Evaluation of Radial Forces from Embolic Filters

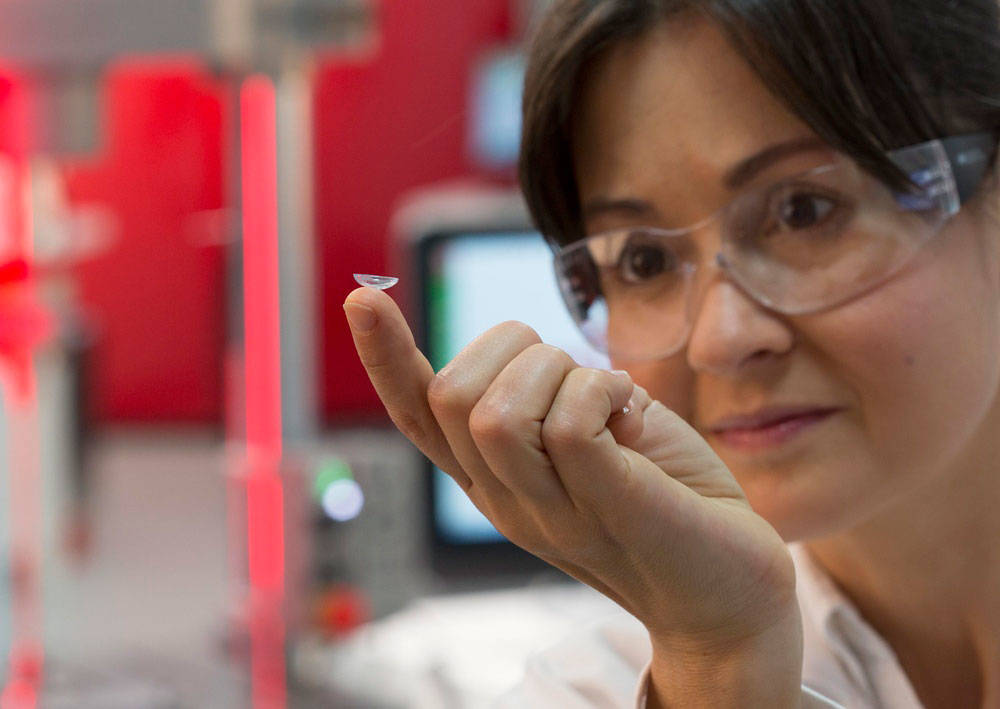

Embolic filters are used within a variety of interventional procedures to capture debris resulting from the deployment of a medical device, like a stent. The stent is used to open arterial paths that may be occluded by plaque. Upon placement of the stent, dislodged plaque (or embolic material) can potentially be responsible for heart attacks, strokes, kidney failure, or death. Firm placement of the embolic filter is a critical requirement for successful procedures.

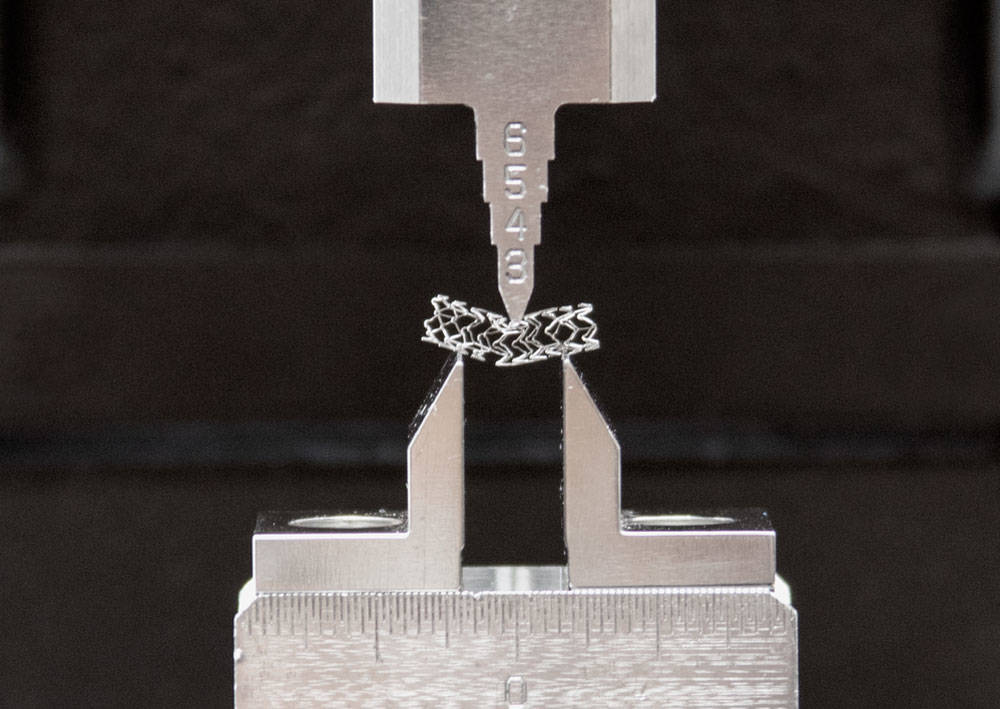

One of the most critical parameters for proper utilization of the filter is the radial forces it imparts on the arterial wall. In particular, the chronic radial force that the filter imparts over time helps to ensure that the device remains in place as intended. This fit ensures that all material is captured before heading further down the arterial pathways.

The RX575 system has the fidelity to measure the small radial expansion forces of the embolic filter. The unique segment design of the fixture results in small frictional forces, which ensures that your data will present clean results from the radial tests. The radial fixture mounts to electromechanical instruments, as well as into a fluid bath for accurate simulation of body temperatures. Additionally, the fixture provides the capability for tensile tests to evaluate resistance to tearing properties during deployment.

Bluehill® Software provides an interface to run tests, to evaluate the radial strength, and to generate standard reports that can be submitted for regulatory submissions.

3400 Series Universal Testing Systems Brochure

Instron 3400 Series universal testing systems for tensile, compression, bend, and other material property tests.

- Productos

- 06/27/2022

- 2.69 MB

6800 Series Premier Testing Systems Brochure

Instron 6800 Series Universal Testing Systems provide unparalleled accuracy and reliability. Built on a patent-pending Operator Protect system architecture with an all-new Smart-Close Air Kit and Collision Mitigation features, the 6800 Series makes materials testing simpler, smarter, and safer than ever before.

- Productos

- 02/10/2020

- 1.93 MB