Headliner Peel Testing

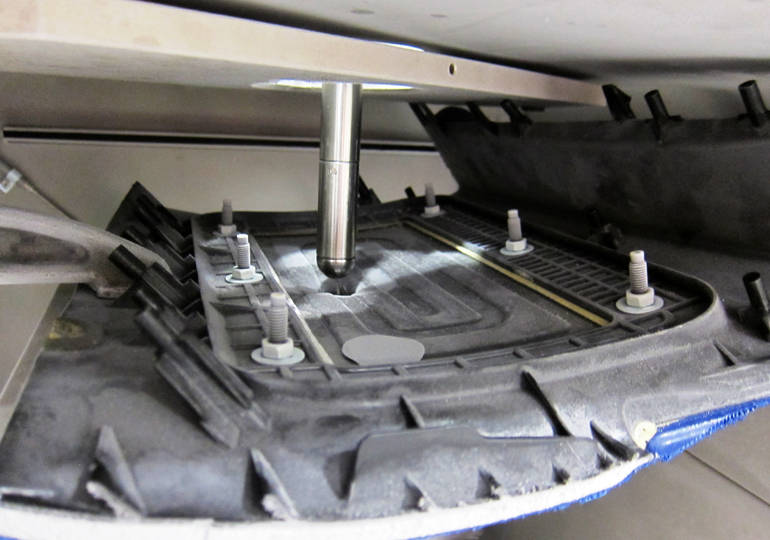

THE CHALLENGE

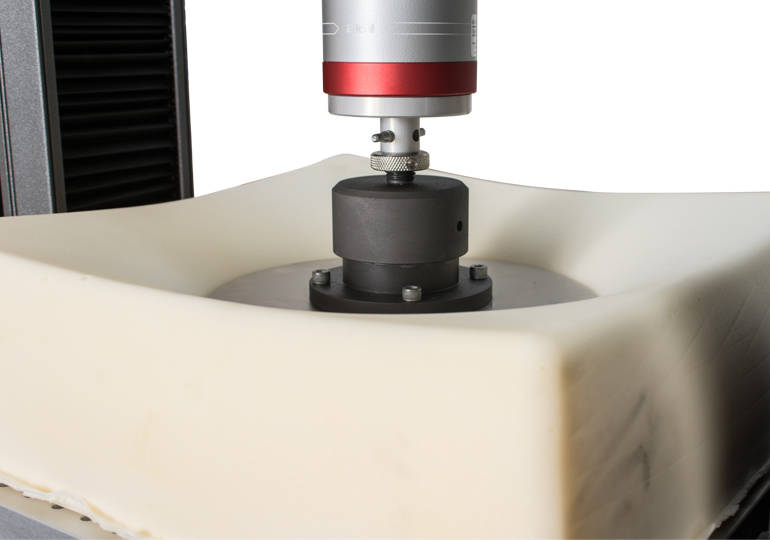

Some vehicle textiles have multiple layers or backings, and must be subjected to a peel test in order to determine if adhesion forces are appropriate.

Our Solution

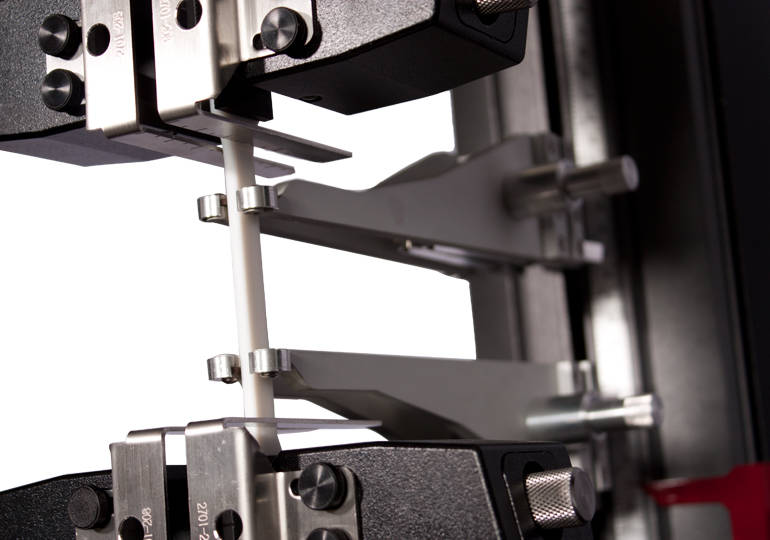

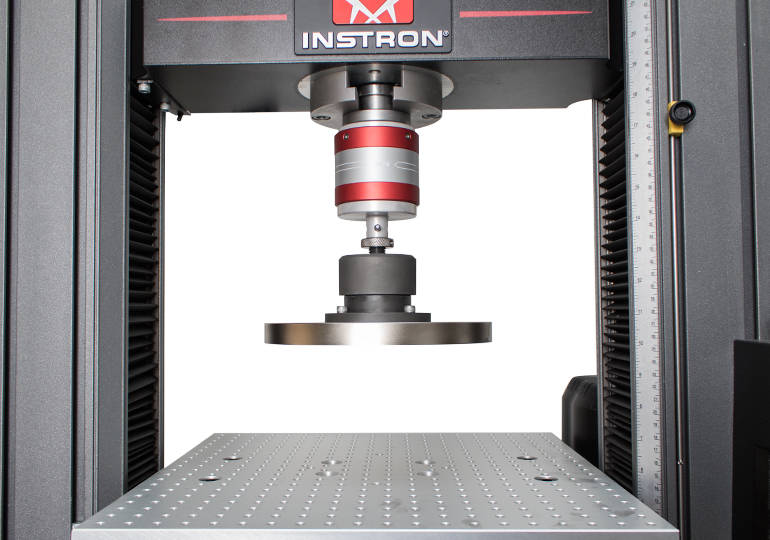

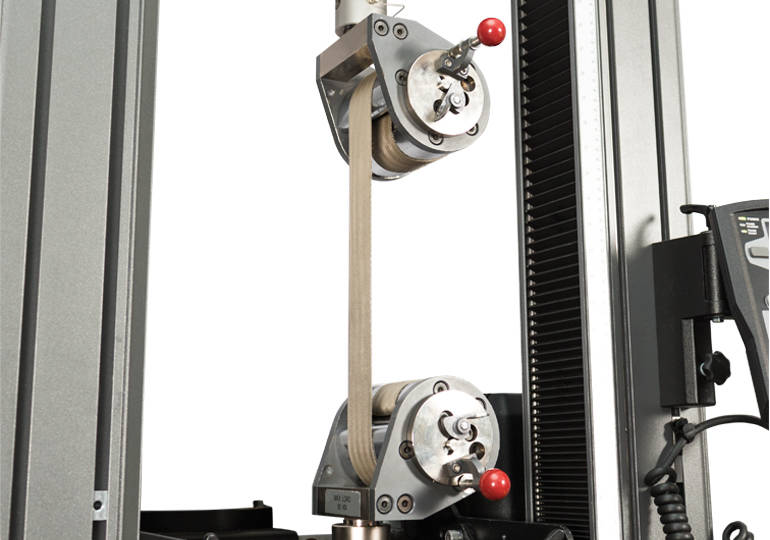

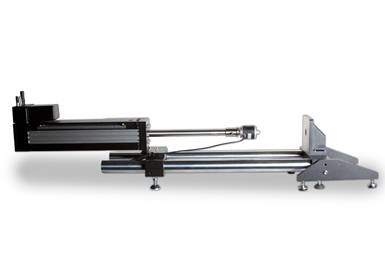

Instron® pneumatic side action grips are able to grip delicate foam specimens in order to perform T-peel tests. With a variety of quick-release jaw faces, these grips allow users to easily test a range of materials with a single system. The air pressure is also adjustable, allowing operators to fine tune the gripping pressure if needed.

Bluehill® Universal software contains a suite of calculations for peel testing, including industry standard calculations, such as first peak, average peel force over a given length, and even allows for custom calculations.