Composite Test Fixtures

Characterization of composite materials requires a range of tests under different loading conditions, such as tension, compression, shear, flexure, and peel. Instron provides a range of high-performance composites testing fixtures that conform to the requirements of the appropriate ASTM, ISO, EN, and other testing standards.

Both manual and hydraulic grip types capable of operating over a wide range of temperatures are available. Moving body manual and hydraulic wedge grips are recommended for testing composite materials as they provide reliable gripping of test specimens whilst maintaining accurate and repeatable alignment meeting Nadcap requirements for aerospace testing. Adapters are available to allow a range of composites test fixtures to be attached to these grips meaning that the grips do not have to be removed when changing test set ups, minimizing disruption and enhancing productivity.

Supported Gauge Section

| Overview | |

| Common Standards | ASTM D695, ASTM D3846, Boeing BSS 7260, SACMA SRM-1, prEN 2850, ISO 14126 |

| Catalog Numbers | S4931A, CP108932, CP114221, CP114215, CP115010, CP115011, CP114249 |

Unsupported Gauge Section

Boeing Open Hole Compression Fixture

| Overview | |

| Common Standards | ASTM D6484, ASTM D6484M, Boeing BSS 7260 |

| Catalog Numbers | CP113777, CP113778, CP113779, CP113780 |

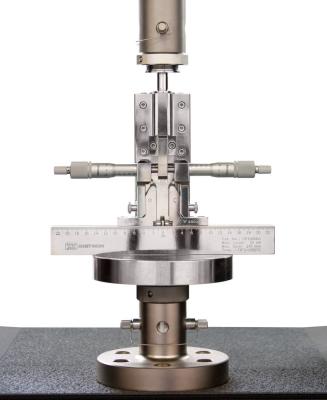

Composites V-Notch Shear Test Fixtures

Instron Shear Test Fixtures are designed for in-plane or interlaminar shear testing of composite materials. The V-Notched Beam Method, or more commonly known as the Iosipescu Shear Method, was standardized into ASTM D5379 in 1993, while the V-Notched Rail Shear Method was more recently introduced in 2005 under ASTM D7078. Both test methods share many common characteristics and have the distinctive V-notches in the specimen design, which serve to create a localized and approximate uniform shear stress zone between the notches. It’s important to note that the two fixtures in ASTM D7078 and D5379 are quite different in their specimen design, the way in which load is applied to the specimen and consequently, the type of results obtained.

| Overview | |

| Common Standards | ASTM D5379, ASTM D7078 |

| Catalog Numbers | S4685A, CP105207 |

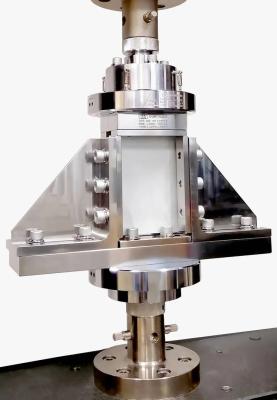

Composites Rail Shear to ASTM D4255

ASTM D4255 describes both 2 Rail and 3 rail methods of determining the in-plane shear strength of a composite laminate panel. In the 2 Rail test (Method A) a laminate panel specimen is clamped between loading plates and yokes and then subject to shear loading. Measurement of shear strain requires the use of strain gauges on the specimen. Two types of fixture are available: one working in a compression mode and one working in a tension mode. A specimen template is included to ensure the accurate location of the holes in the specimen.

| Overview | |

| Common Standard | ASTM D4255 |

| Catalog Numbers | S4695A, S4695B |

Flexural and Interlaminar Shear Bend Fixture

A modular fixture for flexural and Interlaminar Shear Strength (ILSS) testing to a wide range of standards. Capable of operation from -70 to +250 deg C (-94 to +482 deg F).

"Boeing CAI" Fixture

| Overview | |

| Common Standards | ASTM D7137 / 7137M, Boeing BSS 7260 |

| Catalog Numbers | S5385A, CP103712 |

Airbus AITM 1-0010

| Overview | |

| Common Standard | AITM 1-0010 |

| Catalog Number | CP105079 |

Sandwich Constructions Flatwise Tension Test Fixtures

ASTM C297 describes a method of determining the bond strength between the facing and core of a sandwich core panel or the strength of the core itself, if the bond strength between the facing and the core is sufficiently strong. The specimen is bonded to thick loading blocks and then subject to tensile loading applied via the blocks. Each half of the test fixture incorporates a dual flexible yoke to ensure that pure axial load is applied to the specimen. The fixture can be used to test a variety of different sandwich core materials including honeycomb core structures and continuous core structures, such as foam or balsa wood.

Flatwise Shear to ASTM C273

| Overview | |

| Common Standard | ASTM C273 |

| Catalog Numbers | S4681A, S4682A |

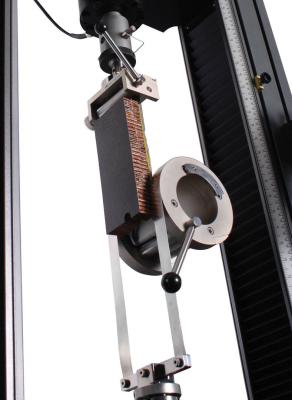

Climbing Drum Peel Fixture

The Climbing Drum peel test for adhesives measures the strength of the adhesive bond between the core and the facing of a honeycomb panel.

| Overview | |

| Common Standards | ASTM D1781, EN 2243-3 |

| Catalog Numbers | S4680A, S4680C, CP108963 |

Strain Gauge Adapters for 120 and 350 ohm Gauges

From aerospace to construction, strain gauges are used in a variety of industries to measure strain in both materials and structural testing. These strain gauge adapters allow a single strain gauge to be used with any standard Instron strain channel. The strain gauge adapter contains bridge completion resistors and electrical calibration circuitry. The strain gauge leads are connected to the adapter via a spring-loaded terminal. Both 2 and 3 wire strain gauge connections are supported. The adapter is compatible with strain gauges that have gauge factors between 1.5 - 2.5. Multiple strain gauges require multiple adapters, which can be used up to the maximum number of strain channels fitted to the testing machine.

| Overview | |

| Catalog Numbers | 2210-891, 2210-892 |

Biaxial Extensometer

A range of Bi-axial and Averaging Axial extensometers are optimized for measuring strain when testing composites. These extensometers feature simple, single- handed operation and incorporate automatic electrical calibration and transducer recognition including a unique digital serial number. All of the extensometers measure the axial strain on both sides of the specimen. The use of average axial strain corrects for any specimen bending due to mis-alignment for the consistent and accurate determination of modulus. Biaxial versions measure transverse strain allowing for the determination of Poisson’s Ratio and In-Plane Shear strain.

| Overview | |

| Standards | Meets ASTM E82 B-1, ISO 9513 grade 0.5 and ISO 527 (annex C) |

| Catalog Number | 2650-561 |