The Definitive Guide to ISO 178

How to Perform a Flexural Test on Plastic According to ISO 178

Written by Daniel Caesar

Due to their low cost, light weight, resistance to corrosion, and general versatility, plastics have established a significant presence in many different industries. It is important to determine the material properties of plastics in order to characterize their expected behavior in real-world applications. One important property is the relationship between stress and strain while a plastic sample is being bent or flexed: in other words, the flexural properties of the material. To regulate an internationally standardized method for determining this property, the International Organization for Standardization (ISO) developed ISO 178.

This guide is designed to introduce you to the basic elements of an ISO 178 flexure test and will provide an overview of the testing equipment, specimens, and results involved in the standard. However, anyone planning to conduct testing compliant with ISO 178 should not consider this guide an adequate substitute for reading the full standard.

What Does it Measure?

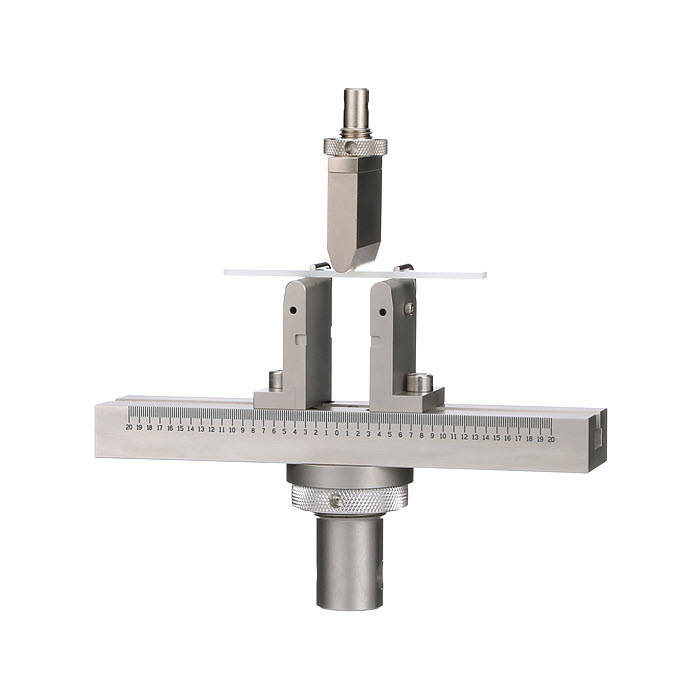

ISO 178 is a test method for determining the flexural properties of rigid and semi-rigid plastics by performing a three-point bend test on a universal testing system. A three-point bend test applies force at the midpoint of a rectangular specimen, which is freely supported at either end. The applied force is measured by a load cell, and the resulting deflection is measured by either the system’s crosshead displacement (with results corrected for system compliance) or by a direct strain measurement device. There are four test types outlined in ISO 178, each specifying a deflection measurement method (i.e. via crosshead or direct strain transducer) and an associated calibration accuracy requirement.

The type of ISO 178 test a lab performs is prescribed by the requirements of its customers, whether they are internal, such as an R&D lab, or external, such as a third party testing lab. It is important to ensure that the specific requirements for your lab are identified and agreed upon by your customers prior to purchasing test equipment and performing testing.

Is ISO 178 the Right Standard for You?

ISO 178 is very similar to ASTM D790, though it differs in several key points:

- ISO 178 requires the use of either a deflectometer or compliance correction in order to determine modulus. ASTM D790 allows modulus to be calculated by crosshead displacement alone.

- Preferred specimen sizes are different, and because test speed is dependent on specimen depth, test speeds between the standards may vary. The preferred depth for ISO 178 specimens is 4 mm while the preferred depth of ASTM D790 specimens is 3.2 mm.

- ASTM D790 allows only one test speed, whereas ISO 178 allows a second (faster) test speed to be used after modulus is measured.

Specimens

ISO 178 specimens are either machined from sheets in accordance to ISO 2818 or prepared via compression or injection molding in accordance to ISO 293/295 or ISO 294-1/10724-1, respectively. The preferred specimen dimensions are specified as:

- Length: 80 mm (± 2)

- Width: 10 mm (± 0.2)

- Thickness: 4 mm (± 0.2)

If the preferred dimensions are not achievable, ISO 178 offers alternative widths dependent on the specimen’s thickness. If the material is anisotropic, both directions are to be tested.

Procedure

ISO 178 testing is usually performed on table model universal testing systems due to the relatively low force capacity requirement. The test machine must be able to maintain a constant test speed between 1 and 500 mm/min within tolerances specified in the standard. All models of Instron’s 3400 Series and 6800 Series testing machines meet the necessary speed accuracy requirements. The force measurement device, or load cell, must meet Class 1 of ISO 7500-1 over the range of forces to be reported. It is important to ensure that your lab is aware of the minimum and maximum test forces so that they select a load cell with an appropriate force capacity and verification range.

THROUGHPUT

For labs looking to increase their throughput, several modifications can be made to the system setup. Automatic specimen measuring devices and specimen alignment devices both increase test efficiency by reducing the amount of manual input needed from the test operator. Fully automated test systems such as Instron's AT3 and AT6 are also available and are designed to incorporate specimen measurement, specimen loading, testing, and removal. These systems can run for hours without requiring any operator interaction. In addition, these systems help reduce variability due to human error.