Tensile Testing of Steel Cords

Steel cord is formed by twisting multiple strands of steel wires together to form a cord structure. This is often used as a reinforcement material in conveyor belts and radial tires for passenger cars, buses, or heavy equipment vehicles. Compared to other traditional reinforcement materials like nylon, steel cords possess superior mechanical properties, such as higher tensile strength and modulus and better heat resistance. When used as a reinforcement material in radial tires, it offers high road stability, improved steering response, and longer tire service life. Since some of the key performance indicators of tires are dependent on the reinforcing steel cord, it is important for an engineer to understand the properties of the tire cord and how it functions in a tire.

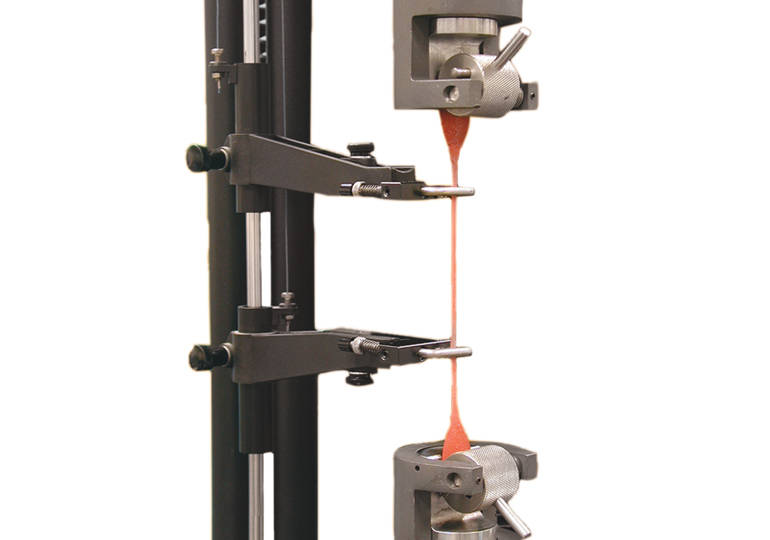

There are many challenges to account for when testing stranded wire. As stranded wire is not a consistent diameter, generally a nominal diameter is used (as defined in the product standard). As well as the irregularity of the surface, when a specimen is pulled in tension each strand will rotate. Therefore, if a clip-on extensometer is being used, it must be able to rotate. It is also necessary to have a long gauge length, so Instron offers a 600mm G.L. extensometer with 15 degrees of twist available. When stranded wire breaks, the energy released at failure is substantial, and the specimen ‘splays’ out. This may cause damage to extensometers, machine or even operators.

The challenges of testing to this standard are:

- Specimen gripping

- Strain measurement

- Safety

Instron's Solution:

- Instron provides side action grips with wire strand inserts that ensure optimum grip face engagement and clamping surface area.

- Instron’s E-series extensometers allow for a 600mm gauge length and specimen rotation, providing a robust strain-measurement solution.

- Debris shields are available in many shapes and sizes, and can be interlocked to ensure operators are not in danger at any time throughout testing.

It is important to review the pertinent testing standards in order to fully understand the test setup, procedure, and results requirements.

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

- ผลิตภัณฑ์

- 02/10/2020

- 1.93 MB

Bluehill Universal Brochure

Bluehill Universal is Instron’s advanced materials testing software, designed for intuitive touch interaction and streamlined workflows. It offers pre-loaded test methods, QuickTest for rapid setup, enhanced data exporting, and Instron Connect for direct service communication. Users of Bluehill 2 and Bluehill 3 can easily upgrade to the latest version for improved performance and usability

- ผลิตภัณฑ์

- 02/26/2017

- 3.76 MB