Over the past 20 years, the importance of occupant protection in the development of automobiles has greatly increased. Tighter legal requirements and consumer protection programs have led to significant innovations in the area of active and passive safety. Passive safety is mainly focused on the development of methods and guidelines that reduce the severity of injuries caused by accidents.

A wide range of new materials are being used to decrease the weight of vehicles and reduce emissions. Of these new materials continuous carbon fiber polymer composites offer great potential for producing lightweight structures, however, there are many barriers to their widespread adoption. Currently, the cost and process times of composites parts are significantly higher than those of traditional metal parts and they require new recycling techniques. Progress is being made with the development of lower cost carbon fibers and thermoplastic matrix materials that offer faster manufacturing processes and facilitate recycling.

Compression After Impact test (CAI) is used to define the damage resistance of composites after an Impact event. An impact on composite laminate panel may result in no visible external damage, but it may generate a dramatic reduction of compressive strength. The design of automotive parts using composite materials should consider the effects of impact on the material properties. These data can be obtained following dedicated standards (i.e. ASTM D7136M, ASTM D7136), using an Instron Drop Tower configured with CAI accessories.

In the automotive sector, development in chassis and body of vehicles is driven by two main aspects, safety, and lightweighting. As the body is the first point of impact during a car crash, modern designs have incorporated features such as crumple zone to absorb most of the initial impact, reducing the force that will reach the passengers. With this in mind, it is essential to understand material behavior under high strain rate, especially during development cycles of metals, alloys, and composites that may be used in chassis or body design. On the other hand, lightweighting provides better fuel economy for the car, decreases component wear and hence provide a much more competitive product overall. Therefore, characterizing how material properties change under high strain rate is important in order to find the optimum design maximizing safety and lightweighting.

Sheet Metal High Strain Rate Testing

The Challenge

When considering the crashworthiness of components, testing in high strain rates is essential. As investigated by numerous research, mechanical properties of materials differ drastically under quasi-static conditions and high strain rates. Therefore, accurate data on strain rate dependence of material behavior will provide more realistic computer simulation and evaluation of crashworthiness of structures, whether it is during the development of new alloys or testing automotive components.

Our Solution

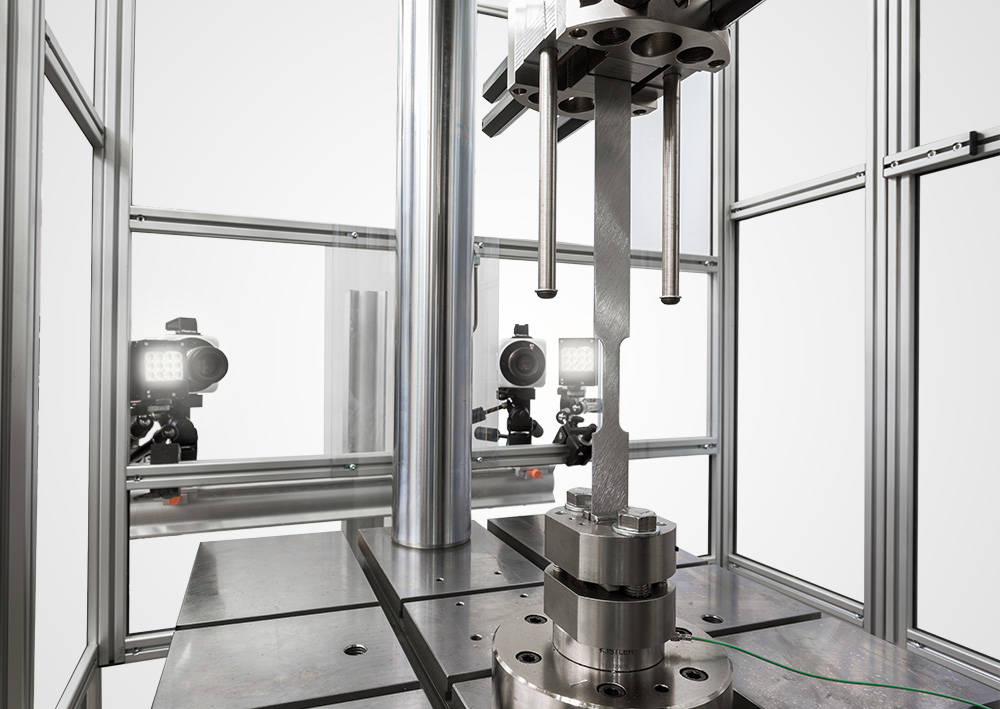

To meet the challenges of high strain rate testing, Instron has been the market leader in manufacturing high strain rate testing machines for over 20 years, advancing high strain rate research and testing capabilities on metals with suitable technologies. For testing metals and high-performance alloys, Instron offers a range of VHS systems that can perform tests that will be suited to your application up to a maximum test velocity of 25 m/s, which translates to testing conditions from quasi-static up to a strain rate of 1000/s. Instron also offers fast jaw or slack rod tensile gripping solutions to ensure gripping at test velocity and DIC integration that will provide non-contact strain measurement with the capacity for dedicated strain gauge channels.

Knowing the formability of metals is absolutely critical in the manufacture and development of automobiles, typical performance indicators for the formability properties are the plastic strain ratio (r-value) and strain hardening exponent (n-value). Bend testing is also vital in drawing conclusions about the forming behavior and the susceptibility to failure of metallic materials during the forming processes dominated by bending deformation but also during crash deformation.

Globally, there are increasing efforts to reduce the weight of automobiles, increasing fuel efficiency which aids in the reduction of emissions. Various grades of steel have been the predominant material used for manufacturing automobiles chassis' and body. A new generation of advanced high-strength steels (AHSS) are being developed and produced to maintain the automotive industry’s demand for steel.

Despite this, automotive manufacturers are now also working with aluminum producers to increase the percentage of aluminum used in the production of automobiles. Aluminum offers low density, excellent formability, corrosion resistance, and high strength.