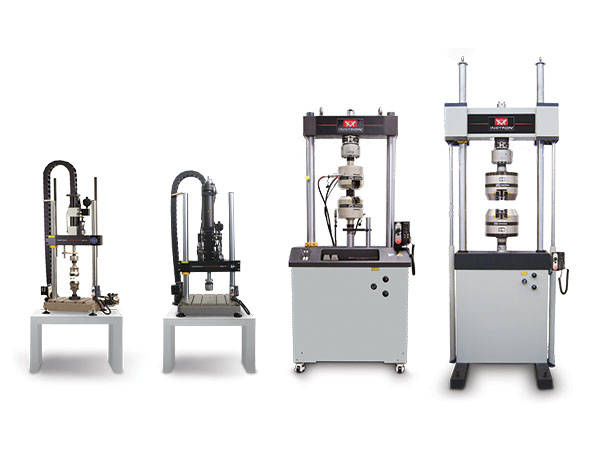

DYNAMIC AND FATIGUE TESTING SYSTEMS

Instron offers an extensive range of fully-integrated dynamic and fatigue testing systems from 1000 N up to 5000 kN. Incorporating servohydraulic, servo-electric and linear motor technologies, these test instruments cover a broad range of fatigue, dynamic, and static testing applications. These applications include high-cycle fatigue, low-cycle fatigue, thermo-mechanical fatigue, fracture mechanics, crack propagation and growth studies, fracture toughness, bi-axial, axial-torsional, multi-axial, high strain rate, quasi-static, creep, stress-relaxation, and other types of dynamic and static tests.

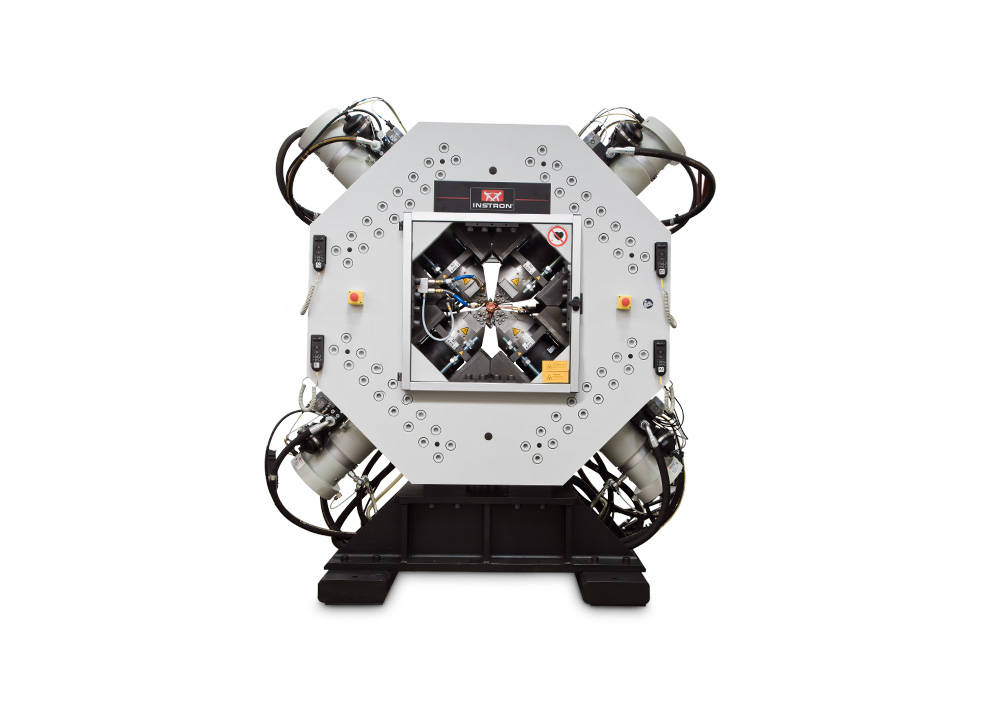

ElectroPuls 16-Station Testing Systems

ElectroPuls 16‑station fatigue fixture allows the simultaneous testing of up to 16 specimens, significantly reducing total test times and improving overall testing efficiency. This high‑capacity setup helps laboratories accelerate development cycles and deliver new products to market even sooner.

Out of Production Dynamic Systems

Systems that are no longer in production are provided with a comprehensive level of ongoing technical and replacement part support. View this section to understand the status of the product life cycle and consider which options exist to either upgrade or retrofit your existing system.