Syringe Testing to ISO 11040

Mechanical Testing of Prefilled Glass Syringes

ISO 11040 is a testing standard that addresses the design and functional properties of prefilled syringes. ISO 11040 is used primarily within the pharmaceutical industry and is critical for ensuring that syringes work properly in a clinical setting. ISO 11040 evaluations are performed throughout the manufacturing process to minimize any chance of defective equipment leaving the factory as failure of any subcomponent can have a major impact on either the physician or patient: an improper seal can cause oxidation of the drug and affect the shelf life of the product, while structural damage to the syringe barrel could lead to device failures. Note: Labs that manufacture syringes must be in compliance with 21 CFR Part 11.

NAVIGATING THE STANDARD

ISO 11040 is composed of 8 parts:

- Parts 1-3 refer to the subcomponents of cartridges used for local anesthetic in dental settings.

- Parts 4-6 refer to the subcomponents of prefilled syringe including glass barrels, plastic barrels, and plunger stoppers.

- Part 7 addresses the packaging systems typically used for pre-sterilized fill and finish applications. "Fill and finish" refers to the process of preparing the syringes for their end use, which is often a bottleneck in the supply chain.

- Part 8 outlines the test methods and evaluation criteria for the finished syringe rather than the individual subcomponents. These tests include durability of the syringe barrel, functional use of the devices (break loose and glide forces, needle penetration forces), and evaluation of the device closures and safety features. Many of the test methods outlines in part 4 and part 6 are analogous to those in part 8.

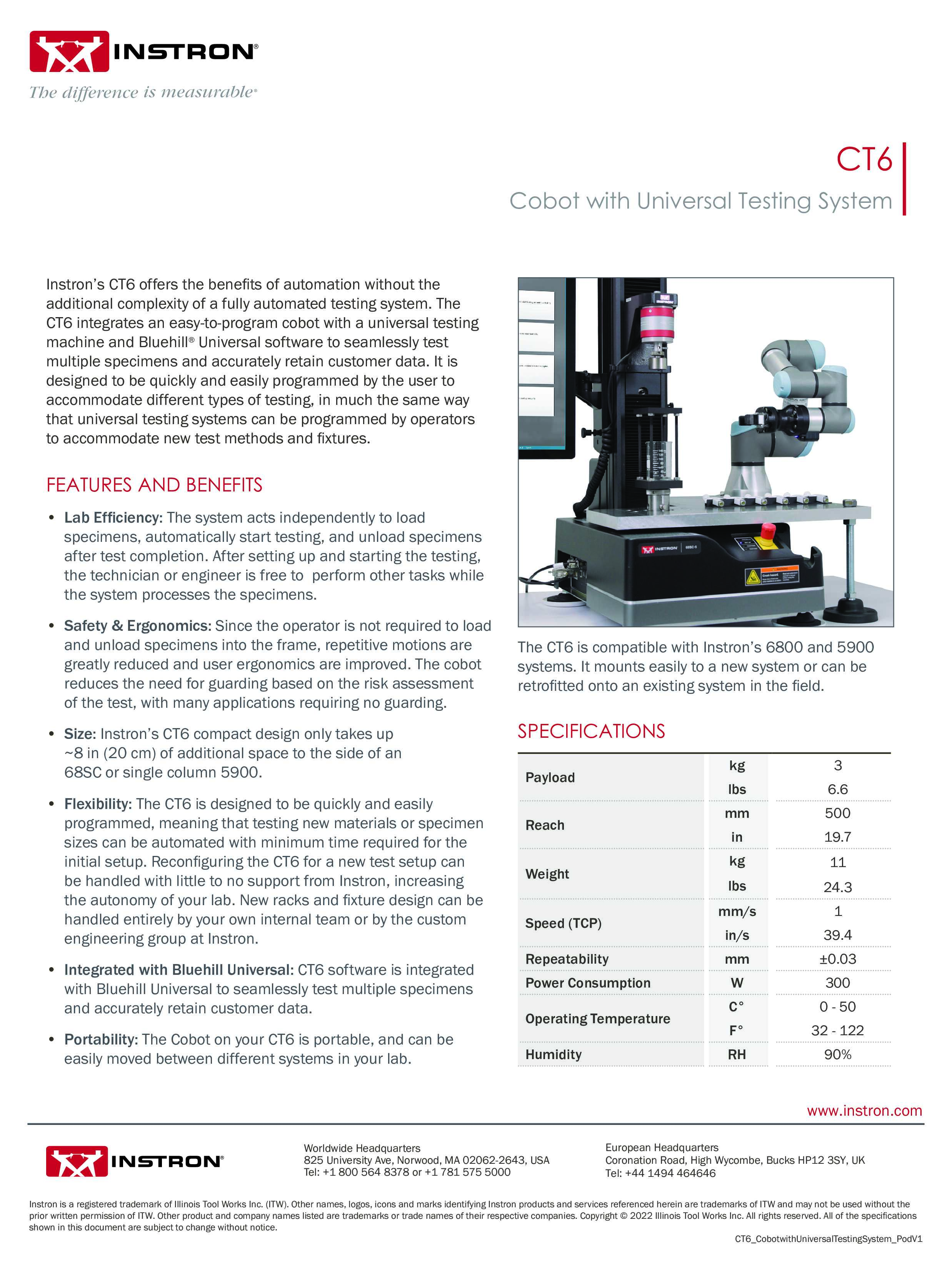

Materials Testing System

Testing to this single standard can require up to 12 unique test procedures, each needing different fixturing and system parameters. Maximizing test efficiency while ensuring operator safety can be a significant challenge. Instron recommends using our 68SC1 test frame with Bluehill Universal software along with fixturing appropriate to your specific needs. Some customers only test to specific methods and can make use of generic syringe fixturing, but for customers testing to multiple ISO 11040 methods, we recommend using a modular fixture to reduce setup time between procedures. Because of the dangers associated with breaking glass, we also highly recommend using integrated protective shields. Devise closure evaluation often requires biaxial testing capabilities to determine torques associated with screwing and unscrewing closure systems. In these cases we recommend that the 68SC1 system be augmented by Torsion Add-On 3.0, which enables a standard axial universal testing machine to perform biaxial testing.

| ISO 11040 Test Setup Options | |

|---|---|

| 6800 Series Universal Testing System | |

| Bluehill Universal Software | |

| 2527 Series Biaxial Load Cell | |

| Torsion Add-On 3.0 | |

| CP132121 Modular Test Fixture | |

AUTOMATION OPTIONS

Annex G.5 of ISO 11040 specifically assesses the removal torque of rigid tip caps used in conjunction with female luer lock connections. When used in conjunction with a torsion-enabled universal testing system, a cobot can be extremely beneficial for lab productivity - essentially functioning as a pick and place operation to reduce operator influence. The repeatability of automated specimen insertion is also ideal for improving device alignment, a significant contributor to data spread. Since prefilled syringes can come in a range of capacities, the sample racking can be customized to accommodate all potential device geometry, and the seamless integration with Bluehill Universal means test methods for new devices can be created quickly.

Tips and Tricks

- Though pre-filled syringes are primarily used within the pharmaceutical industry, these delivery systems can also be used with so called borderline products as well, which can include some non-medical chemicals like hyaluronic acid.

- Learn more about drug delivery and container testing.