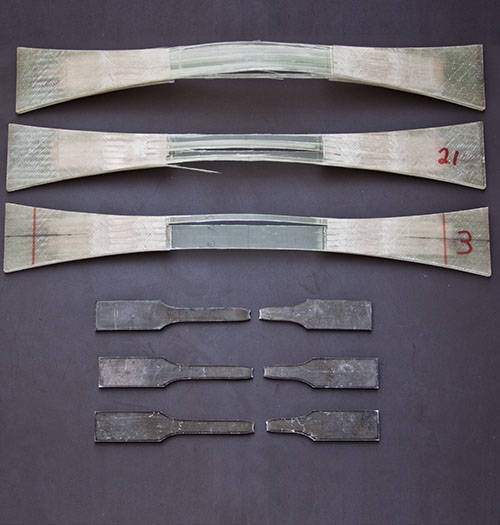

木材测试工装

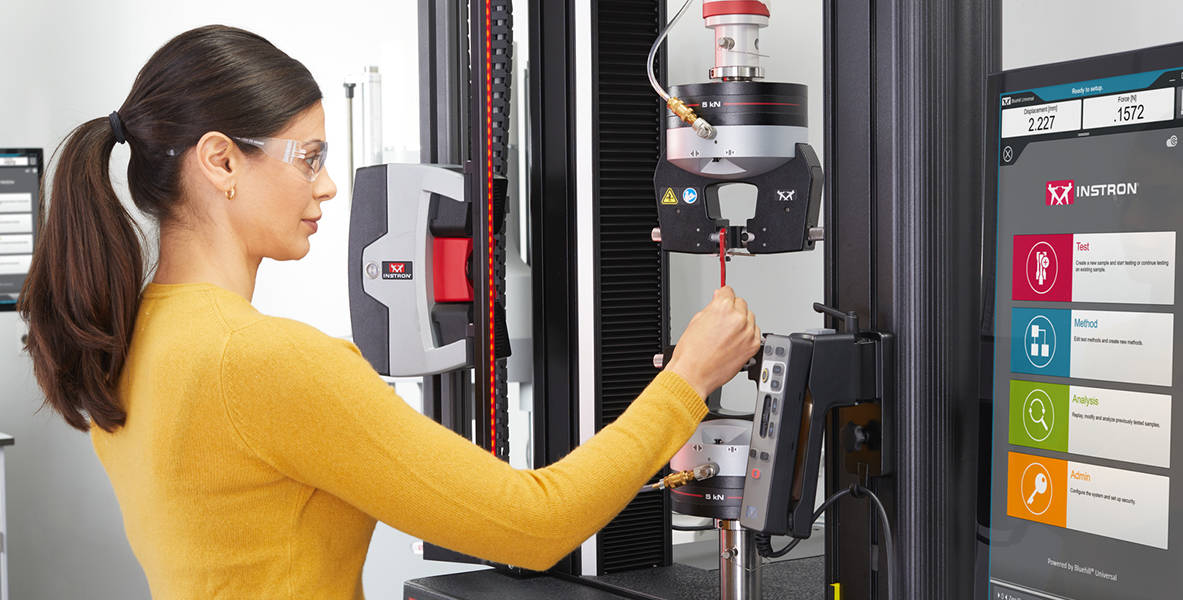

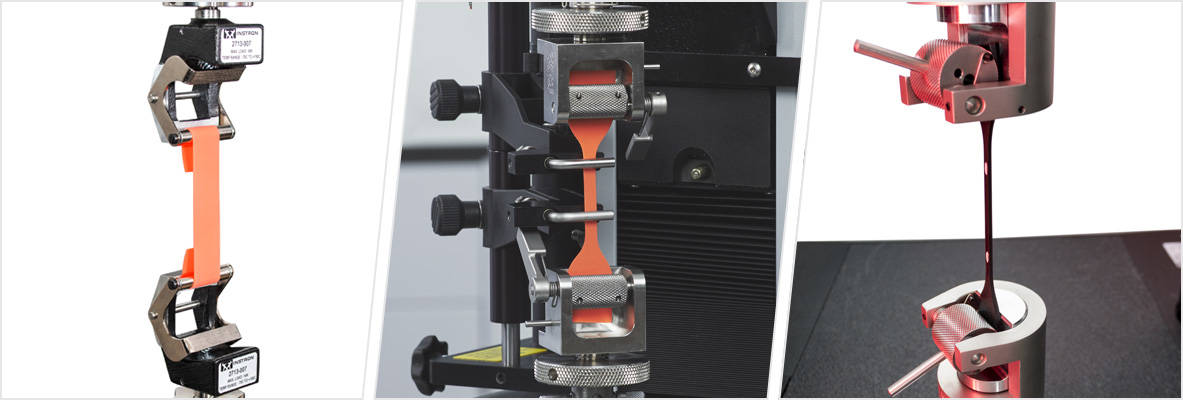

木材材料的特性分析需要在不同载荷条件下进行一系列测试,例如拉伸、压缩、剪切和弯曲。Instron 提供一系列高性能木材测试工装,符合相应的 ASTM、ISO、EN、JIS 和其他测试标准的要求。

木材材料的特性分析需要在不同载荷条件下进行一系列测试,例如拉伸、压缩、剪切和弯曲。Instron 提供一系列高性能木材测试工装,符合相应的 ASTM、ISO、EN、JIS 和其他测试标准的要求。

请您填写下表,我们将尽快与您联系。我们的在线留言答复时间一般为 1-2 个工作日,如您需要尽快答复,请致电 400 820 2006,谢谢。

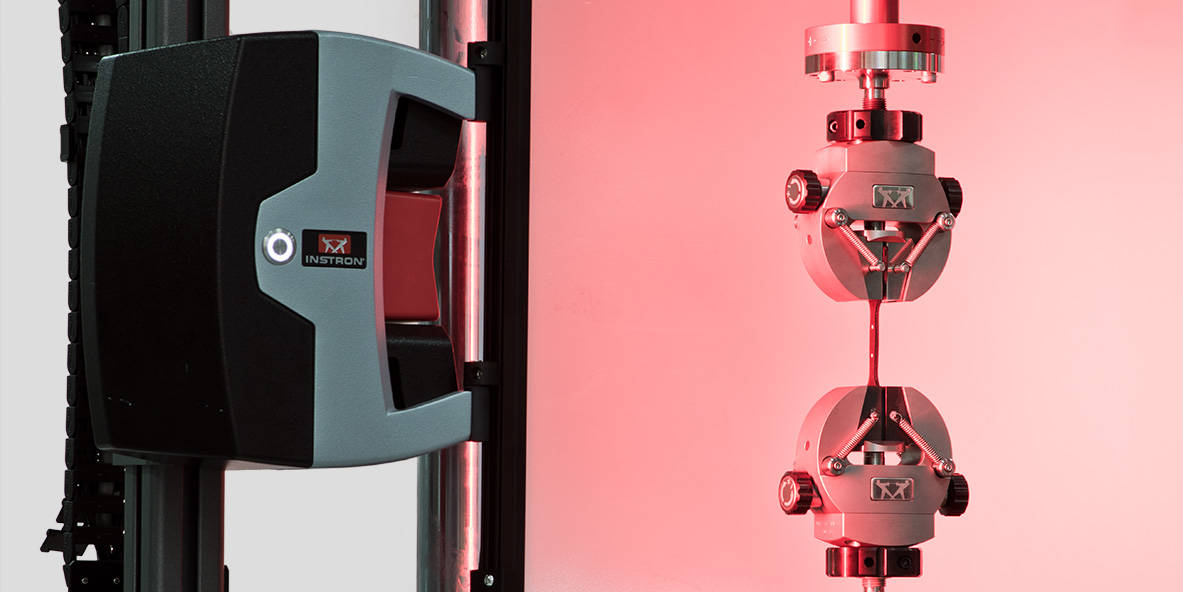

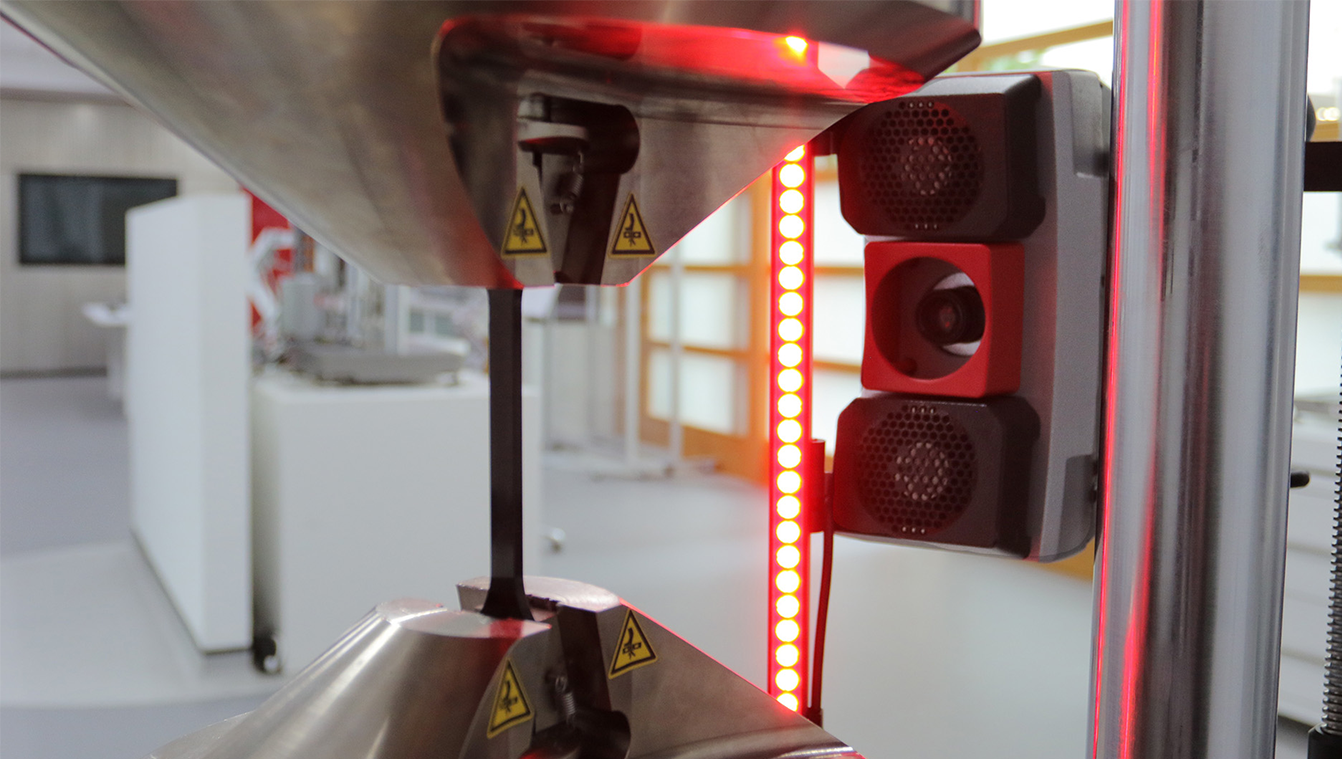

AVE3 可测量几乎所有应用场景下的弹性模量与断裂应变,包括平面及圆柱形试样的静态拉伸、弯曲和压缩试验。 在环境试验箱或流体浴槽中,可于常温或高低温条件下采集测量数据。无论您测试的是塑料、金属、复合材料、纺织品、薄膜、箔材、弹性体、纸张、零部件还是生物材料,AVE3 均能以卓越的灵活性满足不断变化的测试需求,并符合以下标准:

镜头根据您独特的测试设置进行配置,并在出厂时完成标定。光圈和焦距均被锁定,以消除操作人员的可能造成的任何影响。每个镜头均内置唯一识别编号,使试验系统能够通过磁吸安装自动识别设备编号。这种新的连接方法确保了镜头每次安装位置的可重复性。此外,AVE3 还采用简化标定板,在保持加载链完好无损的情况下直接夹在试样上,便于定期标定检查,确保您的设备始终处于最佳测试状态。

注:选择镜头时,请确保您了解最小和最大标距要求,以及您计划测试的试样范围的总延伸量。

借助全新 AVE3,您现在能够执行需要应变控制的测试,包括 ASTM E8 和 ISO 6892。AVE3 在精度和 500 Hz 数据采集率方面的进步,使您的试验系统能够对应变率的变化做出实时响应,从而帮助您快速、深入了解情况,确保测试结果具有可重复性和可比性,并严格符合国际测试标准的要求。

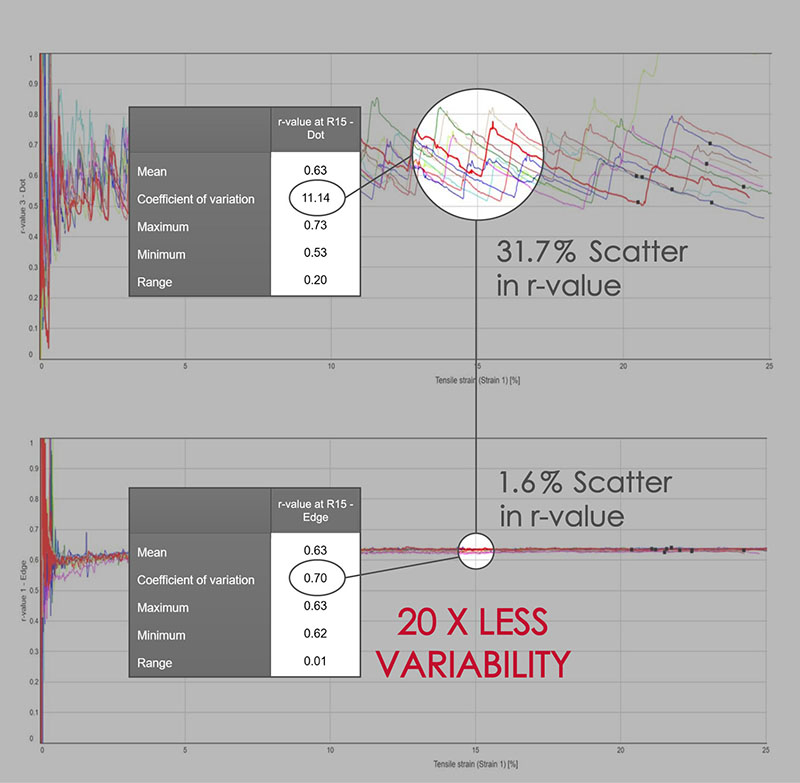

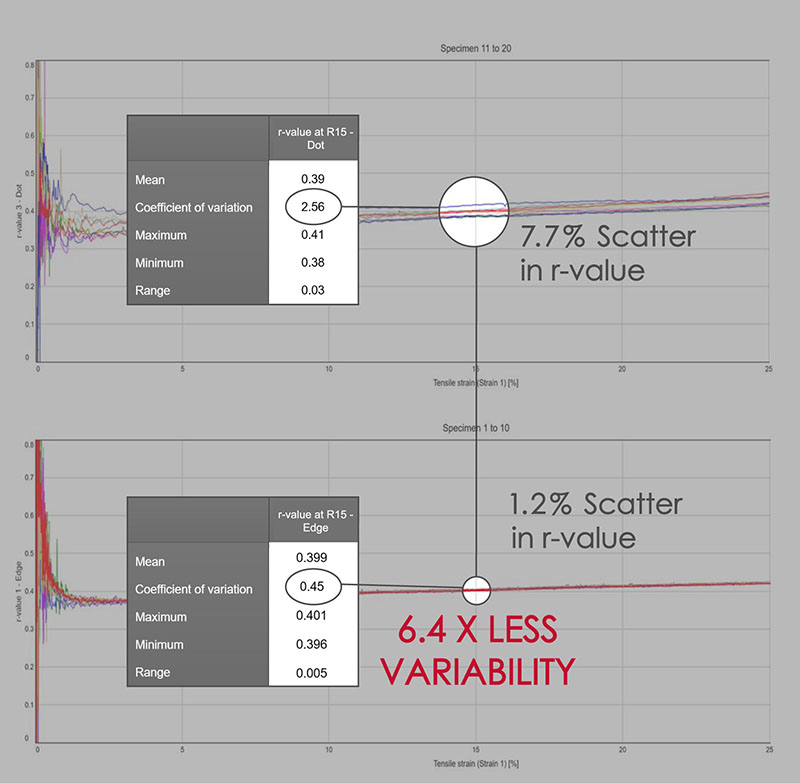

AverEdge32 是 AVE3 的一项可选高级功能,它利用边缘检测技术同时 测量试样标距长度上 32 个位置的横向应变。然后实时对这些数值进行平均, 得出平滑且可重复的横向应变值,这对于计算金属板材的 r 值至关重要。

数字图像相关(DIC)是一种光学技术,通过比较被测试样表面的图像来生成全场应变和位移图。生成的图像可用于直观显示被测试样整个二维表面的应变和位移。

英斯特朗的液压夹具泵专为大载荷试验提供精确可靠的夹持力而设计,载荷范围最高可达 600 kN。

These machines are developed to obtain specimens by punching, using hollow dies of different sizes and contours. Several hundreds of dies can be created by interchangeable socket punches with different profiles and size according to the standards and to the customer needs. Dies are made of steel with hand finished cutting edges and can be provided with ejector for easy removal of the specimen after punching.

Compact design of instrument for an easy and fast preparation

Manual and automatic models obtain specimens of different size and geometries for a wide range of plastics testing applications

High level of results repeatability and time saving test procedures

For Universal Testing Systems

Our standard furnaces, mounts, grips, and load string assemblies for universal testing systems allow for testing up to 1200°C in air. Our engineered solutions group is also able to develop solutions to meet higher temperature requirements and additional furnace dimensions.

1200°C Three-Zone Split Tube Furnace

This three-zone split tube furnace features a side entry extensometer port and is manufactured with a wire-wound element for maximum operation up to 1200°C (2200°F). The elements are uniquely formed to provide optimum temperature uniformity, ensuring conformance with testing standards such as ASTM E21, ISO 6892-2, EN10002-5,and EN2002-2. The top and bottom furnace endplates are durable, provide excellent insulation, and include a 20 mm (0.787 in) diameter hole for use with pull rods.

| Specifications | |||

| Specimen Temperature Range | 200 - 1050°C (392 - 1922°F) | ||

| Overall Heated Length | 300 mm (11.81 in) | ||

| Interior Diameter | 75 mm (2.95 in) | ||

Mounting brackets are used to securely attach the furnace to the test system.

| Specifications | |||

| Description | Catalog No. | ||

| Floor Model Standard Furnace Mounting A standard 3-knuckle design furnace mounting that allows for manual adjustments. | CP119938 | ||

| Floor Model Advanced Furnace Mounting The advanced mounting allows for quick and easy fine adjustments of the vertical position of the furnace as well as parallelism to the load string. | CP107737 | ||

Three-Zone Temperature Control Systems

Temperature control systems are designed for controlling the heat output of furnaces. The control systems can be configured to operate nearly any furnace with any one of several different thermocouples types. Three zone control systems are designed for heat-only furnaces with three separate zones of heating elements, and typically three different thermocouples to control those zones.

| Specifications | |||

| Description | Catalog No. | ||

| Type K Control System | 3119-960 | ||

| Type R/S Control System | 3119-962 | ||

| Stepdown Transformer The wall mount 3KVA stepdown transformer assembly provides the ability to operate the 120V, single phase Model TCS3203 3-zone furnace control system from 190/200/208/220V, 50/60Hz power sources. | W-C015-TRAN | ||

Quick-change adapters are typically used in hot tensile applications to provide simplified load train installation. They consist of a button-head washer that is threaded onto the room temperature end of a pull rod. The washer and pull rod are then inserted through a slot in the adapter body.

| Specifications | |||

| Force Capacity | Effective Length | Catalog No. | |

| 90 kN | 6.43 in | W-7556M4 | |

| 10 kN | 5.58 in | W-7556M2 | |

Threaded End Specimen Holders

Catalog No. W-7551-C

Threaded-end specimen holders made of Inconel 713-C rated for a maximum temperature of 1100 Deg. C (2000 Deg. F).

| Specifications | ||

| Specimen Thread Size | Catalog No. | |

| Metric M6 x 1.0 | W-7551-CM1 | |

| Metric M8 x 1.0 | W-7551-CM2 | |

| Metric M8 x 1.25 | W-7551-CM3 | |

| Metric M10 x 1.5 | W-7551-CM4 | |

| Metric M12 x 1.5 | W-7551-CM5 | |

| Metric M12 x 1.75 | W-7551-CM6 | |

| Metric M14 x 2.0 | W-7551-CM7 | |

| Metric M16 x 1.5 | W-7551-CM8 | |

| Metric M16 x 2.0 | W-7551-CM9 | |

| Metric M18 x 2.5 | W-7551-CM10 | |

| Metric M19 x 1.5 | W-7551-CM11 | |

| US Customary 10-24 | W-7551-CU1 | |

| US Customary 10-32 | W-7551-CU2 | |

| US Customary 1/4-20 | W-7551-CU3 | |

| US Customary 1/4-28 | W-7551-CU4 | |

| US Customary 5/16-24 | W-7551-CU5 | |

| US Customary 5/16-18 | W-7551-CU6 | |

| US Customary 3/8-16 | W-7551-CU7 | |

| US Customary 3/8-24 | W-7551-CU8 | |

| US Customary 7/16-14 | W-7551-CU9 | |

| US Customary 1/2-13 | W-7551-CU10 | |

| US Customary 5/8-11 | W-7551-CU11 | |

| US Customary 3/4-10 (Type R3f) | W-7551-CU12 | |

Pull Rods

High temperature pull rods made of made of Inconel 713-C for strength and resistance to corrosion and oxidation. Both ends are threaded 0.75-10m-RH and are compatible with a range of grips, adapters, and specimen holders.

Rated for 9070 kgs (20,000 lbs) load up to 760°C (1400°F) and 1360 kgs (3000 lbs) load at a maximum temperature of 1100°C (2000°F).

| Specifications | |||

| Pull Rod Length | Force Capacity | Catalog No. | |

| 273 mm (10.75 in) | 90 / 26.7 kN | W-7546-C | |

| 330 mm (13.00 in) | 90 / 26.7 kN | W-7547-C | |

High Temperature Tension Wedge Grips

Catalog No. W-7554

One set (2) wedge grip specimen holders made of Hastelloy X. Holders designed for tension-only loading and may be equipped to accept flat specimens from 1.13 mm to 3.18 mm thick (0.005 in to 0.125 in) by 12.7 mm to 22.225 mm wide (0.5 in to 0.875 in). Design of holders requires drilling of holes in specimen end tabs for initial loading and jaw alignment. Centering pin diameter 4.1148 mm (0.162 in). Holders are 70mm (2.75 in) long by 38mm (1.375 in) diameter contain 0.75-10f-RH thread for attachment to pull rods. Jaw inserts ordered separately, selected based on thicknesses of specimens to be tested. See W-7554-A1, -A3, and -A4 below for available inserts and corresponding thickness ranges.

| Specifications | |||

| Specimen Diameter | Pin 4.1148 mm (Pin 0.162 in) | ||

| Specimen Thickness | 1.13 - 3.18 mm (0.005 - 0.125 in) | ||

| Specimen Width | 12.700 - 22.225 mm (0.500 - 0.875 in) | ||

| Temperature Rating | 926°C (1700°F) | ||

High Temperature Wedge Jaw Inserts

One set (two pairs) of high temperature wedge jaw inserts for use with the W-7554 high temperature tension wedge grips.

| Specifications | |||

| Type | Specimen Thickness | Temperature Rating | Catalog No. |

| Smooth-Faced | 0.13 to 1.0 mm (0.005 to 0.040 in) | 926°C (1700°F) | W-7554-A1 |

| Serrated-Faced | 1.0 to 2.0 mm (0.040 to 0.078 in) | 926°C (1700°F) | W-7554-A3 |

| Serrated-Faced | 2.0 to 3.18 mm (0.078 to 0.125 in) | W-7554-A4 | |

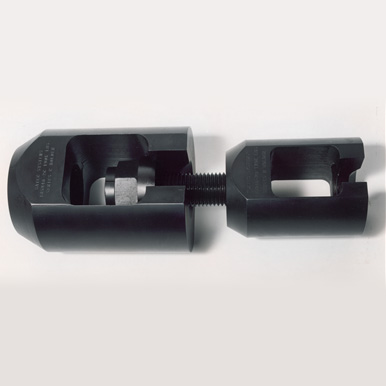

Pin and Clevis Holders

Pin and clevis specimen holders are designed for flat specimens that have a hole in each end. The specimen fits into the slot of the holder and is secured by the pin.

Note: Using a specimen that is smaller (thinner) than the slot width specified for a given set of holders can result in misalignment of the specimen.

| Specifications | |||

| Material | Iconel 713-C | ||

| Temperature Rating | 1100°C (2000°F) | ||

| Upper and Lower Fittings | US Customary 3/4 in-10 (Type R3f) | ||

| Coupling Length | 69.9 mm (2.75 in) | ||

| Coupling Diameter | 28.6 mm (1.125 in) | ||

| Available Sizes | |

| Size | Catalog No. |

| 1 mm slot, 3 mm pin | CP112249 |

| 2 mm slot, 3 mm pin | CP112250 |

| 3 mm slot, 4 mm pin | CP112251 |

| 4 mm slot, 4 mm pin | CP112252 |

| 6 mm slot, 6 mm pin | CP112253 |

| 10 mm slot, 10 mm pin | CP112255 |

用于弯曲、挠曲和断裂韧性粘合测试

弯曲工装可用于进行多种弯曲试验和断裂韧性粘合试验,包括测定弯曲模量、弯曲强度和弯曲屈服强度。 易于安装的三点夹具可以通过可选的转换套件进行修改,以提供四点弯曲转换。下砧可调,以适应不同跨度的样品。样品的挠度可以通过横梁位移来测量,或者为了更精确的测量,您可以使用带有夹式引伸计的中跨直接测量柱塞。

工作原理

试样由两个具有确定半径的精密加工砧支撑。力施加在中心(3 点)或中心任一侧的确定距离处(4 点)。支撑梁以公制单位纵向分级,用于准确定位砧,等间距到中心线。

特点

应用范围

加载类型:静态弯曲、循环弯曲试验

试样材料:塑料、金属、合金、复合材料、陶瓷和其他材料

试样形状:条、棒、组件

常用标准: ASTM D790、ISO 178

| 规格 | |

|---|---|

| 目录号 | 2810-400 |

| 最大容量 | 5 kN (1125 lbf, 500 kgf) |

| 温度范围 | -100 °C 至 350 °C (-148 °F 至 660 °F) |

| 可调跨距距离 | 10 - 200 mm (0.39 - 7.87 in) |

| 查看完整规格 | 下载宣传册 |

Today's testing laboratories and manufacturers have a wide variety of material and component testing needs. To meet these varying requirements, Instron has several accessories designed to help interface with external equipment and measuring devices.

2810-500/505

操作原理适合静态和动态弯曲试验,该弯曲工装可配置为三点或四点(需加装2810-505)装置。试样放置在两个下支撑滚轴上,通过单个加载滚轴或是四点弯曲配置时的两个上加载滚轴,对试样中心施加载荷。

该工装具有18–148 mm(0.7–5.82 in)的可变跨距,适用于各种试样长度。下部和上部均装有一个法兰附件,可与所有新型ElectroPuls®试验机(除了E1000)直接兼容。

试样放置于两个下支撑上,上支撑滚轴用于在试样上施加反向的力。这允许进行高周弯曲疲劳试验。

应用范围

如需了解更多信息,请下载资料

访问ElectroPuls网页

Revolutionary Strain Control

Revolutionary Strain Control

If you want to protect your strain measurement device from damaging shock loads then contact us to discuss your non-contacting strain application today.

销连接转销连接转接头用于连接接口比载荷传感器或机架底座更大或更小的夹具和工装。

| 适用型号 | |||

| 接口 1 | 接口 2 | 连接方式 | 目录编号 |

| 公头 - OO 型 (6 mm 外径接头,带有 2.5 mm 直径销子) |

母头 - O 型 (12 mm 内径接头,带有 6 mm 直径销子) |

刚性 | 2501-350 |

| 公头 - OO 型 (6 mm 外径接头,带有 2.5 mm 直径销子) |

母头 - C 型 (5/8 in内径接头,带有 1/4 in 直径销子) |

刚性 | S1-13807 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

母头 - B 型 (1/2 in 内径接头,带有 3/16 in 直径销子) |

刚性 | 2501-134 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

母头 - C 型 (5/8 in 内径接头,带有 1/4 in 直径销子) |

刚性 | 2501-133 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

刚性 | 2501-093 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

母头 - O 型 (12 mm 内径接头,带有 6 mm 直径销子) |

刚性 | 2501-346 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

母头 - B 型 (1/2 in 内径接头,带有 3/16 in 直径销子) |

刚性 | 2501-119 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

母头 - C 型 (5/8 in 内径接头,带有 1/4 in 直径销子) |

刚性 | 2501-120 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

母头 - 1 型 (34 mm 内径接头,带有 16 mm 直径销子) |

刚性 | 2501-338 |

销连接转销连接转接头用于连接比载荷传感器或机架底座具有更大或更小接头的夹具和工装。柔性转接头用于某些测试应用的试样对中。

| 适用型号 | |||

| 接口 1 | 接口 2 | 连接方式 | 目录编号 |

| 公头 - OO 型 (6 mm 外径接头,带有 2.5 mm 直径销子) |

母头 - B 型 (1/2 in 内径接头,带有 3/16 in 直径销子) |

柔性 | 2501-115 |

| 公头 - OO 型 (6 mm 外径接头,带有 2.5 mm 直径销子) |

母头 - C 型 (5/8 in 内径接头,带有 1/4 in 直径销子) |

柔性 | 2501-157 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

阴头 - O 型 (12 mm 内径接头,带有 6 mm 直径销子) |

柔性 | 2501-348 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

母头 - B 型 (1/2 in 内径接头,带有 3/16 in 直径销子) |

柔性 | 2501-109 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

母头 - C 型 (5/8 in 内径接头,带有 1/4 in 直径销子) |

柔性 | 2501-094 |

| 公头 - O 型 (12 mm 外径接头,带有 6 mm 直径销子) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

柔性 | 2501-091 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

柔性 | 2501-356 |

| 公头 - 1 型 (34 mm 外径接头,带有 16 mm 直径销子) |

母头 - C 型 (5/8 in 内径接头,带有 1/4 in 直径销子) |

柔性 | 2501-170 |

| 公头 - 1 型 (34 mm 外径接头,带有 16 mm 直径销子) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

柔性 | 2501-090 |

在落地式系统上,当力传感器或机架是螺纹接口时,销连接转螺纹转接头可用于连接相关的夹具和工装。

| 适用型号 | |||

| 接口 1 | 接口 2 | 连接方式 | 目录编号 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

公头 - I 型 (M30x2 右旋螺纹) |

刚性 | 2501-173 |

| 公头 - D 型 (1.25 in 外径接头,带有 1/2 in 直径销子) |

公头 - II 型 (M48x2 右旋螺纹) |

刚性 | 2501-172 |

| 公头 - 1 型 (34 mm 外径接头,带有 16 mm 直径销子) |

母头 - O 型 (12 mm 内径接头,带有 6 mm 直径销子) |

刚性 | 2501-159 |

| 公头 - 1 型 (34 mm 外径接头,带有 16 mm 直径销子) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

刚性 | 2501-092 |

| 公头 - 1 型 (34 mm 外径接头,带有 16 mm 直径销子) |

公头 - I 型 (M30x2 右旋螺纹) |

刚性 | 2501-073 |

| 公头 - 1 型 (34 mm 外径接头,带有 16 mm 直径销子) |

公头 - II 型 (M48x2 右旋螺纹) |

刚性 | 2501-171 |

| 公头 - I 型 (M30x2 左旋螺纹) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

刚性 | 8005-061 |

| 公头 - II 型 (M48x2 左旋螺纹) |

母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

刚性 | 8005-062 |

螺纹转接头通常用于夹具和工装以实现高载荷测试。大多数液压载荷链、超过 100 kN 的载荷链,以及带有螺纹底座和载荷传感器连接的系统,都需要螺纹转接头。

| 适用型号 | |||

| 接口 1 | 接口 2 | 连接方式 | 目录编号 |

| 公头 - II 型 (M48x2 左旋螺纹) |

母头 - 1.5 in -12 右旋螺纹 | 刚性 | 2501-206 |

| 公头 - II 型 (M48x2 左旋螺纹) |

母头 - I 型 (M30x2 左旋螺纹) |

刚性 | 2501-205 |

| 公头 - II 型 (M48x2 左旋螺纹) |

母头 - 2 in -12 右旋螺纹 | 刚性 | 8005-022 |

| 公头 - I 型 (M30x2 左旋螺纹) |

公头 - I 型 (M30x2 右旋螺纹) |

刚性 | 8005-041 |

| 公头 - I 型 (M30x2 左旋螺纹) |

公头 - II 型 (M48x2 右旋螺纹) |

刚性 | 8005-045 |

| 公头 - II 型 (M48x2 左旋螺纹) |

公头 - I 型 (M30x2 右旋螺纹) |

刚性 | 8005-046 |

| 公头 - II 型 (M48x2 左旋螺纹) |

公头 - II 型 (M48x2 右旋螺纹) |

刚性 | 8005-042 |

| 公头 - IIA 型 (M72x3 左旋螺纹) |

公头 - IIA 型 (M72x3 右旋螺纹) |

刚性 | 8005-043 |

设备底座转接头通常用于将夹具或工装连接到设备上。在载荷范围为 10 kN 及以下的设备上,使用带螺丝通孔的销连接接头。在载荷范围为 30 kN、50 kN 和 100 kN 的设备上,使用带销连接的法兰适配器。对于载荷容量超过 100 kN 的设备,请参阅“螺纹转接头”部分。

| 适用型号 | |||

| 接口 1 | 接口 2 | 连接方式 | 目录编号 |

| 6 x M10 螺栓分布圆 | 母头 - D 型 (1.25 in 内径接头,带有 1/2 in 直径销子) |

刚性 | 2501-113 |

| 6 x M10 螺栓分布圆 | 母头 - II 型 (M48x2 左旋螺纹) |

刚性 | 2501-148 |

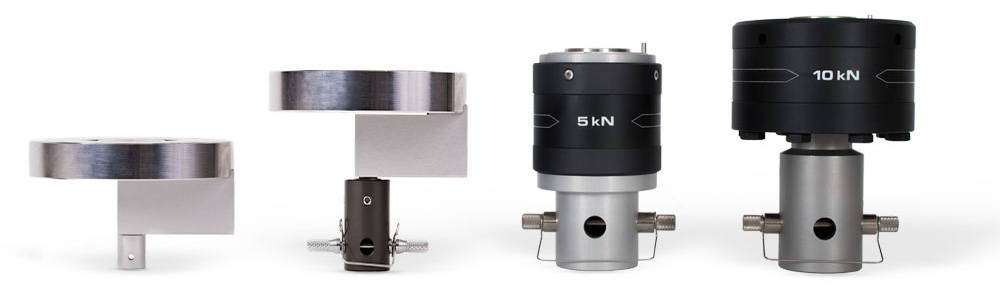

力传感器快接头使高达50kN的载荷传感器更易安装在横梁上。接头的一部分安装在横梁上,另一部分安装在载荷传感器上,使载荷传感器能够独立牢固地悬挂在横梁下,轻松拧紧螺栓完成安装。另配有载荷传感器转接头,可搭配多种载荷传感器使用。

| 适用型号 | |

| 描述 | 目录编号 |

| 用于 5900 或 6800 台式机到 2580、2530 和 2525 系列载荷传感器的全套套件 (包含横梁接头和一个载荷传感器接头) |

2501-212 |

| 适用于 500 N - 5 kN 2580 载荷传感器的快接头 | 2501-213 |

| 适用于 10 kN - 50 kN 2580 载荷传感器的快接头 | 2501-214 |

| 适用于 5 N - 5 kN 2530 载荷传感器的接头 | 2501-215 |

搭接载荷传感器转接头使系统的主载荷传感器在不拆卸的情况下安装小力值传感器。

| 适用型号 | ||||

| 兼容的主载荷传感器连接方式 | 兼容的次级载荷传感器 | 目录编号 | ||

| D 型 | 500 N 到 5 kN 用于安装 2580 系列载荷传感器。 | 2501-208 | ||

| D 型 | 5 N 到 5 kN 用于安装 2530 系列载荷传感器。 | 2501-210 | ||

| D 型 | 10 kN 到 50 kN 用于安装 2580 系列载荷传感器。 | 2501-209 | ||

| II 型 (M48) | 500 N 到 50 kN 2580 系列,500 N 至 50 kN(M10 或 M16 安装螺栓) 2530 系列,500 N 至 50 kN(M10 或 M16 安装螺栓) 2525 系列,50 kN 或以下 2519 系列,10 N 至 5 kN(M6 或 M10 安装螺栓) 2518 系列,50 kN 或以下 |

2501-227 | ||

| IIA 型(M72) | 500 N 至 50 kN 2580 系列,500 N 至 50 kN(M10 或 M16 安装螺栓) 2530 系列,500 N 至 50 kN(M10 或 M16 安装螺栓) 2525 系列 – 500 N 至 50 kN 2519 系列,10 N 至 5 kN(M6 或 M10 安装螺栓) |

2501-228 | ||

搭接载荷链转接头使不拆卸大载荷夹具的情况下,同时安装其他工装。

| 适用型号 | ||||

| 主夹具 | 提供的连接方式 | 目录编号 | ||

| 100 kN 液压楔形夹具(目录编号 2743-401) | Df 型(紧凑型) | 2501-258 | ||

| 100 kN 液压楔形夹具(目录编号 2743-401) | Df 型 | 2501-260 | ||

| 300 kN 液压楔形夹具(目录编号 2742-501) | II 型(M48) | 2501-255 | ||

| 300 kN 液压楔形夹具(目录编号 2742-501) | Df 型 | 2501-256 | ||

| 600 kN 液压楔形夹具(目录编号 2743-601) | IIA 型(M72) | 2501-259 此转接头只能用于压缩测试。 | ||

| 100 kN 精密手动楔形夹具(目录编号 2716-028) 250 kN 精密手动楔形夹具(目录编号 2716-030) |

Df 型 | 2501-700 | ||

| 100 kN 精密手动楔形夹具(目录编号 2716-028) 250 kN 精密手动楔形夹具(目录编号 2716-030) |

II 型(M48) | 2501-702 | ||

贯通式传感器快接头可将 2580 系列传感器安装到传统 Instron 万能试验系统,以及升级改造至 6800 试验系统的设备上。这些转接头可直接穿过横梁安装,适用于最大载荷范围为 100 kN 的台式和落地式试验系统。

| 适用型号 | ||||

| 机架兼容性 | 传感器兼容性 | 最大间距 | 目录编号 | |

| 4464、4465、4466、5564、5565、5566 | 2580 系列 (500 N - 10 kN) |

153 mm | 2501-290 | |

| 4467、4469、5567、5569 | 2580 系列 (500 N - 10 kN) |

165 mm | 2501-291 | |

| 4481、5581 | 2580-50kN (50 kN) |

133 mm | 2501-291 | |

| 4482、5582 | 2580-100kN (100 kN) |

111 mm | 2501-292 | |

当同轴度对某一测试应用非常重要时,万向球面拉伸接头 (USTA) 套件可提供独特的球面移动,进行少量补偿。这些螺纹转接头用于将拉伸工装安装到载荷传感器或机架底座上,或用于次级载荷链连接。

| 适用型号 | ||||

| 载荷范围 | 端部 1 机器接口 | 端部 2 附件接口 | 连接方式 | 目录编号 |

| 300 kN | IIm 型 (M48x2m LH) |

300 kN 载荷:R4m 型(M36x4) 100 kN 载荷:R3f 型(0.75-10) |

一端球面 一端刚性 |

W-5551-A |

| 300 kN 缩短 |

IIm 型 (M48x2m LH) |

载荷范围:R4m 型(M36x4) 100 kN 载荷范围:R3f 型(0.75-10) |

一端球面 一端刚性 |

W-5551-G |

| 300 kN | IIm 型 (M48x2m LH) |

300 kN 载荷范围:R4m 型(M36x4) 100 kN 载荷范围:R3f 型(0.75-10) |

双球面 | W-5551-B |

| 100 kN | Dm 型 (1.25 in 接头) |

载荷范围:R4m 型(M36x4 RH) 100 kN 载荷范围:R3f 型(0.75 in -10 RH) |

一端球面 一端刚性 |

W-5551-H |

| 300 kN 螺纹转接头轴衬套件 | R4f 型(M36x4f) | 刚性 | W-5551-D | |

| 600 kN | IIAm 型 (M72x3m LH) |

600 kN 载荷范围:IIm 型(M48x2m) 100 kN 载荷范围:R3f 型(0.75-10)螺纹 |

一端球面 一端刚性 |

W-5552-A |

| 600 kN | IIAm 型 (M72x3m LH) |

600 kN 载荷范围:IIm 型(M48x2m) 100 kN 载荷范围:R3f 型(0.75-10)螺纹 |

双球面 | W-5552-B |

| 400 kN | IIm 型 (M48x2m LH) |

400 kN 载荷范围:IIm 型(M48x2m) 100 kN 载荷范围:R3f 型(0.75-10)螺纹 |

一端球面 一端刚性 |

W-5552-E |

| 400 kN | IIm 型 (M48x2m LH) |

400 kN 载荷范围:IIm 型(M48x2m) 100 kN 载荷范围:R3f 型(0.75-10)螺纹 |

双球面 | W-5552-F |

| 600 kN 螺纹转接头轴衬套件 | IIf 型(M48x2f) | 刚性 | W-5552-G | |

适用于多种材料和试样类型的多功能夹持解决方案

气动平推夹具是夹取各种材料和试样的有效解决方案,包括纤维、导线、薄片、箔材、薄膜、纺织品、塑料、弹性体和组件。可重复的夹持力和操作速度使气动夹具成为各种测试应用的理想选择。此外,2712-04x 和 2712-05x 夹具还有许多增强功能,包括夹面防护罩、超快夹面更换和可选配的试样对中装置,进一步提高了易用性、可重复性和操作安全性。

50 N - 10 kN 受力能力

针对高温和低温测试要求,温度额定气动夹具为在温控环境中夹持各种材料提供便利。

气动夹具通过双杠杆臂夹持试样,由内置在夹具主体中的气缸驱动。夹持力可通过调节输入气压进行控制,即便试样在夹持区域发生收缩,夹持力仍能保持恒定,试样在试验过程中不会打滑。气动夹具可通过脚踏开关或安装在夹具上的气阀(大多数型号)进行操作,相较于手动平推夹具,操作更为快捷简便。

| 载荷范围 | 目录编号 |

|---|---|

| 50 N | 2712-051 |

| 250 N | 2712-052 |

| 1 kN | 2712-041 |

| 2 kN | 2712-042 |

| 5 kN | 2712-045 |

| 10 kN | 2712-046 |

保护操作人员免受夹伤风险

夹面防护罩

保护手指免受夹面之间的夹伤危险(专利申请中)。

可调式气流控制阀

可调式气流控制阀可用于减慢夹面闭合速度,以防止事故发生。

可调节开口

1、2、5 和 10 kN 型号的夹口面开口可调,可根据试样厚度进行设置。

无需任何工具即可轻松更换夹具和夹面

![]()

独特的锁紧螺母设计

专为轻松舒适的手动拧紧设计,以消除反向间隙。螺纹间距较小,也更容易施加所需的预紧力。

速释空气软管

可旋转连接设计可实现整洁的软管布置。快速连接功能使空气供应的断开操作快速简便。

旨在提高测试量和可重复性

对中装置

可选的试样对中装置可帮助操作员将试样装入夹具中心,从而提高重复性。

导线对中

夹面罩上的凹槽使导线测试更快更容易。

自对中设计

无需调整即可轻松保持载荷的轴向性,不受试样厚度变化的影响。

可偏移夹面

可偏移夹面可用于 5 KN 和 10 KN 夹具,允许测试不规则试样或部件(如搭接剪切)。

精密试样装夹器

可用于 250 N 夹具,这种可选配装置改进了薄膜和箔材测试的校准和设置过程,减少测试结果的变异性,同时提升人体工学设计与安全性。

试样夹持装置

可选配的试样夹持装置允许操作人员在测试空间外用手指关闭夹具。

多种夹面

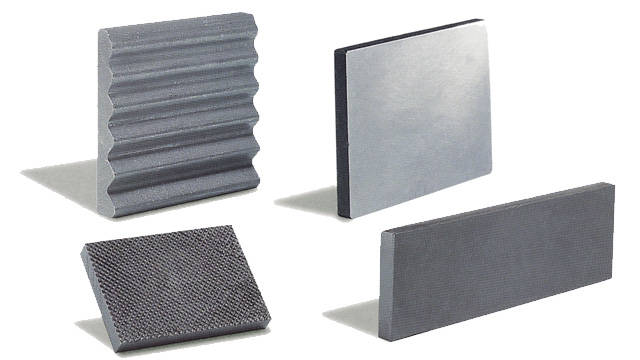

有橡胶涂层、锯齿状、光面、制动衬片 (HFC)、线接触式、波形轮廓和 V 型锯齿状。

用于测量高弹性材料中的应变

长行程 (XL) 伸长计设计用于单立柱和双立柱万能测试系统,可用于测量最大 30 英寸或 750 毫米的试样伸长量。XL 可以直接夹在试样上,方便快捷。它可以调节到 0.5 英寸到 5 英寸或 10 毫米到 200 毫米的增量量规长度。

运行原理

高伸长率拉伸计可直接夹在试样上,方便快捷。它可以根据 0.5 英寸到 5 英寸,或 10 毫米到 200 毫米的增量量规长度进行调整。XL 可容纳高达 10 英寸的夹钳位移,其特殊设计允许在不损坏拉伸计或以其他方式中断测试程序的情况下对样品进行断裂测试。XL 拉伸计基于一对精心平衡的夹钳组件,通过连接电缆驱动一个电位计。两个夹具均可自由移动,但任何分离或差动的增加都会使传感器前进。上下试样夹具分别进行平衡,并在带直线轴承的抛光研磨轴上进行导向,因此拉伸计的重量不会施加到试样上。

功能和优点

| 可用机型 | ||

|---|---|---|

| 目录编号 | 兼容框架 | 满刻度行程 |

| 2603-084 | 单立柱 | 250 毫米 |

| 2603-086(超长行程) | 单立柱 | 750 毫米 |

| 2603-080 | 双柱 | 250 毫米 |

| 2603-085(超长行程) | 双立柱 | 750 毫米 |

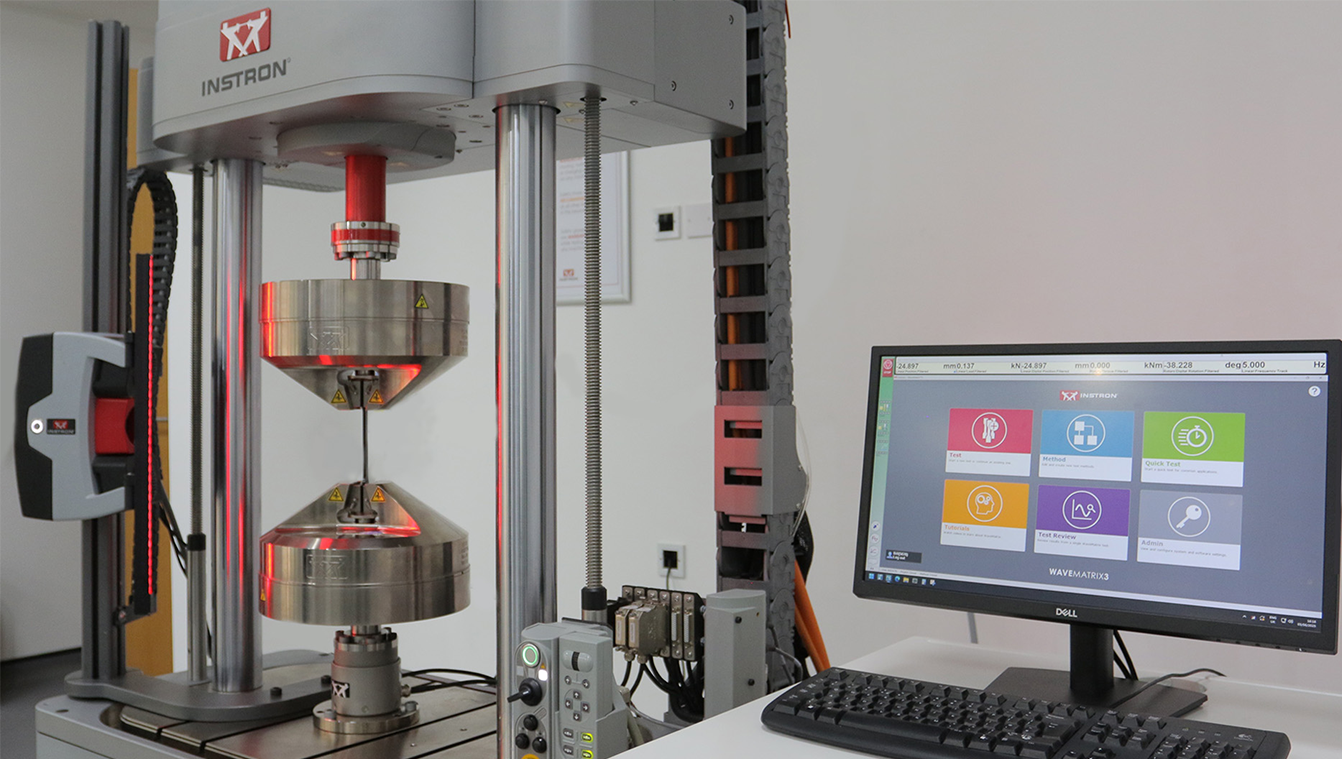

用于金属和复合材料的静态和动态测试

先进液压楔形夹具是一款多功能夹具,可用于静态和动态材料测试应用——动态测试力容量高达 500 kN,静态测试力容量高达 600 kN。 该夹具非常适合金属和复合材料测试,其可互换的夹具钳口可容纳板材或圆棒试样,并且夹具设计可在试样上保持恒定的夹持力,无论施加的测试力如何。 只要有充足的液压供应处于活动并连接状态,夹具就会施加这种受控的夹持力。

工作原理

每个夹具独立运行,外部液压供应提供压力以打开和关闭夹具。 当施加夹持压力时,试样与夹面的相对垂直位置保持不变,以避免夹持过程中试样产生负载。 一旦夹具钳口接触试样,液压就会在夹具头上产生垂直力。 由于该设计会自动补偿试样厚度变化,夹持力将保持恒定。

应用范围

添加试样对中装置(型号 CP135054),以确保您的试样对中一致。 该装置兼容我们先进液压楔形夹具的 2743-401、2742-501 和 2742-601 版本。

用于静态应变测量

英斯特朗的静态轴向夹式引伸计是一种快速且简捷的应变测量解决方案,适用于塑料、金属材料和复合材料等各种材料。我们数十年的应变测量经验帮助我们优化了这些装置的设计,包括:轻量级坚固交叉撑设计,可消除物理变形导致的误差;内置式保护,可减少装置过度延长造成的损坏;以及经过专门设计的装置臂,只需最小的作用力即可保持附着在试样上,从而最大限度地减少测试期间的刀口滑移。所有的引伸计均符合 ASTM E83 和 ISO 9513 标准,并随附显示每个单元在其出厂校准时的性能表现的校准证书。

2630-100 系列

工作原理

2630 系列引伸计可以进行准确且一致的安装或放置,并且标距长度闭锁装置会在附加后自动释放,从而确保运行的速度和可靠性。这种独特的“锥形闩锁”机构还克服了在开始测试前必须移除销钉或夹子的问题,或在引伸计意外锁定在标距长度时进行测试的问题。

功能与优点

应用范围

| 可用型号 | ||

|---|---|---|

| 目录编号 | 标距长度(公制) | 行程(轴向) |

| 2630-120 | 8 mm | ±50% |

| 2630-101 | 10 mm | ±10% |

| 2630-102 | 10 mm | ±50% |

| 2630-105 | 25 mm | ±10% |

| 2630-106 | 25 mm | +50% |

| 2630-107 | 25 mm | +100% |

| 2630-111 | 50 mm | ±10% |

| 2630-112 | 50 mm | +50% |

| 2630-113 | 50 mm | +100% |

| 2630-123 | 75 mm | +10% |

| 2630-117 | 80 mm | +10% |

| 2630-118 | 80 mm | +50% |

| 2630-119 | 100 mm | +50% |

| 目录编号 | 标距长度(美国惯例) | 行程(轴向) |

| 2630-121 | 0.3 英寸 | ±50% |

| 2630-103 | 0.5 英寸 | ±10% |

| 2630-104 | 0.5 英寸 | ±50% |

| 2630-108 | 1.0 英寸 | ±10% |

| 2630-109 | 1.0 英寸 | +50% |

| 2630-110 | 1.0 英寸 | +100% |

| 2630-114 | 2.0 英寸 | ±10% |

| 2630-115 | 2.0 英寸 | +50% |

| 2630-116 | 2.0 英寸 | +100% |

W-6280 系列

工作原理

这款长标距长度的夹式引伸计采用独特的可拆分式设计,不但可以降低试样断裂过程中发生损坏的几率,还有助于快速连接装备(包括在内)在试样上实现轻松安装。由于其机架尺寸较大,W-6280 系列引伸计需要双手操作才能将仪器安装到试样上,所以这些引伸计仍然依靠销钉来设定标距长度。

应用范围

| 可用型号 | ||

|---|---|---|

| 目录编号 | 标距长度(公制) | 行程百分比(轴向) |

| W-6280-200 | 200 mm | +12.5% |

| W-6280-250 | 250 mm | +10% |

| 目录编号 | 标距长度(美国惯例) | 行程百分比(轴向) |

| W-6280-8 | 8 英寸 | +12.5% |

Lever Action Grips and O-Ring Type

Fibers and filaments tend to be relatively thin materials compared to most, but within these types of materials there can be a wide range of thicknesses and tensile strengths that determines the appropriate gripping method. To properly hold onto these materials, Instron offers two types of grips: a lever action style and an O-ring type.

LEVER ACTION GRIPS

Catalog no. 2711-006

The Lever Action Grips provide the ideal means to hold single fiber specimens. The grips are simple, lightweight, and symmetrical in design.

Principle of Operation

Lever Action Grips are generally used for the thicker range of fiber filament specimens. These grips have an adjustable clamping force, self-aligning hard rubber coated faces, and provide ease of operation similar to a clothes pin. An adapter is provided to use the lower grip in the vertical or horizontal orientation to ease specimen insertion.

Application Range

| Specifications | |

|---|---|

| Capacity | 5 N |

| Specimen Diameter | 2.5 mm |

| Temperature Range | -10 °C to 100 °C |

| Upper and Lower Fittings | Type Om (12 mm connection with 6 mm clevis pin) |

| Misc. | Includes a Type A (hook) for the upper grip |

The O-Ring type of grip is designed to hold very small diameter fiber specimens during tension testing. The rubber v-groove provides a gradually increased frictional hold on the specimen and helps reduce grip face pinching and subsequent specimen jaw breaks. Special considerations are built into the design, where the U-shaped bend provides sufficient area for specimen loading.

Principle of Operation

The O-Ring fiber grip utilizes two rubber o-rings sandwiched between two knurled wheels. These wheels thread on a stud and compress the o-rings to achieve desired gripping force on the specimen.

Application Range

| Specifications | |

|---|---|

| Capacity | 0.825 N |

| Specimen Diameter | 1 to 25 microns |

| Temperature Range | -10 °C to 100 °C |

| Upper and Lower Fittings | Type Om (12 mm connection with 6 mm clevis pin) |

| Misc. | Includes a Type A (hook) for the upper grip |

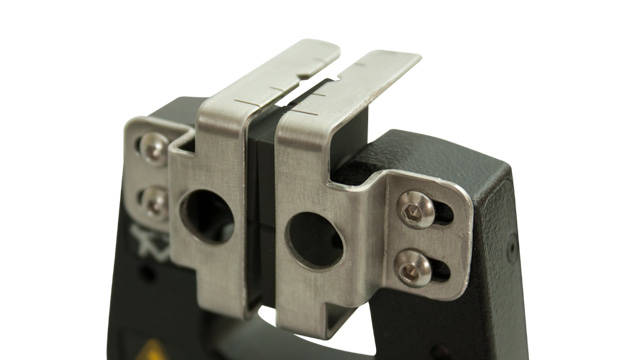

Featuring adjustable clamping pressure and quick-change jaw faces, these grips can be adapted to test a wide variety of specimens.

The grips can also be positioned at 0, 30, and 90 degrees, making them fully compatible with our non-contacting video extensometer products.

The precision specimen loader improves alignment and the setup process for testing thin films and foils, resulting in reduced variation in test results and improved safety and ergonomics. Available for our 250 N pneumatic side action tensile grips (catalog no. 2712-052), this device uses a detachable alignment clip and linear rail to guide the specimens into the grips. The precision specimen loader is available in multiple sizes to accommodate a wide range of specimen dimensions.

For more information on the importance of specimen alignment for tensile testing of thin films and foils, read our white paper that covers the results of experiments designed to determine the impact specimen alignment has on results.

This extensometer can be attached to round and flat specimens to perform tensile, compression, and cyclic tests in environmental chambers up to 600°C with no cooling required. A quick attach kit for mounting on specimens is included. The device has a low operating force that prevents it from affecting the test.

| Specifications | |

| Gauge Length | 25 mm |

| % Travel (Axial) | +50% / - 8.0% |

| Specimen Size (Round) | Up to 15 mm diameter |

| Specimen Size (Flat) | Up to 50 mm wide for specimens up to 6.35 mm thick Up to 19 mm wide for specimens 6.35 mm to 12.5 mm thick |

| Catalog Number | CP118413 |

2632 Series

High temperature strain gauge extensometers suitable for use up to 1000°C in a resistance furnace. These extensometers are particularly suited to low cycle fatigue, creep, and stress relaxation testing. The extensometer attaches to a specimen using ceramic wrap-around cord (supplied) or by using a spring type attachment (catalog no. 2632-061). These extensometers are compatible with 3117-150, 3117-152, and 3117-200 furnaces.

| Gauge Length | % Travel (Axial) | Chisel and End Rods | Catalog No. |

| 12.5 mm | +20% / -10% | Quartz | 2632-054 |

| 12.5 mm | +20% / -10% | Alumina | 2632-055 |

| 25 mm | +10% / -5% | Quartz | 2632-056 |

| 25 mm | +10% / -5% | Alumina | 2632-057 |

E-Series

The E-Series high temperature extensometer is a self-supporting, side-entry axial strain gauge designed for use in furnaces with a slot for extensometers or with an induction heating system. The device uses a ceramic fiber cords to attach the extensometer to the specimen.

| Gauge Length | % Travel (Axial) | Catalog No. |

| 25 mm | ± 20% | W-E418-25 |

| 50 mm | ± 20% | W-E418-50 |

非接触式高级视频引伸计

Instron 的高级视频引伸计 AVE2 除了在静态测试中表现出色外,现在还可用于循环试验和高速单调测试测量。这款轻便的非接触式引伸计设计精巧,便于在不同系统间轻松切换,可在实验室内快速移动,为希望在不接触试样的情况下研究材料动态行为的科研人员、工程师和质量专家提供了极大的灵活性。

优化的动态测试能力

采用非接触式动态应变控制和测量技术

探索更多可能

高级的非接触式解决方案

这种非接触式引伸计最大程度地减少了测试环境和操作人员的影响,防止试样过早断裂,从而获得更加一致、准确和可重复的数据。

防衍射气流系统

典型的实验室环境会受到气流变化的影响,从而产生高达几微米的误差。因此,为了最大限度地提高测试精度,AVE2 采用了获得专利的 CDAT 风扇,可在试样和相机之间产生稳定的层流气流,即使在测试过程中空调处于运行状态,也能在自由场空间中产生一致的结果。

交叉偏振照明系统

不同的实验室有不同的光照条件,而且随着时间的推移,同一房间的光照水平也会发生变化,这种差异会导致同一类型的试验结果出现差异。为了确保 AVE2 看到的图像是一致的,Instron 开发了获得专利的交叉极化照明系统,该系统能够在不同实验室光照条件下均实现可重复的试验结果。

全集成的解决方案

该解决方案能够长期稳定地提供所需的测试结果,同时也能适应实验室不断变化的需求。该系统兼容多种环境箱、水浴槽、可选配镜头和附件,且都可通过我司专有测试软件解锁,因此其潜在的测试应用几乎是无限的。

前瞻性动态性能技术

适用于多种循环与单调测试

与夹持式引伸计等传统替代产品相比,AVE2 的灵活性和可用性都得到了提高,除了拉伸和压缩试验外,AVE2 还能便捷测量和控制各种材料和试样几何形状的循环应变。现在,您仅需实验室中的一台设备,就能测量多种规格长度和不同伸长率的试样。

高级的的视频引伸计 AVE2 可与一系列

Instron 动态疲劳试验系统配合使用

ElectroPuls® 全电子

动静态疲劳试验系统

通用型

电液伺服疲劳系统

资讯

工作原理

AutoX750 与 Instron 的 3360、3380、3400、5500、5960、5980 和 6800 系列电子万能材料试验系统以及 LX、DX、HDX 和 KPX 静态液压试验系统集成,并通过 USB 接口由 Bluehill® Universal 测试软件控制。该软件提供易于使用的试验序列和设置,有助于在试验前后自动调整标距、参考臂位置以及臂的打开和关闭。

测量臂采用平衡技术,几乎无重量,因此可消除对被测材料性能的影响。测量臂由电机驱动,每次均可自动定位至正确位置及标距长度。

应用范围

AutoX750 的高精度和长行程使其成为理想的引伸计,可适用于包括金属、塑料和复合材料在内的所有材料

可以测定各种计算结果,包括模量、偏置屈服、断裂塑性伸长率(非比例伸长)以及板材的 r 和 n 值。

对于有特定对中要求的应用,AlignPRO 系统可用于控制加载链的同心度和角度,从而优化对中效果。该系统包括一个安装在载荷传感器与横梁之间的 AlignPRO 工装,用于调整同心度和角度偏差。AlignPRO 软件可监测安装在平面或圆形对中单元上的应变片输出信号。通过这些输出数据计算因角度误差和同心度误差导致的弯曲变形,操作人员可在 AlignPRO 软件中实时监测弯曲变化效果的同时,通过对中装置进行精确调整。

| 规格 | |

| 目录编号 | 说明 |

| 2910-130 | 用于 100 kN(22 kip)电子万能材料试验系统 |

| 2910-132 | 用于 150 和 250 kN(34 和 56 kip)电子万能材料试验系统 |

| 8000-082 | 用于疲劳系统 - 最大载荷范围至 250 kN (56 kip) |

| 8000-084 | 用于疲劳系统 - 最大载荷范围至 500 kN (112 kip) |

| 规格 | |

| 目录编号 | 说明 |

| 8000-171 | 含应变片的对中试样,8 组应变片,直径 8 mm |

| 8000-172 | 含应变片的对中试样,8 组应变片,直径 10 mm |

| 8000-173 | 含应变片的对中试样,8 组应变片,平板 12 mm x 6 mm |

| 8000-174 | 含应变片的对中试样,8 组应变片,平板 15 mm x 2 mm |

配有获得专利的自对中机械同步结构

Instron 液压平推夹具为大载荷测试提供一种创新的解决方案。与传统的夹具设计相比,它具有更卓越的夹持性能、可用性和操作员安全性。该类夹具可在试样上保持恒定的夹持力,该夹持力垂直于测试方向,不会对拉伸载荷产生影响。

Instron 双面平推夹具采用了最新的 DuraSync 技术。与市场上常见的液压或机械齿轮设计相比,这种自对中机械同步结构有诸多改进。

特点

应用范围

| 规格 | ||||||

|---|---|---|---|---|---|---|

| 目录编号 | 力容量 | 平推类型 | 试样尺寸范围 | |||

| 圆棒 | 板材 | 电缆 | ||||

| W-5450 | 250 kN | 双面平推 | 标准 | 3 - 60 毫米 | 0 - 60 毫米 | - |

| W-5400 | 600 kN | 单面平推 | 标准 | 3 - 57 毫米 | 0 - 75 毫米 | - |

| W-5410 | 600 kN | 双面平推 | 标准 | 3 - 60 毫米 | 0 - 100 毫米 | - |

| W-5420 | 600 kN | 双面平推 | 高级 高级型号

高级夹具可用于测试标准板材、圆棒、钢绞线和电缆试样。该型号也可配置用于“过零 ”测试,前提是机架能够承受过零(循环)载荷。 |

3 - 60 毫米 过零试样范围:3 - 60 mm | 0 - 100 毫米 过零试样范围:0 - 75 mm | 4.8 - 25.4 毫米 |

| W-5460 | 1000 kN | 双面平推 | 高级 高级型号

高级夹具可用于测试标准板材、圆棒、钢绞线和电缆试样。该型号也可配置用于“过零 ”测试,前提是机架能够承受过零(循环)载荷。 |

3 - 85 毫米 | 0 - 120 毫米 | 4.8 - 25.4 毫米 |

| W-5430 | 1500 kN | 双面平推 | 高级 高级型号

高级夹具可用于测试标准板材、圆棒、钢绞线和电缆试样。该型号也可配置用于“过零 ”测试,前提是机架能够承受过零(循环)载荷。 |

3 - 85 毫米 过零试样范围:3 - 85 mm | 0 - 120 毫米 过零试样范围:0 - 85 mm | 4.8 - 25.4 毫米 |

| W-5440 | 2000 kN | 双面平推 | 高级 高级型号

高级夹具可用于测试标准板材、圆棒、钢绞线和电缆试样。该型号也可配置用于“过零 ”测试,前提是机架能够承受过零(循环)载荷。 |

3 - 100 毫米 过零试样范围:3 - 85 mm | 0 - 120 毫米 过零试样范围:0 - 85 mm | 4.8 - 25.4 毫米 |

适用于各种材料和试样类型的拉伸试验

手动平推夹具应用广泛,可简单有效地夹持试样。通过双面平推设计,可以调整夹具开口以适应不同的试样厚度,确保试样受力和夹具体在同一轴线上。夹具可以配备各种尺寸的可替换夹面,并可以选择金属光面、橡胶涂层和锯齿等各种表面形式。

2710-100系列| 100 N-10 kN载荷容量

2710-100系列双面平推设计可适用于最大46 mm(1.8 in)厚的试样,对不规则或非对称试样(例如搭接剪切和元件测试)进行补偿。夹具两侧的旋钮上都有滚花,便于手动拧紧,更高载荷的夹具还具有内六角螺钉旋钮,可使用六角扳手或扭矩扳手拧紧试样。夹具上带有刻度,有助于试样居中。

| 载荷容量选项 | 目录编号 |

|---|---|

| 100 N | 2710-111 |

| 500 N | 2710-112 |

| 1 kN | 2710-113 |

| 2 kN | 2710-114 |

| 5 kN | 2710-115 |

| 10 kN | 2710-116 |

高级手动平推夹具

快速更换夹面

快速更换夹面,在不使用工具或销钉的情况下,几秒钟内单手即可更换所有夹面。

简化对中

夹具上带有刻度,便于试样对中。自对中夹面可补偿试样的不规则性。选配的试样对中装置帮助试样对中定位,以提高测试结果的重复性。

通用性

大开口,适用于各种厚度的试样和部件。夹面和夹具体之间的空间较大,便于试样装夹。

夹面类型

供应橡胶涂层、锯齿、金属光面、高摩擦(HFC)、线接触、波纹和V型夹面。

其他型号

中小载荷夹具

适用于多种材料和试样类型的拉伸试验

手动楔形夹具便于试样夹持、对中和定位。夹持样品后,夹持力随着试验载荷的增加而增加。夹具设计为夹具体动,而夹面不动,在试样夹持过程中几乎不会产生预加载,特别适用于测试金属和复合材料等高强度材料,确保试样不打滑。

1 kN - 150 kN 载荷范围

工作原理

这类夹具的楔形作用原理使它们夹紧试样的同时,不会改变夹面相对于试样的垂直位置。这是通过移动夹具主体以闭合夹面的设计实现的。此功能使得可以预先选择特定的点,在该点上以一致的夹面间距夹持试样,并且不会施加可能导致试样屈曲的压缩力。

通过自紧式机构可为难以夹持的材料提供可靠的夹持力。夹面和夹具通过弹簧连接,并通过安装在传动轴上的挡块确保夹面处于固定位置不会在轴向上移动。当夹持试样时,夹具体向上移动的过程中,给夹面一个侧向力,确保夹面水平移动,夹持试样。

夹具采用前部开放式设计,便于更换夹面和夹持试样。由于夹面处于固定位置,在试样破坏时不会产生反冲或松动,如果连接了引伸计,引伸计也将保持在原位。

优势

应用范围

| 适用型号 | ||

|---|---|---|

| 载荷容量 | 最大试样宽度 | 目录编号 |

| 1 kN | 19 mm | 2716-016 |

| 2 kN | 19 mm | 2716-017 |

| 5 kN | 25 mm | 2716-010 |

| 30 kN | 25 mm | 2716-015 |

| 30 kN [高温] | 25 mm | 2736-015 |

| 50 kN | 25 mm | 2716-020 |

| 100 kN | 25 mm | 2716-002 |

| 100 kN | 50 mm | 2716-003 |

| 100 kN [高温] | 25 mm | 2736-004 |

| 100 kN [高温] | 50 mm | 2736-005 |

| 150 kN | 50 mm | 2716-008 |

主要用于薄板、薄膜、柔性塑料、橡胶和弹性体的拉伸试验

自紧式偏心辊拉伸夹具主要用于对弹性体和其他柔性材料进行精密测试,这些材料在受力时横截面积会大幅缩小。该夹具具备卓越的测试精度、可靠的防滑夹持操作,且操作简便快捷。上夹具采用平衡设计,可使试样与载荷传感器对中,从而消除非轴向力。

1 kN - 5 kN 载荷范围

1-kN-Modell | 2713-007

2-kN-Modell | 2713-004

5-kN-Modell | 2713-002

自紧式偏心辊拉伸夹具采用偏心辊夹紧机构。单手快速操作减少了加载试样所需的时间。试样插入极为简便,滚轮支架的弹簧压力提供了正向防滑夹持力。该夹持力足以在施加载荷前固定试样。在试验过程中,辊的后续动作可防止试样在载荷增加时从夹具中滑出。

试样载荷:1 kN 夹具

试样载荷:2 kN 夹具

自紧式偏心辊拉伸夹具

快速插入试样,提高测试效率。

主动的防滑夹持操作,可获取准确的结果。

在施加作用力时,偏心辊的夹持操作会增加夹持力。

专为在 -70° C 至 315° C(-94° F 至 600° F)的温度范围内使用而设计。

小载荷夹具

2620系列引伸计设计用于金属、复合材料、塑料、木材和其他材料总应变高达原始标距的±50%。可浸入各种液体(丙酮、矿物油和硅油、酒精和类似的冷却/加热流体)中,并且可以快速轻松地校准。

| 名称 | 标距 | %行程(轴向) | Cat# |

| 动态引伸计 12.5mm GL ±5mm 行程 | 12,5 ; 25和50mm | ±40, ±20和±10% | 2620-601 |

| 动态引伸计 12.5mm GL ±2.5mm 行程 | 12,5 ; 25和50mm | ±20, ±10和±5% | 2620-602 |

| 动态引伸计 10mm GL ±1mm 行程 | 10, 25和50mm | ±10, ±4和±2% | 2620-603 |

| 动态引伸计 25mm GL +12.5mm -2.5mm 行程 | 25和50 mm | +50 à -10和+25 à -5% | 2620-604 |

2620 系列动态应变片式拉伸计是精确的轻型设备,用于直接测量和闭环控制各种静态和高频循环材料测试应用中的应变。使用 2620 系列动态应变片式拉伸计可进行拉伸、压缩、低和高循环疲劳测试、蠕变和应力松弛以及直线(斜坡)测试,符合各种国家和国际标准。

2620 系列拉伸计设计用于金属、复合材料、塑料、木材和其他材料,其总应变可达原始测量长度的 ±50%。它们可浸入各种液体(丙酮、矿物油和硅油、酒精和类似的冷却/加热液体)中,并可快速、轻松地进行校准。

| 项目名称 | 检具长度 | % 行程(轴向) | 型号 |

| 动态拉伸计 12.5 毫米 GL ±5 毫米行程 | 12.5;25 和 50 毫米 | ±40、±20 和 ±10 | 2620-601 |

| 动态拉伸计 12.5 毫米 GL ±2.5 毫米行程 | 12.5;25 和 50 毫米 | ±20、±10 和 ±5 | 2620-602 |

| 动态拉伸计 10 毫米 GL ±1 毫米行程 | 10、25 和 50 毫米 | ±10、±4 和 ±2 | 2620-603 |

| 动态拉伸计 25mm GL +12.5mm -2.5mm 行程 | 25 和 50 毫米 | +50 à -10 和 +25 à -5 | 2620-604 |

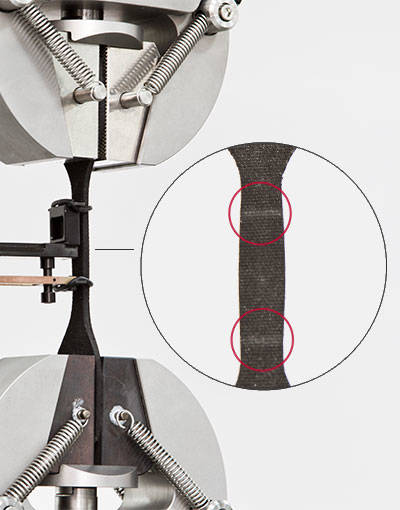

For Testing High Strength Textile Materials

Webbing capstan grips are designed to permit faster, easier testing of seat belts and other high strength belts and tapes. Based on the capstan principle, these grips minimize slippage and jaw breakage effects, and permit the predetermination of specimen length while allowing for quick, convenient loading.

These webbing capstan grips incorporate an ingenious double capstan design which provides fast, easy loading with a gripping action that results in proper breaks in the full gauge length of the specimen. The key to the ease of loading is the use of an inner and outer capstan. The specimen is loaded simply by inserting one end into the groove of the inner capstan and cranking it through 360 degrees. Gripping efficiency is also greatly increased because the surfaces of both capstans are utilized.

| Specifications | |

|---|---|

| Catalog no. | 2715-003 |

| Capacity | 50 kN |

| Standards | ASTM D6775, D3950 |

| Maximum Specimen Width | 50.8 mm |

| Maximum Specimen Thickness | 4.75 mm |

| Temperature Range | -29 °C to 121 °C |

| Upper and Lower Fittings | Type Dm (1.25 in connection with 1/2 in clevis pin). Rigid coupling required. |

| Brochure | Download |

Translation and clamping stages are used to precisely position and align a test specimen below the actuator. These are commonly used for securely positioning microelectronic circuit boards and components within the testing system.

用于测试纤维、绳、纱线和精细编织线

气动绳线夹具为夹持纤维、绳、纱线和细编织线提供了一种便捷的方式,可减少测试时相关材料在钳口处断裂的问题。 一款经过特殊设计的夹头,表面光滑且带有渐变凸轮的曲面轮廓,便于试样装夹,同时可减少试样夹持区域的应力。夹持机器既可以自动启动,也能通过脚踏开关操作。这使得装夹操作无需用手固定夹具,操作人员能用双手轻松装夹试样。气动绳索和纱线夹具可提供可选择的夹持力,以适应不同材料,并且具有出色的随动性能,能够补偿因试样蠕变导致的夹持力衰减。

如果单丝、帘线和纱线的夹持面积相对于强度而言较小,使用常规的夹面通常会导致试样断在夹持处。气动绳索和纱线夹通过摩擦力将夹持力均匀地分布的半绞盘弧面上,从而克服试样提前失效的问题。

此外,施加在试样端部的气动缓冲夹持力可补偿由于试样蠕变引起的夹持力衰减。气动装置激活活动夹块,作用于固定的渐开线夹块上。由此起到绞盘的作用,为试样提供支撑,使试样从自由应力长度逐渐过渡到夹持端,最大程度地减少了试样断在夹面处的可能性。绞盘还装有抛光的导向角,有助于快速加载试样。抛光的表面可防止试样装夹过程中损坏单根纤维。

将试样放置在导向角的顶部,并向下滑动到夹持位置。通过气动脚踏开关可关闭或打开气动夹具,无需双手操作。还可以通过软件或系统默认设置,使用自动气动控制套件解放双手,实现自动和预拉伸测试。

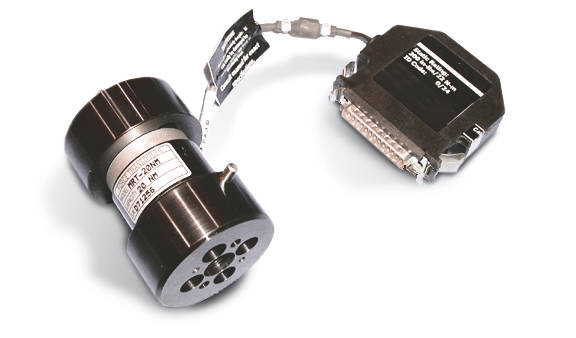

Dynacell 是世界上第一个真正意义上的动态载荷传感器,自设计之初便专为动态载荷测量而打造。Dynacell 在载荷传感器的核心位置 - 轴心安装了加速度计。这一设计消除了因偏心加载而导致加速度读数出现误差的风险。

用于测试部件和结构件

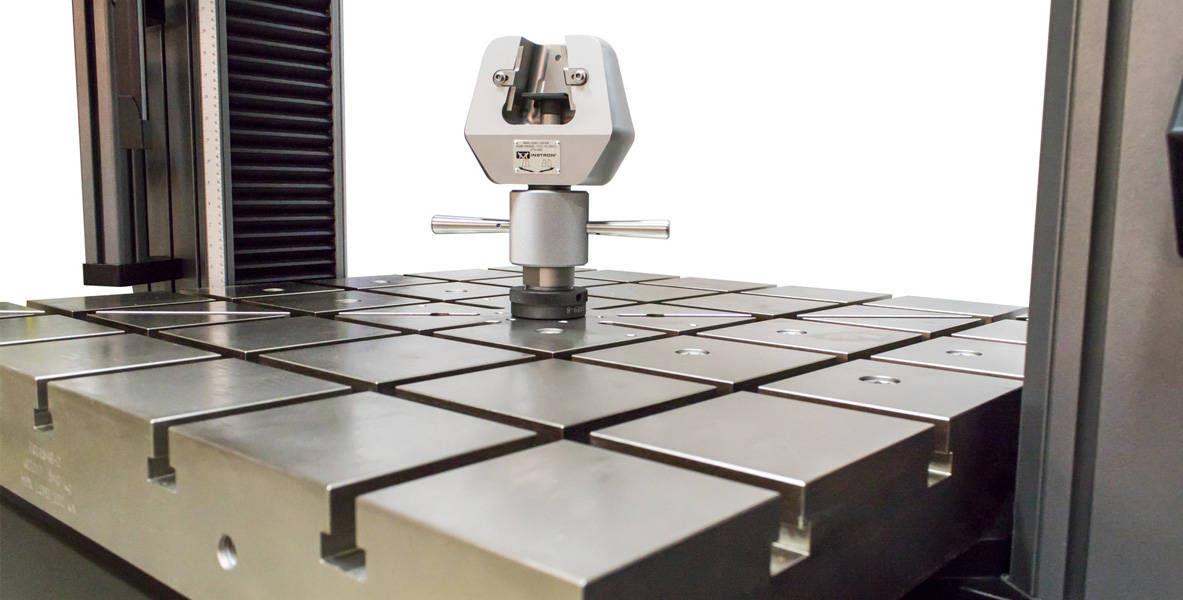

T 型槽平台为电子万能试验机提供了扩展的工作区域,使得用户在进行拉伸、压缩和弯曲测试时,能够更方便地固定部件及结构件。T 型槽平台直接安装在机器底座上,并配备了 T 型槽,该槽可提供样品前后、左右及斜对角线安装方向。然后就可以使用所附的各种夹具将部件和结构件固定在平台的适当位置。借助这种设计,您可以使用标准的 Instron 夹具、测试工装和其他主要配件,无需从机架中移除 T 型槽平台。

T 型槽平台使用户能够使用非标的夹具固定在电子万能试验机上。外购的 T 型槽螺母可先滑入平台的倒 T 型槽。然后可将螺栓、螺柱或螺杆旋拧到螺母中。T 型槽平台可用于固定试样,否则在受力情况下可能会滑出实验区域。

T 型槽平台也可用于将试样放置在同一位置,以实现重复测试和批量测试。可将导轨、滑块或止动器放置在平台上,并用螺栓固定在相应位置,以便在每次测试中精确放置试样。

| 规格 | ||||

|---|---|---|---|---|

| 目录编号 | 最大载荷容量 | 兼容机架 | 宽度 | 深度 |

| CP103964 | 5 kN | 3340、4440、5540、5840、5940、34SC、68SC 单立柱系统 | 200 毫米 | 160 毫米 |

| 2850-206 | 50 kN | 3360 台式试验系统 | 400 毫米 | 500 毫米 |

| 2850-205 | 50 kN | 4460、5560、5860、5960、34TM、68TM 台式试验系统 | 400 毫米 | 500 毫米 |

| 2850-203 | 300 kN | 3382、3384、3385H、34FM-100、34FM-300、4481、4482、4484、4485、5581、5582、5584、5585、5585H、5881、5882、5884、5885、5885H、5982、5984、5985、68FM-100、68FM-300 | 550 毫米 | 500 毫米 |

| 2850-202 | 600 kN | 载荷超过250kN的4400、5500、5800、5900 落地式试验系统 | 640 毫米 | 640 毫米 |

This composite tensile grip guide provides an overview of key specifications for tensile grips that are ideally suited for testing composite materials. For a detailed look at the requirements and important issues related to gripping composite laminate coupons, read our Composites Gripping Guide White Paper.

| Manual Wedge Action Grips | |

| Grip Type | Moving body wedge |

| Static Capacity | 100 kN, 150 kN |

| Operation | Manual |

| Interchangeable | Yes |

| Temperature Range | -70° to 315° C |

| Can You Attach Fixtures Without Removing Grips? Some grips can be outfitted with adaptors to attach other fixtures - offering the flexibility to perform other tests without needing to remove the grips. This is referred to as piggybacking. |

No |

| Nadcap Alignment | No |

| Catalog Numbers | 2716-002, 2716-003, 2716-008, 2736-004, 2736-005 |

| Precision Manual Wedge Grips | |

| Grip Type | Moving body wedge |

| Static Capacity | 100 kN, 250 kN |

| Operation | Manual |

| Interchangeable | Possible (not easy) |

| Temperature Range | -80° to 250° C |

| Can You Attach Fixtures Without Removing Grips?  Some grips can be outfitted with adaptors to attach other fixtures - offering the flexibility to perform other tests without needing to remove the grips. This is referred to as piggybacking. |

Yes |

| Nadcap Alignment | Yes |

| Catalog Numbers | 2716-028, 2716-030 |

| Hydraulic Wedge Action Grips | |

| Grip Type | Moving body wedge |

| Static Capacity | 130 kN, 312 kN, 600 kN |

| Operation | Hydraulic |

| Interchangeable | No |

| Temperature Range | Ambient only |

| Can You Attach Fixtures Without Removing Grips?  Some grips can be outfitted with adaptors to attach other fixtures - offering the flexibility to perform other tests without needing to remove the grips. This is referred to as piggybacking. |

Yes |

| Nadcap Alignment | Yes |

| Catalog Numbers | 2743-401, 2742-501, 2742-601 |

| Extended Hydraulic Wedge Grips | |

| Grip Type | Extended moving body wedge |

| Static Capacity | 130 kN, 312 kN |

| Operation | Hydraulic |

| Interchangeable | No |

| Temperature Range | -70° to 350° C |

| Can You Attach Fixtures Without Removing Grips?  Some grips can be outfitted with adaptors to attach other fixtures - offering the flexibility to perform other tests without needing to remove the grips. This is referred to as piggybacking. |

Yes |

| Nadcap Alignment | Yes |

| Catalog Numbers | CP104947, CP109120 |

Hammer weights and attachment hardware for use with MPX Series frames of equal or greater capacity.

| Description | Catalog No. |

| 300J Hammer Weight | W-3576-A |

| 450J Hammer Weight | W-3576-B |

| 600J Hammer Weight | W-3576-C |

| 750J Hammer Weight | W-3576-D |

Catalog No. W-3577

Kit includes a chain hoist with a capacity of up to 500 kgf (1100 lbf) and a frame mounting bracket to suspend the hoist from an MPX Series pendulum impact machine. This kit is used to easily lift and securely support the hammer weights during weight changes, or the pendulum hammer assembly when replacing the striker, anvils, or other wear components.

Catalog No. W-3598

The Charpy specimen loader device attaches to the MPX frame and uses a manually operated pivoting arm to place individual specimens on the anvil for ambient testing. The arm must be moved away for the door to close and the test to be performed. Kit includes the specimen loader assembly and mounting hardware.

Tongs for handling and centering ambient and low-temperature Charpy and Izod specimens.

| Description | Catalog No. |

| Charpy Tongs | W-3550 |

| Izod Tongs | W-3587-D |

Charpy test kits include a Charpy impact striker, Charpy anvil inserts, and shrouds. These are for use on SI and MPX Series pendulum impact testing systems.

| Description | Catalog No. |

| Charpy Test Kit for ISO 148-2:2009 Includes: Charpy impact striker (2 mm Radius), and Charpy anvil inserts (1 mm radius), and shrouds |

W-3599-A |

| Charpy Test Kit for ASTM E23-12C (also complies with ISO 148-2:2009) Includes Charpy impact striker (8 mm radius), and Charpy anvil inserts (1 mm radius), and shrouds |

W-3599-B |

Catalog No. W-3587-C

Izod test conversion kit includes the components required to convert an MPX and SI Series pendulum impact tester to conduct an Izod test. Included are tongs for specimen handling, a magnetic specimen retrieval device and other necessary tooling. An Izod striker is not included.

Additional or spare Charpy impact strikers can be provided for testing with either a 2 or 8 mm radius.

| Description | Catalog No. |

| Charpy Impact Striker (2 mm radius) for ISO 148-2:2009 | W-3599-C |

| Charpy Impact Striker (8 mm radius) for ASTM E23-12C (also complies with ISO 148-2:2009) | W-3599-D |

Catalog No. W-3587-A

Izod impact striker for machine capacities 240 ft-lbf (325.4 joule) and greater.

Charpy specimen support sets are for use with SI and MPX Series pendulum impact testing systems and are compliant with ASTM E23-12C and ISO 148-1:2009.

| Description | Catalog No. |

| Standard (10 mm x 10 mm) Charpy Specimen Support Set | W-3585 |

| Subsize (7.5 mm x 10 mm Charpy Specimen Support Set (Set of 2) | W-3596 |

| Subsize (5.0 mm x 10 mm Charpy Specimen Support Set (Set of 2) | W-3595 |

| Subsize (2.5 mm x 10 mm Charpy Specimen Support Set | W-3594 |

FTS Charpy Specimen Cooling Bath includes Charpy rack that holds up to 65 specimens and exceeds ASTM E23 / ISO 148 temperature stability requirements.

Note: Performance specifications are based on SP Scientific test data from units using methanol and operating at an ambient room temperature of approximately 22 C (72 F). Higher ambient temperatures and/or different fluids may interfere in the system's ability to achieve its ultimate low temperature.

| Description | Catalog No. |

| 220 V Cooling Bath (50 Hz, 6 AMP) | W-3609-A |

| 120 V Cooling Bath (60 Hz, 12 AMP) | W-3609-B |

Catalog No. W-3558

A centering gauge for positioning Charpy anvil and pendulum.

Catalog No. W-3561

A lateral expansion gauge for impact testing in accordance with ASTM A370.

用于非环境温度下的测试

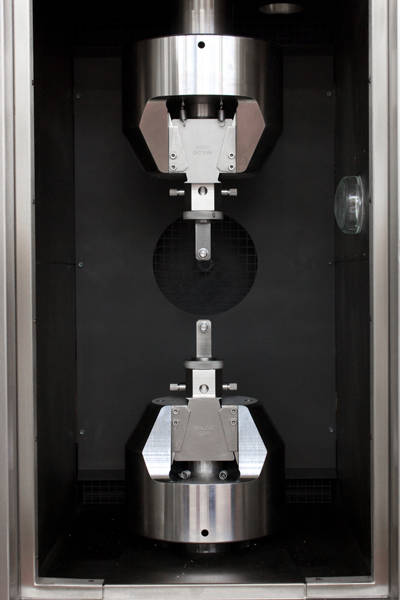

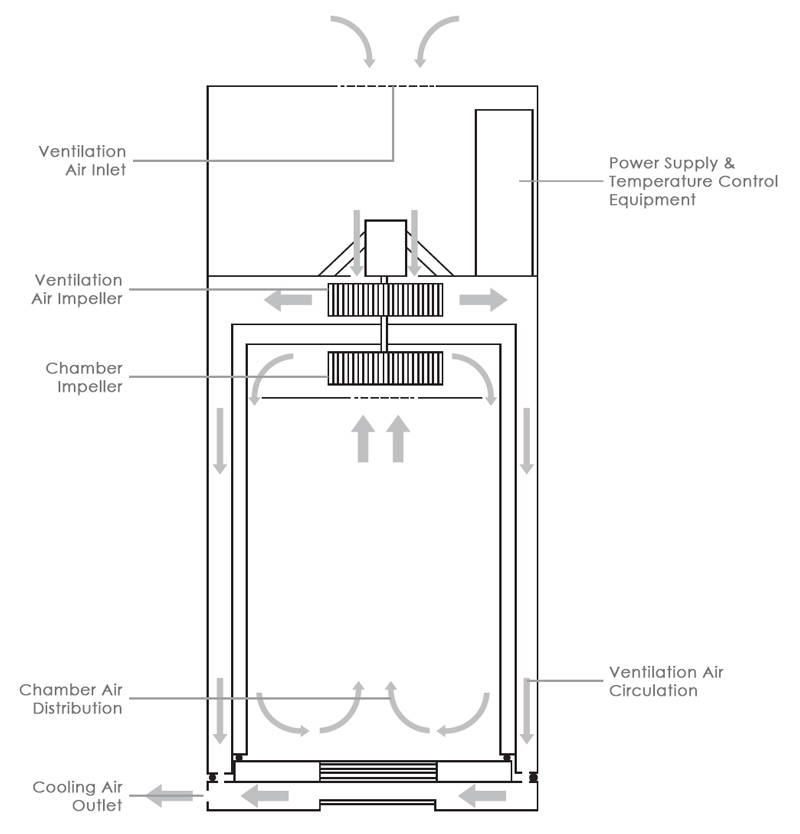

3119-600 系列环境箱兼容静态和动态试验系统,可提供广泛的温度测试能力,用于评估材料再非环境条件下的性能。 环境箱有多种标准尺寸可供选择,可固定在机架上或安装在滚轮支架上。 如果需要,它们也可以通过定制安装件安装到其他品牌的试验系统上。 此外,如果您的应用要求超出我们标准环境箱、夹具和工装的规格,Instron 可以为您定制完整的解决方案,包括加载链组件。

Instron 环境箱采用强制对流原理,热空气或冷空气在试样、夹具和拉杆周围循环,从而提供最佳的加热/冷却速率,减少温度梯度,并实现良好的热稳定性。 常温空气还可以从环境箱的后部进入隔热层和外侧板之间的空间。 这有助于环境箱的外壳保持凉爽。 风扇可选择高/低转速,减少空气流动的影响,让试样得到更精密的测试结果。

空气流经电热元件即可实现加热。 该系列的所有环境箱均标配加热功能。 您也可额外配置冷却阀,通过将低温气体(CO2 或者液氮)吹入环境箱即可实现冷却。 低温气体通常储存在钢瓶(液态 CO2 )或自增压杜瓦瓶(液氮)中。 低温废气通过专用端口排放至环境箱后部,并通过连接到该端口的硅橡胶管将废气排放到实验室外。

打开带有可加热光学玻璃窗的左手式铰链门,即可接触到试样和夹具。 如有需要,内部的灯光可以让您清楚地看到环境箱的内部。 门打开时,环境箱会自动关闭加热、冷却和风扇,从而减少热/冷空气对操作人员的影响。

环境箱中安装的专用 Eurotherm 3208 温度控制器用于选择所需的设定点温度。 温度由环境箱内的 N 型热电偶进行监测和控制。 控制器可以按照规定的加热速率和停留时间(8 段)进行编程,也可以使用兼容的 Instron 软件(通过 USB )与 PC 通信。 它还具有 0-10V 的温度模拟输出,可供图表记录器或其他设备使用。

3119-600 系列环境箱兼容全系列夹具、工装、引伸计和拉杆,可为大量非常温条件下的测试应用提供可靠、持久的性能支持。

| 目录编号 | 温度范围 需要冷却模块才能达到低于环境温度的水平。 | 内部尺寸 深 x 宽 x 高 | 外部尺寸 宽 x 高 |

|---|---|---|---|

| 3119-605 | -100 °C 至 350 °C | 230 x 240 x 485 mm | 350 x 635 mm |

| 3119-606 | -100 °C 至 350 °C | 230 x 240 x 560 mm | 350 x 710 mm |

| 3119-609 | -100 °C 至 350 °C | 230 x 240 x 660 mm | 350 x 810 mm |

| 3119-615 | -100 °C 至 350 °C | 230 x 240 x 860 mm | 350 x 1010 mm |

| 目录编号 | 温度范围 需要冷却模块才能达到低于环境温度的水平。 | 内部尺寸 深 x 宽 x 高 | 外部尺寸 宽 x 高 |

|---|---|---|---|

| 3119-607 | -150 °C 至 350 °C | 400 x 400 x 560 mm | 550 x 710 mm |

| 3119-608 | -150 °C 至 600 °C | 400 x 400 x 560 mm | 550 x 710 mm |

| 3119-610 | -150 °C 至 350 °C | 400 x 400 x 660 mm | 550 x 810 mm |

| 3119-616 | -80 °C 至 350 °C | 400 x 400 x 900 mm | 550 x 1050 mm |

| 3119-617 | -80 °C 至 350 °C | 400 x 400 x 760 mm | 550 x 910 mm |

| 3119-618 | -80 °C 至 350 °C | 400 x 400 x 1000 mm | 550 x 1050 mm |

对于需要超出标准环境箱所能提供的测试应用,我们的工程解决方案团队可根据您的需求为您量身定制专用的环境箱,包括更高或更宽的环境箱、具有更高温度额定值的环境箱以及定制化的加载链组件(如夹具和工装)。

Catalog no. 2715-001

Cord capstan grips are designed to permit faster, easier testing of twisted or braided cords. These grips are designed to permit predetermination of specimen length, and allow quick, convenient loading.

Principle of Operation

Cord capstan grips provide a superior method for clamping twisted or braided cord during testing. Each grip has a round capstan with a right-hand spiral grooved surface that accommodates specimens up to 3.2 mm (0.125 in) in diameter. The capstan is split axially into two halves, one half being stationary and the other movable. The specimen is wound from the outside of the capstan towards the center before being passed through the split halves where it is clamped. The groove completes 2.5 turns around the capstan, which allows two full turns for distributing the specimen load and stress concentration. The grips self tighten as load is applied to the specimen.

Smooth capstan surfaces are available separately.

Application Range

| Specifications | |

|---|---|

| Catalog no. | 2715-001 |

| Force Capacity | 2.5 kN |

| Maximum Specimen Diameter | 3.2 mm |

| Temperature Range | -73 °C to 316 °C |

| View Full Specifications | Download Brochure |

Split insert tensile grips are designed for safe, high-volume production testing of threaded-end, shoulder-end, or button-end machined specimens. Engineered with an operator focus, the split insert style tensile grips are easy to install, offer quick change inserts for standard specimen sizes, and promote efficient static testing of a wide range of metals and alloys. A preferred solution for the testing of high-strength, high-toughness materials that may damage or cause excessive wear to traditional grip arrangements. These grips are designed to comply with ASTM E8, ASTM A370, or ASTM A48, and other international standards, and can be made to custom specifications. A wide range of possible button-end, shank hole, and chamfer / radius dimension options ensures compatibility with a large variety of specimen sizes.

Debris shields, also known as protective shields, provide a protective barrier between the test space and the operator. These may be necessary for materials that exhibit violent failures under test, such as composites, rebar, and cables.

These debris shields feature an anodized extruded aluminum frame and clear Lexan® panels that offer unobstructed views of the text space. A hinged-style access door is available with or without door safety interlocks.

| Compatible Frames | Catalog Number |

| Single Columns | 500 N Systems: 334X, 34SC, 594X, 68SC |

CP127700 |

| Single Columns | 1 - 5 kN Systems | Standard Height: 334X, 34SC, 594X, 68SC |

CP127701 |

| Single Columns | 5 kN Systems| Extra Height: 3345, 34SC-5, 68SC-5 |

CP127702 |

| Table Models | Standard Width: 336X (dual T-slot column cover style only), 34TM, 446X, 556X, 586X, 596X, 68TM |

2910-074 |

| Floor Models: 3382, 3384, 3385H, 34FM, 4481, 4482, 4484, 4485, 5581, 5582, 5584, 5585, 5585H, 5881, 5882, 5884, 5885, 5885H, 5982, 5984, 5985, 5985, 68FM |

2910-062 |

Depending on user-preference and footprint limitations, a sliding debris shield is available for table model universal testing systems. The sheet metal and polycarbonate shield encase the front of the test machine, separating the user from debris and moving parts while also giving excellent visibility. To access the test space, the sliding door is opened to the left and specimens and grips can be loaded through the 845mm tall and 440mm wide port. The debris shield can be equipped with an optional magnetic interlock which prevents tests from being started with the door open and can be configured to prevent all crosshead motion when the door is open.

| Compatible Frames | Catalog Number |

| 68TM, 34TM, 336X, 596X | Standard Height, Standard Width | CP129040 |

| 68TM | Extra Height, Standard Width | CP129044 |

| 34TM, 336X, 596X | Extra Height, Standard Width | CP126003 |

| 336X, 596X | Standard Height, Standard Width | CP126002 |

用于测试成品和部件

部件测试平台是一种钻孔攻丝金属板,可直接安装在单立柱和双立柱试验系统机架的底座上。其表面布满了一系列可用于多种用途的 M6 螺纹孔,可将组件或成品安装到板上进行拉伸、压缩、弯曲、剥离或穿刺试验。您可以借助该测试板偏心安装夹具,便于将定制的工装夹具适配到您的试验系统中。

工作原理

部件或成品可直接使用兼容的 M6 螺纹孔或机械老虎钳固定在部件测试平台上。应选定试样在板上的位置,以便目标区域(即负载处)完全居中。若加载链偏离中心,可能会损坏载荷传感器。

部件测试平台还兼容 Instron 标准底座适配器(O 型和 D 型),可通过平台上的任意 M6 螺纹孔将其安装到测试平台上 - 这便于您将夹具偏心安装,或将定制的工装夹具适配到试验系统上。

应用范围

| 规格 | ||||

|---|---|---|---|---|

| 目录编号 | 适配的试验系统 | 载荷 | 宽度 | 深度 |

| 2910-108 | 单立柱试验系统 68SC |

1 kN | 600 mm | 300 mm |

| 2910-107 | 双立柱试验系统 68TM、34TM、596x、336x、556x、556xA、446x |

2 kN | 300 mm | 300 mm |

| 2910-106 | 单立柱试验系统 334x |

1 kN | 600 mm | 300 mm |

| 2910-105 | 单立柱试验系统 34SC、594x、554x |

1 kN | 600 mm | 300 mm |

| CP129729 | 超宽双立柱试验系统 68TM-30 |

30 kM | 914 mm | 610 mm |

| CP129738 | 双立柱试验系统 68TM、34TM、596x、336x、556x、556xA、446x |

30 kN | 400 mm | 400 mm |

Instron 气动楔形夹具可用于静态或动态材料测试,楔形夹面可灵活互换,无论是平板试样还是圆棒试样,均可适配。

该夹具设计旨在能牢固夹持测试试样,同时不会对试样产生轴向预加载。这是通过采用仅沿水平方向相对于试样移动的夹面得以实现

每个夹具都能独立于另一个夹具工作,外部液压源为夹具的开合供应压力。

当施加夹持压力时,试样与夹面的相对垂直位置保持不变,以避免夹持过程中试样产生负载。

一旦夹面接触到试样后,液压就会在夹面上产生垂直力。由于该设计可自动补偿试样厚度变化,夹具夹持力能保持恒定。

单位

| 产品名称 | 目录 # |

|---|---|

| 2742-103 ±1 kN 气动疲劳夹具 |

2742-103 |

| 2742-205 ±3 kN, ±25 Nm 气动疲劳夹具 |

2742-205 |

| 2742-315 ±10 kN ±100 Nm 气动疲劳夹具 |

2742-315 |

Clevis Grips for Fracture Mechanics

Units

| Item Name | Capacity | Specimen Width | Cat# |

|---|---|---|---|

| Compact Tension Fixtures for 50mm wide Compact Tension Specimens | ±250 dynamic, 500 static kN | 50 mm | 2750-120 |

| High Temperature Clevis Grips | 0.8 @ 1000 deg.C kN | 12.5 mm | 2420C |

| Compact Tension Fixtures for 12.5mm Thick Compact Tension Specimens | ±10 dynamic, 20 static kN | 12.5 mm | 2780-118 |

| Compact Tension Fixtures for 25mm Thick Compact Tension Specimens | ±50 dynamic, 100 static kN | 25 mm | 2780-119 |

| Additional Extension Rod | 2780 120 |

气动楔形夹具的前端开口设计,便于大型试样的轻松装载。该系列可容纳直径最大达 60mm(2.36 in)的圆棒形试样以及厚度最大达 70mm(2.75 in)的平板试样。在安装到 Instron 的落地式试验系统时,这些气动楔形夹具的紧凑型设计可实现试验区域的最大化利用。

这些夹具特别适用于可能存在灰尘和金属碎屑的工业环境,其配备的防尘保护罩可轻松套在夹面外,保护活动表面。可选配的背驮式转接板提供了一种高效方式,无需拆卸大型夹具即可安装次级载荷链,用于小量程试验。

在 2716-110 和 2716-120 型夹具上,用于圆形试样的楔形面在设计上减少了中心区域的面积,这使其在承受高能量断裂时容易受损。而该款夹具采用分体式 V 型夹面设计,能够分散断裂能量,避免夹面受损。对于 W-5180 和 W-5190 型夹具,由于其尺寸显著增大,因此可以采用一体式夹持面设计。

这些夹具通过安装在夹具上的控制旋钮或 Instron 标准气动控制套件进行操作。夹持面由气动控制驱动,通过气动活塞移动,从而省去了昂贵的液压泵及其控制装置。在受力时,楔形作用会提供额外的夹持力,以最大程度减少试样打滑。

2716-110 和 2716-120 型夹具采用独特的托架 / 夹面安装系统,便于快速更换夹面。托架安装在夹具上,通过夹具本体的弹簧固定,并与驱动活塞相抵;夹面则放置在托架上,由几个翼形螺钉固定。夹面托架的润滑通过标准注油嘴进行,无需拆卸夹面或托架即可完成注油。每套夹面可适配多种试样类型,只需更换极少次数的夹面就能满足不同需求,灵活性很强。

W - 5180 和 W - 5190 夹具的夹面安装系统带有嵌入式磁铁和带有圆形定心盘的夹面。这种设计简化了夹面的装载过程,并且在无载荷施加时能使夹面保持在相应位置。

单位

| 测试项目名称 | 载荷 | 上部配件 | 目录编号 |

|---|---|---|---|

| 气动楔形夹具;载荷:100 kN |

100 kN 22,500 lbf |

0.5 in 销钉(Dm 型) |

2716-111 |

| 气动楔形夹具;载荷:200 kN |

200 kN 45,000 lbf |

M48x2mLH(IImLH 型) |

2716-121 |

W-E404 系列横向引伸计专为测量横向位移而设计。该设备可自行固定于试样表面,适用于任意宽度或直径在 0 至 25 mm(1 in)范围内的试样。

W-E404-A/C/E/F 型(引伸计)通常用于测量复合材料等各种异性材料的泊松比和横向应变。它们常与轴向引伸计配合使用。这些装置可轻松夹持在试样上,并通过内置弹簧固定。其圆形接触边缘有助于保持在试样上的位置。

专用的平均值版本 (2640-010) 可用于确定金属板材的 “r” 值(不适用于泊松比)。

试样位移通过一个高精度双挠曲应变片传感器在单点进行测量,该传感器专为提升强度和性能而设计。

用于 “r 值” 测量的专用版本通过两个独立的高精度双挠曲应变片传感器,在两个点对试样位移进行测量。每个传感器的输出会被合并,以生成一个单一的平均输出。

该设计使这些装置具有极高的耐用性,即使在试样发生断裂的情况下,也可保持安装在试样上。

引伸计安装简便,并配备内置弹簧,可将设备固定在试样上。刀口下方可调节的试样接触杆为引伸计主体提供了良好的稳定性。

单位

| 测试项目名称 | 横向行程 | 目录编号# |

|---|---|---|

| 横向平均引伸计 | 2640-010 | |

| 横向引伸计,范围 +/- 2.5 mm | W-E404-F | |

| 横向引伸计,范围 +/- 0.1 in | W-E404-C | |

| 横向引伸计,范围 +/- 0.5 mm | W-E404-E |

这些平均轴向夹式拉伸计可测量试样两侧的轴向应变。可提供单个平均应变输出或两个独立的轴向应变输出。在任何情况下,使用平均轴向应变都可纠正因错位造成的试样弯曲,从而一致地确定模量等材料属性。独立输出版本可同时监测平均轴向应变和弯曲应变。

拉伸计使用应变片进行测量,由高强度铝、钛和不锈钢制成。所有拉伸计都具有简单、单手操作的特点,可确保结果的一致性,并便于在温室内安全使用。拉伸计具有自动电气校准和传感器识别功能,包括唯一的数字序列号。

伸长计标配锥形触点,建议用于大多数复合材料。还有其他触点可供选择:线状触点,建议用于热塑性塑料等软质材料;矢状触点,最适合用于薄截面测试样本。

单位

| 项目名称 | 旅行轴 | 型号 |

|---|---|---|

| 平均拉伸计,25 毫米量规长度,+5 / -2% 应变,单输出 | -2 至 +5 | 2650-560 |

| 平均拉伸计,1 英寸量规长度,+5 / -2% 应变,单输出 | -2 至 +5 | 2650-564 |

Instron 2650 系列双轴引伸计非常适合测试各种材料,包括聚合物基复合材料、金属和塑料,且可在不同温度范围内进行测试。两个传感器分别测量试样两侧的轴向应变,第三个传感器测量横向应变。这些引伸计符合 ASTM E83 类 B1、ISO 9513 类 0.5 以及 ISO 527 的校准要求。

这些双轴夹持式引伸计使用应变片进行测量,并由高强度铝、钛和不锈钢制成。所有引伸计均具有简单的单手操作功能,这不仅能确保测试结果的一致性,还有助于在环境箱内安全使用。此外,该引伸计集成了自动电气校准和传感器识别功能,包括一个独特的数字序列号。

所有引伸计均可测量试样两侧的轴向应变,部分版本可提供单一平均轴向应变输出或两个独立的轴向应变输出。在所有情况下,采用平均轴向应变都能校正因对准偏差导致的试样弯曲,从而保证弹性模量测定结果的一致性与准确性。独立输出版本能够同时监测平均轴向应变和弯曲应变。此外,该引伸计还配有测量横向应变的传感器,可用于测定泊松比、面内剪切模量等材料性能参数。

锥形接触点作为标准配置随引伸计提供,并推荐用于大多数复合材料。还提供其他接触选项:线接触点,推荐用于热塑性塑料等软材料;以及 V 型接触点,最适合用于薄壁试样。

单位

气动式和制动式拉伸夹具用于测试绳索、轮胎帘线、钢丝、电缆、纱线和纤维束试样。

Instron® Crack Opening Displacement transducers are designed

specifically to perform standard ASTM and ISO fracture mechanics

tests (both cyclic and static), covering all common specimen

geometries (CT, SEB, Centre Crack, Arc Shaped).

Each model offers class leading linearity, whilst being rugged

enough to withstand the high energy release common in many

of these applications and can be used at both elevated and sub

ambient temperatures.

These gauges comply with requirements laid down in ASTM E399-09.

These machines are developed to obtain specimens by punching, using hollow dies of different sizes and contours. Several hundreds of dies can be created by interchangeable socket punches with different profiles and size according to the standards and to the customer needs. Dies are made of steel with hand finished cutting edges and can be provided with ejector for easy removal of the specimen after punching.

Compact design of instrument for an easy and fast preparation

Manual and automatic models obtain specimens of different size and geometries for a wide range of plastics testing applications

High level of results repeatability and time saving test procedures

The Custom Solutions group at Instron has been developing unique grips and platens to meet our customers’ unique needs for decades. Customized cord and yarn grips or custom webbing grips of various sizes are just a small example of things that we can do. Whether your grip or platen is being purchased with a new frame or being used with your current set-up, we will work diligently to understand your goals and ensure they are met or exceeded. Please browse the gallery above to see some of our recent projects.

We also make specialized jaw faces!

Click here to see our existing customized grips or platens for specific applications.

Requires: grip faces and fatigue rated adapters

Quantity: 2 grips

| Notes | For holding PCBs and assemblies |

| Accessory Height | 101 mm (4 in) |

| Accessory Width | 84 mm (3.3125 in) |

| Capacity | 2.22 kN (500 lbf) |

| Effective Length | 139 mm (5.472 in) |

| Lower Fitting | 6 mm clevis pin (Type Om) |

| Specimen Diameter | 0.125 - 1.5 mm (0.005 - 0.06 in) |

| Temperature Rating | +10 to +40 °C (+50 to +150 °F) |

| Upper Fitting | 6 mm clevis pin (Type Om) |

The Custom Solutions group at Instron has been developing unique fixtures to meet our customers’ unique needs for decades. If you need to push or pull against something unique or novel, like yak hair or pizza dough, we are interested in learning more about it. Whether your fixture is being purchased with a new frame or being used with your current set-up, we will work diligently to understand your goals and ensure they are met or exceeded. Please browse the gallery above to see some of our recent projects.

Click here to see our existing customized fixtures for specific applications.

Transverse Averaging Extensometer with single channel output for attachment to thin rigid specimens, 0.3 mm to 4 mm thick.

Accepts specimens from 10 mm to 20 mm wide and from 15 mm to 25 mm wide. Suitable for ´r´ and ´n´ testing on sheet metals.

Requires suitable axial extensometer of 50 mm gauge length minimum for ´r´ value determination. Requires single strain conditioner.

Temperature Range: -80 °C to +100 °C

The 2640 series averaging transverse extensometer is designed to measure average transverse gauge length and strain with a single output channel.

| Accessory Weight | 0.65 kg (1.4 lb) |

| Specimen Zone | 200 mm (8 in) |

| Specimen Thickness | 50 mm (2 in) |

| Specimen Width | 50 mm (2 in) |

| Testing Standards | BS 373, ASTM D 143 |

| Upper Effective Length | 150 mm (6 in) |

Digital caliper with carbide standard jaws. Resolution of 0.0005" (0.01mm). Accuracy of ±0.001" (±0.02mm). Repeatability of 0.0005" (0.01mm).

Designed to be used in conjunction with Automatic Data Entry Interface listed separately. Qualifies as one (1) device. Includes case.

Note: This measuring device requires an Automatic Data Entry Interface listed separately for direct entry of measurements into software.

Biaxial Extensometer 2 inch Gauge Length providing one averaged axial and one transverse strain measurement.

Features:

Transverse Travel +/- 0.02 in (Strain range depends on specimen width)

The extensometer provides a single averaged axial output along with a single transverse output and requires 2 Sensor channels. It has electrical calibration and is self-identifying with 3300, 3400, 4200, 4300, 4400, 4500, 5500, 5800, 5900, 6800, 8500, 8800 Tower, and 8800MT Series Systems.

The extensometer is supplied with a single set of conical point specimen contacts.

These bi-axial and averaging axial clip-on extensometers use strain gauges for measurement and are constructed from high-strength aluminum, titanium, and stainless steel. All of the extensometers feature simple, single-handed operation. The extensometer incorporates automatic electrical calibration and transducer recognition including a unique digital serial number.

Instead of working with a pallet mounted onto the crash sled, the patented Instron two piece sled integrates the pallet system into the sled design. This allows for much faster set up times using multiple pallets whilst significantly reducing the overall mass of the sled to provide a higher dynamic performance.

The pallets can be tailored to meet the specific needs of the test laboratory.

Back to CSA.

| Gauge Length | 0.50 in |

Capacity 300 kN (67,500 lbf, 30,000 kgf)

Specimen Range:

Minimum Specimen Length without the use of an extensometer is 270 mm (10.63 in)

Ambient temperature use only.

Upper and Lower Fittings: Type IIfRH (M48 x 2)

Weight Per Grip Body 123 kg (270 lb)

Grip Body Dimensions W x L x D: 445 x 302 x 127 mm (17.5 x 11.875 x 5 in)

Effective Length using standard threaded mounting:

Grip faces sold separately use: W-5246 & W-5247 series grip faces

Configuration Notes:

| Accessory Weight | 123 kg (270 lb) |

| Accessory Width | 445 mm (17.5 in) |

| Capacity | 300 kN (67,500 lbf) |

| Lower Fitting | Type IIfRH (M48x2) |

| Temperature Rating | 10-38 °C (50-100 °F) |

| Upper Effective Length | 329 mm (13.0 in) |

| Upper Fitting | Type IIfRH (M48x2) |

Biaxial Extensometer 1 inch Gauge Length providing one averaged axial and one transverse strain measurement.

Features:

Transverse Travel +/- 0.02 in (Strain range depends on specimen width)

The extensometer provides a single averaged axial output along with a single transverse output and requires 2 Sensor channels. It has electrical calibration and is self-identifying with 3300, 3400, 4200, 4300, 4400, 4500, 5500, 5800, 5900, 6800, 8500, 8800 Tower, and 8800MT Series Systems.

The extensometer is supplied with a single set of conical point specimen contacts.

These bi-axial and averaging axial clip-on extensometers use strain gauges for measurement and are constructed from high-strength aluminum, titanium, and stainless steel. All of the extensometers feature simple, single-handed operation. The extensometer incorporates automatic electrical calibration and transducer recognition including a unique digital serial number.

Flat-end puncture probes produce a shear stress in the specimen. The force required to cause shearing as the probe penetrates the specimen relates to texture properties such as firmness and hardness.

500 kN (110 kip) Dynamic Capacity, With 100mm (3.94 in) Diameter Upper Roller and 50mm (1.97 in) Diameter Lower Rollers

Requires: fatigue rated adapters

Catalog number 2810-250

Rated capacity 500 kN (50000 kgf, 112500 lbf)

3-point flexure fixture with an optional conversion kit for 4-point loading

| Compatible Frame Models | Air Cushion Isolators (for frames 3 & 4). Not suitable for 8801 or 8516 Suitable for testing frequ |

For mounting ElectroPuls table-top systems when used for low to medium acceleration dynamic tests (accelerations below 6g)

Robust design with high stiffness grey frame and light-grey scratch-resistant table-top

Pre-drilled with mounting holes to suit E1000 or E3000 systems

| Model | Height | Width | Depth | Weight | ||||

|---|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | kg | lb | |

| 1300-311 | 785 | 31 | 1000 | 39 | 750 | 30 | 56 | 123 |

| 1300-315 | 800 | 32 | 1000 | 39 | 750 | 30 | 65 | 143 |

High-Stiffness Support Table for ElectroPuls E1000 and E3000 tabletop test instruments.

| Gauge Length | 25/50 mm |

Dynamic Extensometer for direct strain measurement and closed loop strain control. Suitable for tensile, compressive & fatigue testing, the extensometer has a 12.5mm gauge length with a travel of ±5mm giving ±40% strain.

It includes a 12.5mm extender to give a gauge length of 25mm and ±20% strain and a 37.5mm extender to give a gauge length of 50mm and strain of ±10%.

Temperature range: -80C to +200C. Compatible with 8800 and 8500Plus controllers. May be immersed in acetone, silicone or alcohol.

Wide operating temperature range, from -80 °C to 200 °C (-112 °F to 392 °F)

Designed to meet the requirements of ISO 9513, BS 3846 and ASTM E 83

This guide provides instructions on how to use your system components and controls, procedures for setting limits, calibration and other frequently performed operating tasks.

Fracture Mechanics Fixtures for 50 mm wide compact tension specimen.

Rated capacity: ±250kN Dynamic, 500 kN Static

Requires: fatigue rated adapters. Mechanical interface M48 x 2 right hand female thread.

(1 Pair)

Supports closed-loop control and data acquisition for only one transducer (strain gage bridge, LVDT, or +/-10V BNC input).

Includes:

Note: Not recommended for customer installation to an existing tower. Always include service time when quoting as an accessory

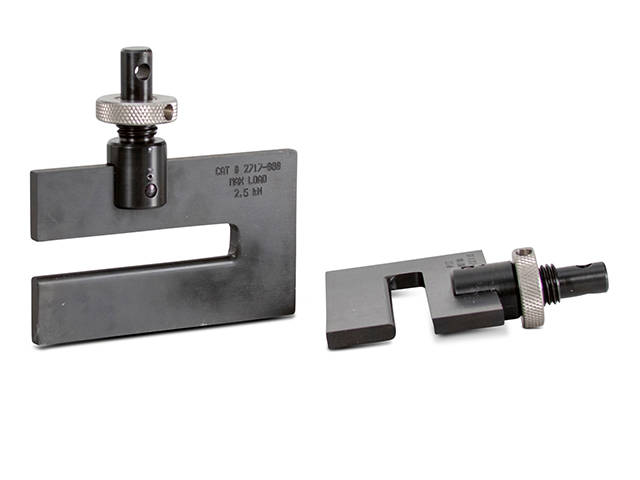

| 附件身高 | 356 mm (14 in) |

| Accessory Width | 125 mm (5 in) |

| 容量 | 2.5 kN (500 lbf) |

| Lower Fitting | 1/2 inch Clevis Pin (Type Dm) |

| Temperature Rating | +10 to +40 °C (+50 to +100 °F) |

| Testing Standards | MIL-STD-3010 |

| Upper Fitting | 6 mm Clevis Pin (Type Om) |

Digital micrometer with flat anvils for measuring outside diameter and thickness. Resolution of 0.00005" (0.001mm). Accuracy of ±0.0001" (±0.002mm).

Designed to be used in conjunction with Automatic Data Entry Interface listed separately. Qualifies as one (1) device. Includes case.

Note: This measuring device requires an Automatic Data Entry Interface listed separately for direct entry of measurements into software.

Partner Interface that translates and routes data from a device with an RS-232 output into the Partner software (i.e. micrometer, caliper, barcode reader, etc).

Allows the use of up to two (2) such devices. Requires one (1) PC serial port.

Includes all necessary hardware and software.

Notes:

Capacity: 5.0 kN (1,000 lb, 500 kg).

Incorporates a surfalloy coated clamping surface.

Temperature range: -10 °C to 80 °C (14 °F to 176 °F).

Maximum specimen diameter: 2 mm (0.08 in).

Upper and lower fittings: Type Dm (1.25 in connection with ½ in clevis pin).

Requires a rigid coupling and an Automatic Air Control Kit or Pneumatic Foot Switch

The Instron® pneumatic tire cord grips provide a convenient method for clamping tire cord and braided wire during testing. A guide pin allows for easy loading onto a graduated radius cam, which provides a stress-reduced clamping area on the specimen. The clamping mechanism can be activated either automatically or through a footswitch, which allows for hands-free grip operation enabling the specimen to be held with both hands for easy loading. Pneumatic cord and yarn grips provide selectable clamping force to accommodate different materials and excellent follow-up action that compensates for decay of the holding force due to specimen creep.

Notching machines are designed to notch specimens for impact resilience according to Izod, Charpy and Tensile impact methods. These instruments use a linear knife cutting technique to avoid overheating and consequent stresses during the specimen's notching operations. Therefore, an accurate notch preparation is guaranteed. Manual, motorized and fully-automatic models are available to cover the different testing needs.

Rated Capacity: ±50kN Dynamic, 100kN Static

Temperature Range: -50 to 315°C

Overall accessory length 400mm

Includes:

Capacity 2000kN

(450,000 lbf, 200,000 kgf)

Specimen ranges:

Grips are supplied with:

Grips interfaced to the machine’s hydraulic power supply when ordered with a new hydraulic UTM. (Consult factory for interfacing of grips to an existing machine or for systems where an independent hydraulic power supply is required)

Efective grip heights:

Upper grip: 715 mm (28.125 in.)

Lower Grip: 770 mm (30.3125 in.)

Flat-end puncture probes produce a shear stress in the specimen. The force required to cause shearing as the probe penetrates the specimen relates to texture properties such as firmness and hardness.

Averaging Extensometer 25 mm Axial Gauge Length providing a single averaged axial output.

Features:

The extensometer provides a single averaged axial output. It has electrical calibration and is self-identifying with 3300, 3400, 4200, 4300, 4400, 4500, 5500, 5800, 5900, 6800, 8500, 8800 Tower, and 8800MT Series Systems.

These bi-axial and averaging axial clip-on extensometers use strain gauges for measurement and are constructed from high-strength aluminum, titanium, and stainless steel. All of the extensometers feature simple, single-handed operation. The extensometer incorporates automatic electrical calibration and transducer recognition including a unique digital serial number.

| Gauge Length | 8.00 in |

Capacity: 10 kN (2,000 lb, 1,000 kg).

Maximum specimen diameter: 5 mm (0.2 in).

Upper and lower fittings: Type Dm (1.25 in connection with ½ in clevis pin).

Requires a rigid coupling and an Automatic Air Control Kit or Pneumatic Foot Switch

(ref. 2714-107)

| Accessory Weight | 10 kg (22 lb) |

| Accessory Width | 245 mm (9.6 in) |

| Capacity | 10 kN (2250 lbf) |

| Effective Length | 230 mm (9.1 in) |

| Lower Fitting | 1/2 in clevis pin (Type Dm) |

| Specimen Diameter | 5 mm (.2 in) |

| Temperature Rating | -10 to + 80 °C (+14 to +176 °F) |

| Upper Fitting | 1/2 in clevis pin (Type Dm) |

+/- 0.5 mm travel

For general purpose transverse or diametral strain measurement

on axially loaded specimens. Used for measurement of Poisson's ratio,

on anisotropic materials like many composites and similar applications.

Specifications:

W-E404 Series Transverse Extensometers are designed for measuring transverse displacements. They are self-supporting on the test specimen and will work on any width or diameter specimen from 0 to 25 mm(1 in).

Digital caliper with carbide pointed jaws for measuring small holes, grooves, and outer diameters encountered in precision work. Resolution of 0.0005" (0.01mm). Accuracy of ±0.001" (±0.02mm). Repeatability of 0.0005" (0.01mm).

Designed to be used in conjunction with Automatic Data Entry Interface listed separately. Qualifies as one (1) device. Includes case.

Note: This measuring device requires an Automatic Data Entry Interface listed separately for direct entry of measurements into software.

双轴引伸计,50 mm 轴向标距,提供一个平均轴向应变和一个横向应变输出。

特点:

横向行程 +/-0.5(应变范围取决于试样宽度)

该引伸计提供单一的平均轴向输出和单一的横向输出,需占用 2 个传感器通道。它具备电子标定功能,并自识别 3300、3400、4200、4300、4400、4500、5500、5800、5900、6800、8500、8800 Tower 及 8800MT 系列试验系统。

Capacity: 200 kN (40,000 lb, 20,000 kg)

Upper and lower fittings: Type llm (M48 X 2 LH)

Maximum specimen thickness: 40 mm (flat)

Maximum specimen width: 75 mm (flat)

Maximum specimen diameter: 50 mm (round)

Clamping length: 70 mm.

Temperature range: ambient only

Requires faces

Includes an air distribution kit with both, 1/4 NPTM (7/16-20), and 1/4 inch hose barb end connections

An Automatic Air Control Kit or Footswitch is recommended

The Pneumatic Wedge Action Grips, available in 100 or 200 kN, provide a convenient method of clamping both large round and flat specimen shapes, up to a 50 mm (2 in) diameter, or flat specimens up to 40 mm (1.57 in) thick respectively. V-face grips are used for round specimens by design and have a reduced area at the center that compromises their ability to absorb high-energy breaks without fracture. This grip uses a split V-face configuration that allows the break energy to be dissipated without damaging the faces.

The Instron 2718-550 hydraulic grip pump is designed for continuous 24/7 operation in manual and automated testing systems in industrial environments.

It can be configured to provide a maximum pressure of 207 bar (3000 PSI for use with wedge grips), or alternatively 138 bar (1900 PSI) for use with side acting grips. The unit incorporates two analogue pressure gauges, that are easily visible to the operator from the front of the pump.

The 2718-550 pump is configured to operate with a two stage flow speed, with a higher flow rate up to 69bar (1000psi) to increase productivity. Once clamping the specimen the pressure will then increase to the full pressure at the slower flow rate.

The 2718-550 hydraulic grip pump is activated by a footswitch, while a handset provides close/open functionality of each grip independently. The gripping pressure is easily configured by an electrical adjustment knob located on the front of the pump.

| Grip Type | Static Load Capacity | Catalog No. |

| Advanced Hydraulic Wedge Action Grips | ±130 kN | 2743-401 |

| Advanced Hydraulic Wedge Action Grips | ±312 kN | 2742-501 |

| Advanced Hydraulic Wedge Action Grips | ±600 kN | 2742-601 |

| Hydraulic Dual Side Action Grips | 250 kN | W-5450 |

| Hydraulic Dual Side Action Grips | 600 kN | W-5420 |

The Instron® 2718-550 hydraulic grip pump is designed for continuous 24/7 operation for both manual and automated testing systems in industrial environments

| Accessory Length | 60.3 mm (2.375 in) |

| Lower Fitting | M12x1.75mRH |

| Specimen Diameter | mm (0.375 - 1.000 in) |

| Torque Capacity | 57 Nm (500 in-lb) |

| Upper Effective Length | 47.6 mm (1.875 in) |

| Upper Fitting | M12x1.75mRH |

The active controlled pitch simulation load unit offers a significant advantage through more realistic crash simulations and better reproduction of the dummy injury criteria. In a frontal impact, the deceleration and deformation of the vehicle body is almost always accompanied by a movement in the vertical plane. In most cases, this movement is a combination of a rotation around a point in the space in front of the vehicle with an additional vertical movement.

Pitching in crash events directly influences the acceleration and the movement path of the occupant during an impact. These movements together with the strong frontal deceleration during the impact determine the severity of the injury in interaction with the seatbelt and airbag. One focus of security system development is the management of the Head Injury Criteria (HIC) value. Earlier analyzes have shown up to 40% difference between the HIC values of sled tests with and without the possibility of pitch motion simulation. Further influences are found for neck accelerations and belt forces.

The Instron CSA systems with active pitch simulation are currently successfully used by 14 customers.

Back to CSA

| Compatible Frame Models | Isolation mounts for 8801 or 8516 (1 set). For testing frequencies above 15Hz. |

Instron® testing systems provide an accurate measurement of force during a test, but in order to produce accurate stress results, you must measure the specimen and get the dimensional data into Bluehill® Universal Software. While digital instruments, such as micrometers, can provide accurate measurements, using them properly takes time and requires the operator to manually enter the dimensional data into the software.

| Description | Air Compressor, portable. Line Voltage: 240 VAC. |

Biaxial Extensometer 50 mm Axial Gauge Length providing 2 independent axial and one transverse strain measurement.

Features:

Transverse travel +/- 0.5 mm (Strain range depends on specimen width)

The extensometer provides 2 independent axial outputs along with a single transverse output and requires 3 sensor channels. It has electrical calibration and is self-identifying with 3300, 3400, 4200, 4300, 4400, 4500, 5500, 5800, 5900, 6800, 8500, 8800 Tower, and 8800MT Series Systems. The extensometer is supplied with a single set of conical point specimen contacts.

These bi-axial and averaging axial clip-on extensometers use strain gauges for measurement and are constructed from high-strength aluminum, titanium, and stainless steel. All of the extensometers feature simple, single-handed operation. The extensometer incorporates automatic electrical calibration and transducer recognition including a unique digital serial number.

Capacity: 500 N (100 lb, 50 kgf)

Includes a single grip with lead pull jaw faces.

Temperature range: 0°C to 60°C (32°F to 140°F).

Fitting: Type Om (12 mm connection with 6 mm clevis pin). The pneumatic lead pull grip is a parallel action pneumatically operated vice action grip fitted with needle nose jaw faces for lead pull testing.

Requires an automatic air kit.

1 Grip Only.

| Accessory Height |

152 mm (6 in) |

|---|---|

| Accessory Width |

139 mm (5.5 in) |

| Capacity |

36 kN (8000 lbf) |

| Effective Length |

213 mm (8.375 in) |

| Lower Fitting |

1/2 in clevis pin (Type Dm) |

| Specimen Diameter |

0.8 - 6.5 mm (0.0312 - 0.25 in) |

| Temperature Rating |

+10 to +40°C (+50 to +150°F) |

| Upper Fitting |

1/2 in clevis pin (Type Dm) |

Features:

Includes side port insulation plug for blanking extensometer slot.

Requires temperature controller with thermocouples, support brackets, and top/bottom insulating port plugs (not included)

Z-Direction Tensile.

Fixture includes two test blocks and tabs.

Requires a set of grips, not included.

| Description |

TAPPI T541 Internal Bond Strength of Paperboard. Z-Direction Tensile. |

|---|---|

| Lower Fitting |

Requires upper and lower grip |

| Testing Standards |

TAPPI T541 |

| Upper Fitting |

Requires upper and lower grip |

Fatigue Rated 3 Point Bend Fixture, 100 kN (22 kip) Dynamic Capacity, With 25mm (1.0 in) Diameter Rollers

Includes: One upper roller, 25 mm (0.97 in) Diameter

Requires: fatigue rated adapters

Side crashes are the second most common type of accident. They cause the highest number of critical injuries relative to the accident rate. One reason for this is the spatial proximity of the occupant to the deformation zone. There are different test standards for the side impact. These are the side crash according to ECE-R95 (European standard) and FMVSS-214 (US standard) as well as the tests given in the consumer protection programs. In addition to the actual side impact test, there is also a Pole Side Impact test according to Euro NCAP.