Non-Ambient Plastics Tensile Testing

Maintaining Specimen Temperature

When working in automotive R&D, awareness of how various materials act at ambient temperature as well as normal operating temperature is important. Many original equipment manufactures have unique temperature requirements that all components need to achieve, for example: -30°C to 80°C. However, engine and transmission components get considerably hotter. It is extremely important to subject the material to these temperatures during testing to understand their performance.

THE CHALLENGE

In order to determine the material's performance at high temperature, it is critical that the temperature of the material is carefully controlled at the required temperature.

OUR SOLUTION

Instron’s 3119-600 series environmental chambers can accurately control the temperature from -150°C up to 600°C (-240°F to 1110°F) making them suitable for materials of all types within the engine bay. Optional roller mounting brackets make it easy to move the chamber in and out of the test space to quickly change between ambient and non-ambient testing. The temperature soak time can be automatically set in Bluehill® Universal and, once complete, the test will start. Alternatively, utilizing TestProfiler you can have different temperatures under different loading conditions during the same test.

Strain Measurement at Non-Ambient Conditions

THE CHALLENGE

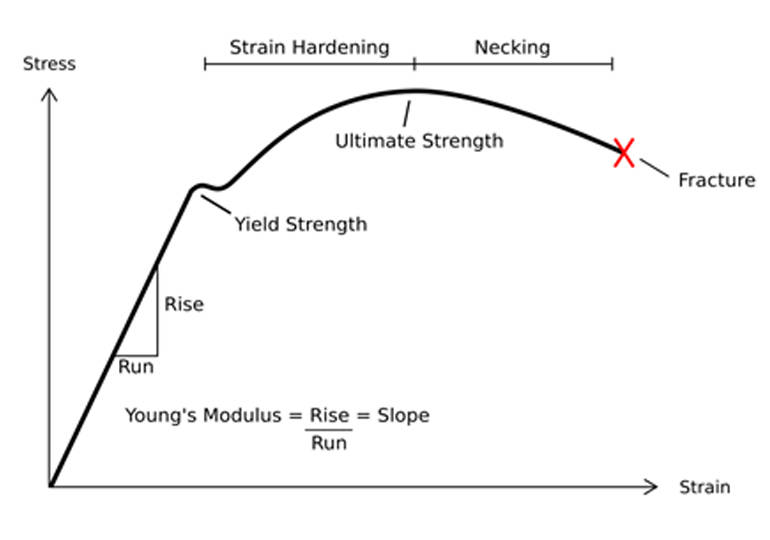

When testing inside of an environmental chamber, calculating the modulus of plastics with a traditional clip-on extensometer can be challenging. When the extensometer needs to be removed during a test, the door to the chamber must be opened. This can result in a temperature swing in the middle of testing as ambient air floods the chamber.

OUR SOLUTION

The AVE3 Advanced Video Extensometer is designed to work through the optical quality glass on the front of the 3119-600 series environmental chambers. The AVE3 is a non-contacting video extensometer and can measure the strain through failure, eliminating the need to open the chamber door during testing, increasing operator safety and enabling accurate strain measurement throughout the test.