Controller Labtronic® 8800ml

Challenge

In your highly efficient laboratory, you are faced with the challenges of material and structural durability testing every day. You want to use your testing technology efficiently and flexibly while minimizing set-up times? Your customers demand a high degree of flexibility including the ability to integrate external data sources and vehicle control systems? Your operators need the possibility to work in a quiet and safe environment? All of this whilst minimizing the running costs and protecting your capital investments over the long term?

Solution

Together with recognized experts from the automotive industry, we have developed the Labtronic 8800ml. With its modular design and comprehensive software solutions, it is the ideal electronics for system and component level testing. Its distributed processor architecture provides a clock rate of 10 kHz and guarantees precise results even in the case of highly dynamic tests, irrespective of the number of test channels. The possibility to connect several PCs in various locations allows you to design your lab around your operator’s needs.

Our patented CAN-Bus interface allows the synchronous integration of vehicle control signals and systems to active test specimens so ensuring the integrity of all test parameters. The EtherCAT interface offers a higher bandwidth connection to external devices. With the implemented "distributed clock" technology many EtherCAT devices can now be integrated and synchronized with the test controller. The modular software offers you a wide range of options, which can be enabled by a single license file.

Your investment security is important to us which is why we only use industrial components in our controller design. This means we have a stable robust platform on which to base our software development programs. Through software maintenance contracts, we can guarantee our 8800ml customers will always benefit from the latest versions and functionality over a 10+ year period.

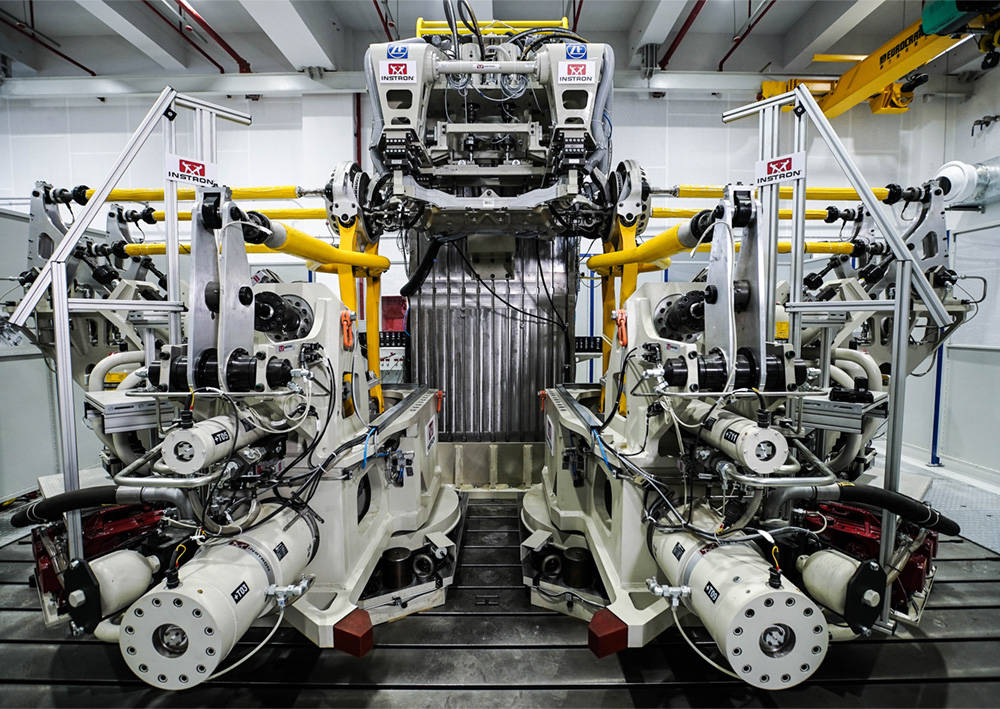

Axle Test System

Axle test rigs are used to reproduce different loads applied to the axle elements when a vehicle is traveling over a variety of road surfaces. Instron can provide models for testing of car, van, truck and bus axles with 6 degree-of-freedom.

Learn MoreComponent Test Systems

Instrons component testing systems are characterized by the highest quality and reliability, ensuring the highest productivity in daily use.

Learn MoreMulti-Axis Shaking Table (MAST)

Multi-axis simulation (MAST) tables are designed for testing of a variety of different specimens in six degrees of freedom. These include components and subassemblies exposed to vibratory loads during vehicle operation; from seats, dashboards and interior equipment components to engine mounts, and cooling modules.

Learn MoreRoad Simulator

HYDROPULS® road simulators are a versatile and cost efficient solution for testing load inputs through the tires. They are used to perform durability tests, as well as acoustic and vibration analyses in testing and development (BSR, NVH) on complete vehicles, subsystems and power train assemblies.

Learn MoreFull Vehicle Test System

Instron offers comprehensive solutions with and without vehicle restraint, with long- or short-stroke introduction of lateral forces as well as the optional environmental simulation with regard to temperature humidity and sun loading.

Learn MoreDynamic Torsion Test System

The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed.

Learn MoreShock Absorber Test Systems

Instron's MSP test system is the ideal tool for reliable, fast and realistic tuning of vehicle chassis designs and development of shock absorber systems.

Learn MoreController Labtronic® 8800ml

Labtronic 8800ml, Instrons new test controller, provides an integrated laboratory solution for all requirements from component tests through to simulation of service loads on full vehicles.

Learn More