Materials Testing Machines

Materials testing machines come in a variety of different types and force capacities in order to perform specific types of testing. Despite this variety, all testing machines have a common set of features that enable them to test and adequately characterize materials, components, and finished products.

| Components of a Universal Testing Machine |

| Test Frame Test frames feature robust, precise guidance columns that ensure minimal specimen bending under load. High-quality test frames feature pre-loaded bearings, precision ball screws, an extra thick crosshead and base beam, and low-stretch drive belts to ensure superior performance and longevity. They are powered by maintenance-free brushless AC servomotors and a dual-belt system to provide synchronous movement of the ball screws, eliminating crosshead tilt and aiding system alignment. |

| Test Software All test systems require software in order to operate the machine and collect and interpret results data. Modern software should prioritize data security and feature a user-friendly interface and intuitive workflows. |

| Load Cell A load cell is a transducer that converts force into an electrical signal that can be measured. Load cells must be regularly calibrated in order to ensure their accuracy. They should be highly accurate over a wide range of measurements with high stiffness and resistance to offset loads. |

| Grips and Fixtures A wide variety of grips and fixtures are available to help secure the vast array of different material types and specimens that undergo testing on these machines. These fixtures range from tensile grips to compression platens, peel and flex fixtures, custom fixtures for testing biomedical and electronic components, as well as many others. |

Plastics are used for an unlimited number of applications, from packaging to biomedical, automotive, and electronics applications. Key properties evaluated during testing are tensile strength, yield strength, modulus, and elongation. Major plastics testing standards include ASTM D638, ASTM D790, ISO 8295, ISO 527, and The Definitive Guide to ISO 178 Flexure Testing for Plastics.

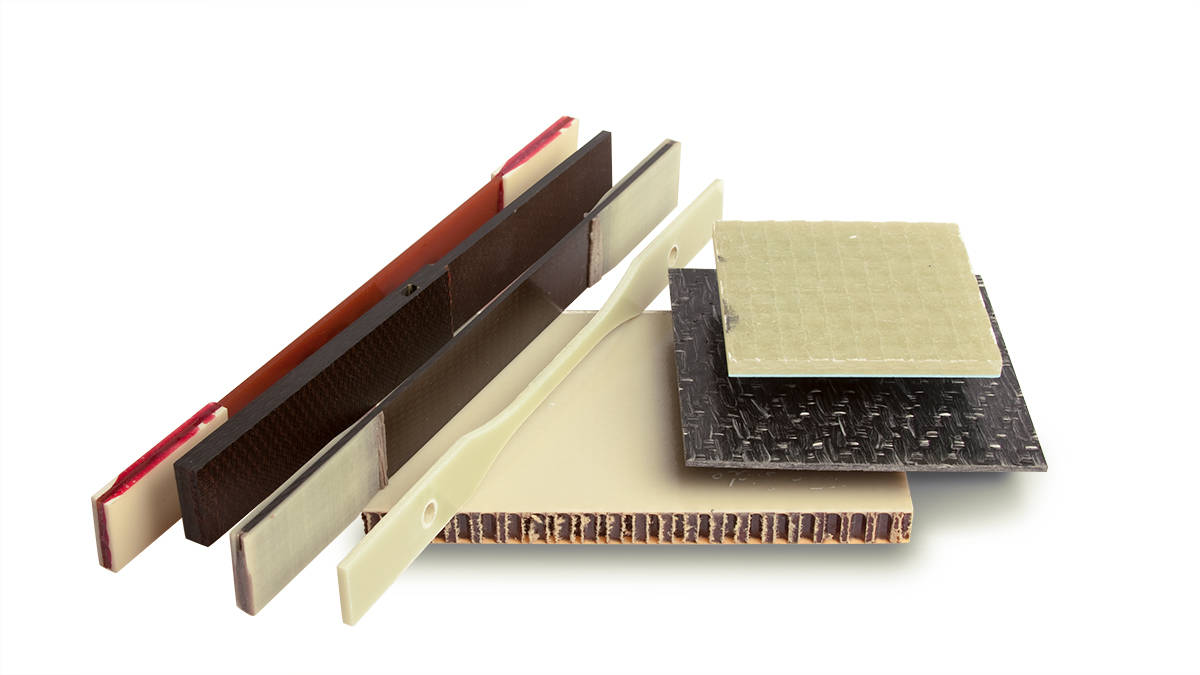

Composites are complex materials made from polymers reinforced with a fiber such as glass, aramid, or carbon. They are used extensively in applications such as aerospace and wind energy that demand high strength, lightweight materials. Key composites testing standards include ASTM D3039 and ISO 527-4. Important measurements include tensile strength, shear strength, yield strength, and fracture toughness.

Elastomers are high-elongation materials such as natural rubber, silicone, and polyurethanes that are used for making tires, medical devices, sealants, and many other products. Tensile strength, total elongation, and tensile stress at a given location are key properties. Major testing standards include ASTM D412, ASTM D642, and ISO 34.

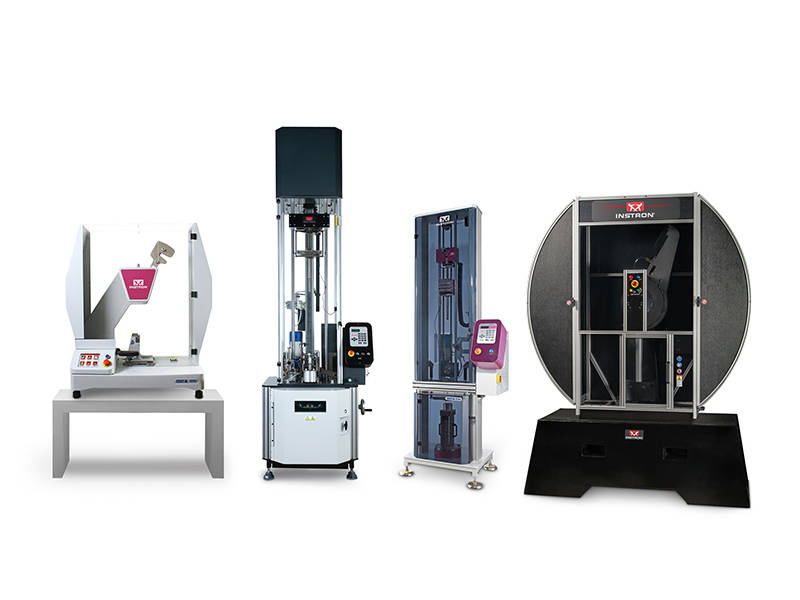

Products for Materials Testing

As the leading global manufacturer of testing equipment for the material and structural testing markets, Instron's product line includes systems for nearly every form of mechanical testing. Our large product portfolio allows technicians to evaluate materials ranging from biological tissue to advanced high-strength alloys by performing a variety of tests such as compression, cyclic, fatigue, impact, multi-axis, rheology, tensile, and torsion.

Choosing A Testing Partner

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

3400 Series Universal Testing Systems Brochure

Instron 3400 Series universal testing systems for tensile, compression, bend, and other material property tests.