ASTM D695 Compression Testing Rigid Plastics

An Introduction to ASTM D695-15

Written by Daniel Caesar

ASTM D695 is a test method used to determine the compressive properties of un-reinforced and reinforced plastics. It is used alongside its tensile test standard equivalent, ASTM D638. Together, ASTM D695 and ASTM D638 assess the fundamental material properties of polymers that are found in every industry and even every household around the globe. In order to fully understand the test setup, procedure, and results requirements, it is important to review the full standard.

What Does this Standard Measure?

ASTM D695 obtains the properties of a material's compressive strength, compressive yield point, and modulus. The standard specimen for strength determination is a right cylinder or prism whose length is twice its principal width or diameter. If the specimen is too thin, an anti-buckling support jig should be used to prevent the specimen from buckling.

Materials Testing System

Depending on the maximum expected forces, ASTM D695 can be performed on either a single column or dual column universal testing machine such as those available in Instron's 3400 and 6800 Series.

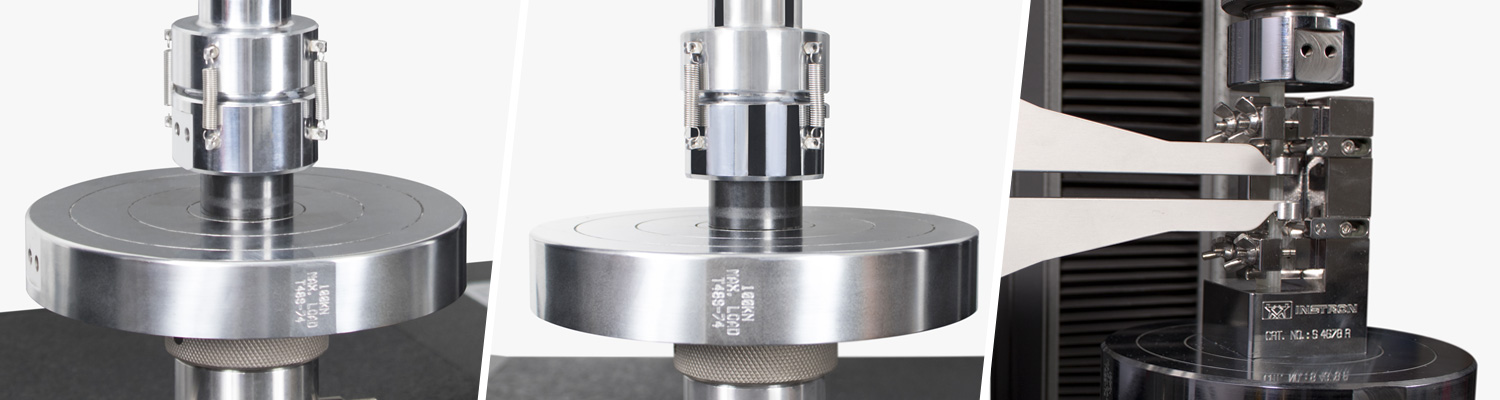

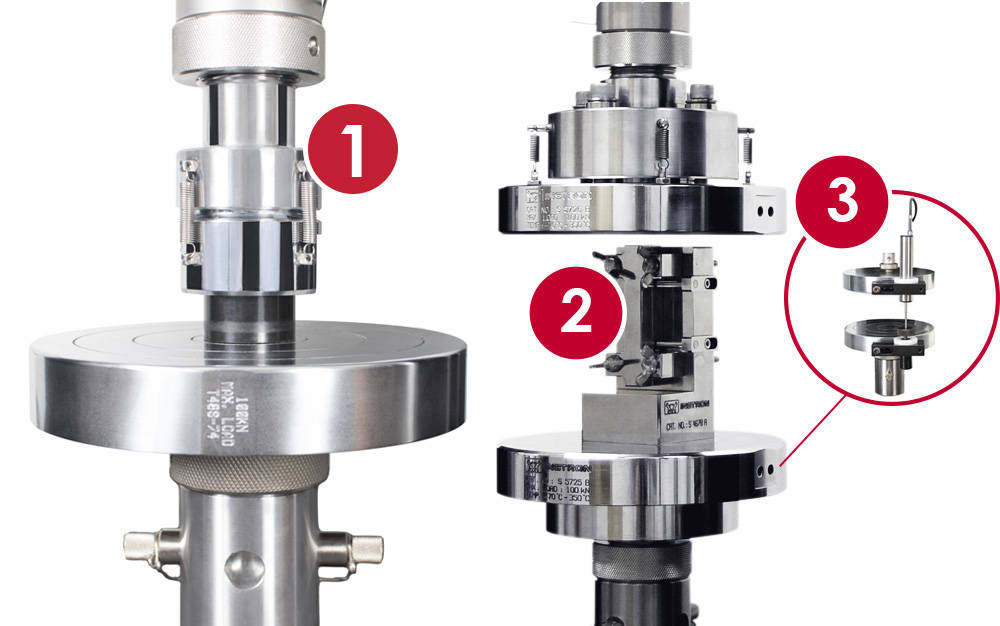

Platens and Accessories

Depending on your application, the following accessories are commonly used for ASTM D695 testing:

- upper compression platen with integral spherical seat (diameters vary from 2" to 8”)

- lower rigid platen of matching size

- 2601-04X series LVDT (linear displacement transducer)

- LVDT mount for platens (2601-071)

Beyond the typical ASTM E4 verification to ensure accurate force data, D695 also requires an ASTM E83 Class B-2 extensometer to measure compressive strain. A popular strain solution is Instron's linear displacement transducer. A more advanced strain solution includes a non-contacting extensometer, such as Instron's Advanced Video Extensometer 2 (AVE 2). The AVE2 is ideal for labs with limited test systems needing to perform a wide variety of tests.

| ASTM D695 Accessories | |

|---|---|

Self-Aligning Spherical Seat |

|

Anti-Buckling Support Jig |

|

2601-04x Series LVDT |

|

Helpful Tips and Tricks

- Compression platens with integral spherical seats are ideal for ensuring platen to platen parallelism, which is a requirement of the standard.

- If the specimen is too thin, an anti-buckling support jig should be used to prevent the specimen from buckling.

- If reporting the modulus calculation, make sure the extensometer and load cell are both verified in the range that the calculation is being made. Labs sometimes unknowingly report calculations outside of the verified range of their devices.

- ASTM D695 is included in the Plastics test method suite available in Bluehill Universal.

- If direct strain measurement and conformance to ASTM E83 Class B-2 is not required, compliance correction should be used to remove the system’s compliance from the crosshead displacement data. Please review the compliance correction whitepaper for more details.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability

3400 Series Universal Testing Systems Brochure

Instron 3400 Series universal testing systems for tensile, compression, bend, and other material property tests.

Anti-Buckling Compression Testing Fixture

This anti-buckling fixture is designed for compression testing of rigid plastics and the shear testing of reinforced plastics. It has also been adapted for use with high strength composites.

AverEdge32 Averaged Transverse Strain Measurement

AverEdge32 is an optional advanced feature of Instron’s AVE3 non-contacting extensometer. Standard extensometers with a single local transverse strain measurement can exhibit stepped changes in transverse strain data, making it challenging to obtain an accurate value. AverEdge32 measures transverse strain at multiple locations along the specimen edges and averages them to produce a smooth and repeatable value, which is essential when calculating the r-value of sheet metal.

2501 Series Compression Platens

These easy-to-install compression platens are precisely machined fixtures that are designed for even distribution of compression loads during a test.

2601 Series LVDT Deflection Sensors

The 2601 Series Linear Variable Differential Transformer (LVDT) displacement transducers are measuring devices that measure the displacement of the load frames.