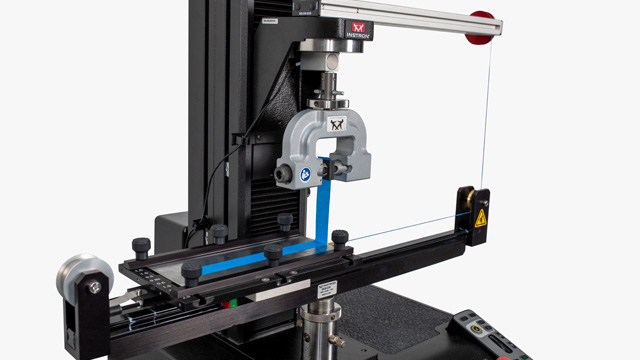

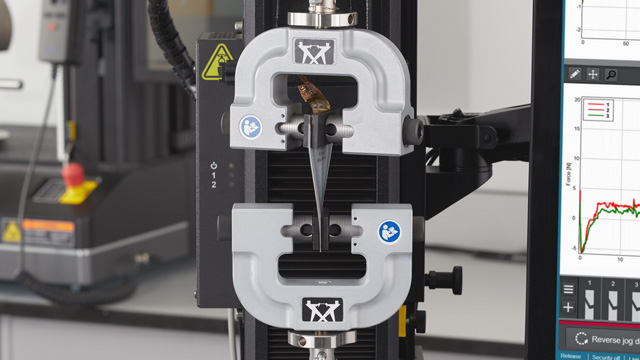

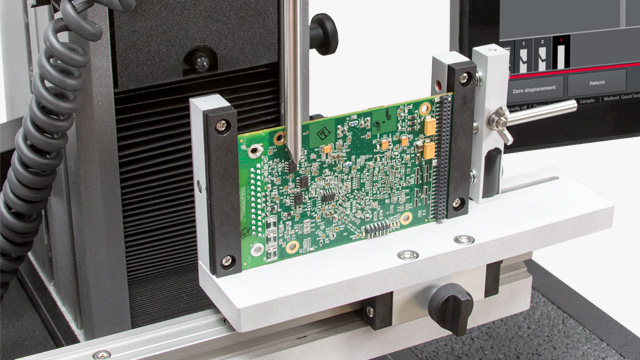

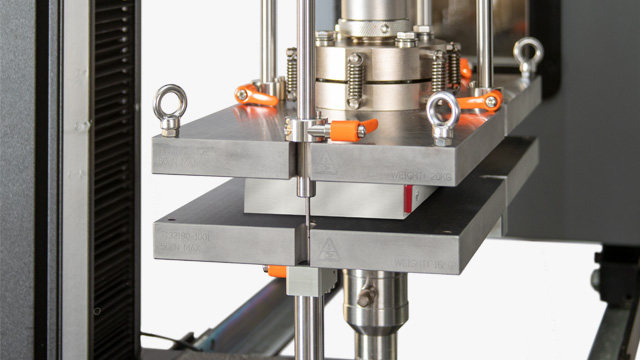

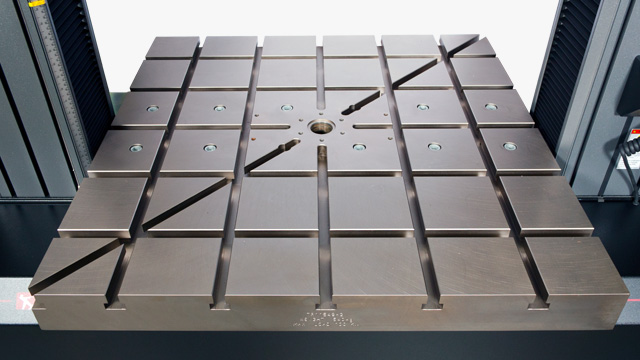

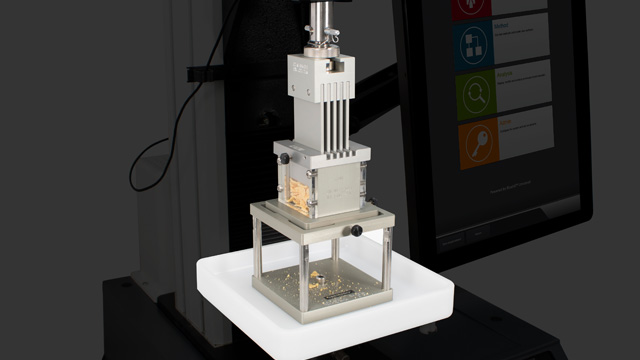

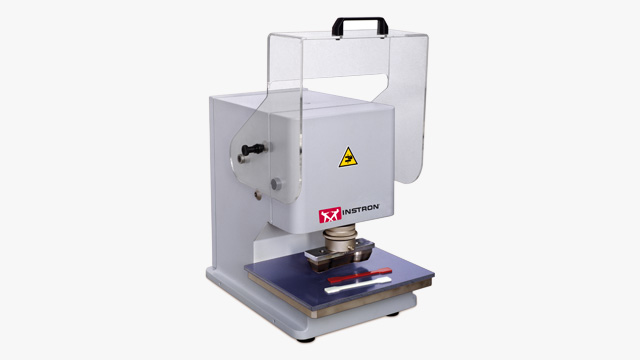

Testing Accessories

Instron has used its wealth of applications and engineering experience to produce the most extensive range of accessories for materials testing instruments in the industry. Made up of hundreds of grips, fixtures, load cells, and other accessories, our vast range of general purpose and application-focused accessories are designed to help you get the most from your materials testing system. Select a category below, view the interactive accessories catalog or request a PDF copy to get started.