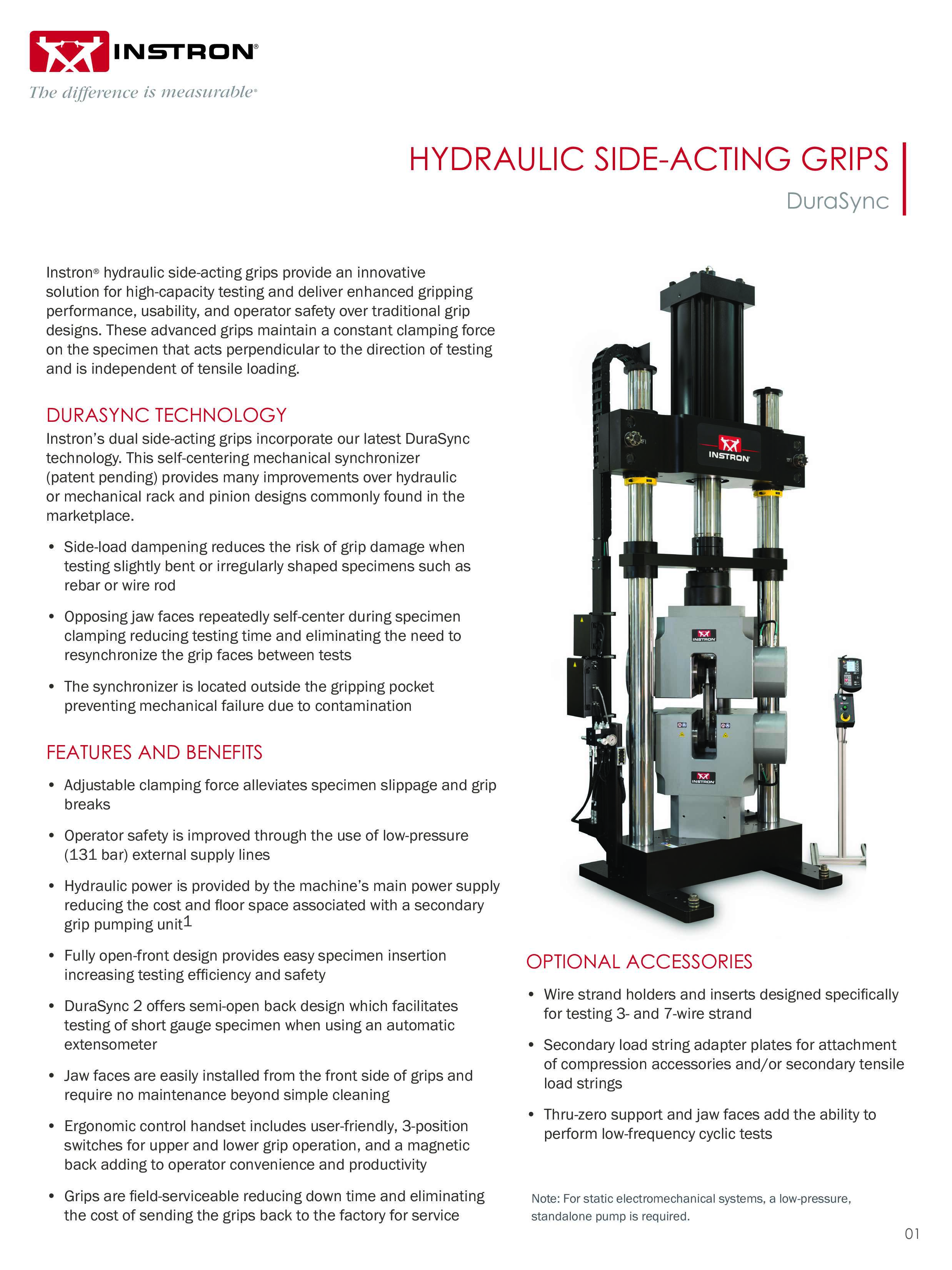

Instron hydraulic side-action grips are designed for high-capacity testing and maintain a constant clamping force on the specimen that acts perpendicular to the direction of testing and is independent of tensile loading.

±100 kN Universal Hydraulic Wedge Action Grips Data Sheet

Instron’s 100 kN hydraulic wedge grips (catalog no. 2743-401) provide an innovative solution for high-capacity testing and deliver enhanced gripping performance, usability, and operator safety.

Industrial Series DX Models

Designed for high-capacity tensile, compression, bend/flex, and shear testing, DX Series testing systems feature a dual test space and single footprint. Understanding the critical importance of operator safety, these frames incorporate high-quality materials, components, and craftsmanship and are ideal for testing metals, wire rod, fasteners, concrete, and wood.

Motorized Impact Testing System (MPX)

The Instron® MPX Series of motorized pendulum impact testers are preferred for metals impact testing to Charpy and Izod standards.