Hydropuls® actuators

Challenge

The development of structures and individual components is based on computational life estimation. This is to ensure that the products remain fail-safe within their calculated service life. However, the verification of the computational life estimation is carried out through laboratory testing with realistic simulation of service conditions including displacements, loads and environment.

It is necessary to introduce service loads in a controlled way into materials, components or system modules. The actuators required for this purposes must meet the highest requirements for precision and controllability in order to produce reliable results. Furthermore, these actuators have to be robust and able to operate in a reliable way over many years of operation.

Solution

Hydropuls® linear and rotary actuators convert hydraulic energy into displacements and forces at the test specimen. The actuators are controlled precisely by the 8800ml control electronics and the servo-valve. Hydropuls® actuators can be used in static and dynamic test applications from single axis test machines through to multi-channel test systems.

Hydropuls® actuators are characterized by a number of unique attributes that ensure precise and highly productive operation.

The hydrostatic bearings and the non-contact sealing of the piston rod are unique to the Hydropuls actuator range. As a result, the cylinders are hysteresis-free in quasi-static and dynamic operation over the full displacement and force range. That is free of mechanical seals, friction and wear. This allows continuous operation with minimal downtime and maintenance. The hydrostatic bearing allows the cylinder to react very high transverse loads that often occur in structural testing applications and at specimen failure.

The name Hydropuls® stands for:

- Highest precision and controllability of loadings

- exceptional life and operational safety

- Minimum maintenance

- highest quality "Designed, made and proven in Germany"

Typical applications are:

Hydropuls® Linear Actuator type PL

Hydropuls® linear actuators are powerful and highly dynamic actuators for generating controlled forces, longitudinal movements, velocities or accelerations. The PL standard cylinders cover force ranges from 5 kN to 20 MN. Displacement amplitudes up to +/- 200 mm are available as standard. In addition to 280 bar operating pressure, the cylinders can also be supplied in 210 bar version.

Special cylinders according to customer specifications can be offered on request.

Hydropuls® Longitudinal Actuator Type Minipuls PLF

PLF Minipuls linear actuators are used in the frequency range of 1 Hz up to 1000 Hz. The actuator is capable of producing forces up to 7 kN and is particularly suitable for the precise control of even the smallest force amplitudes in the high frequency range. This actuator is used, for example, in our high-frequency testing machine for the characterization of elastomers.

Hydropuls® Rotary Actuator type PD

Hydropuls® rotary cylinders are used in mechanical tests to initiate controlled quasi-static or dynamic torques or torsional vibrations in material samples or components. The standard series of Hydropuls® rotary actuators offers nominal torques between 0.5 kNm and 64 kNm with rotation angle up to +/- 50 °. Special cylinders with special nominal torques and angular amplitudes can also be supplied on request.

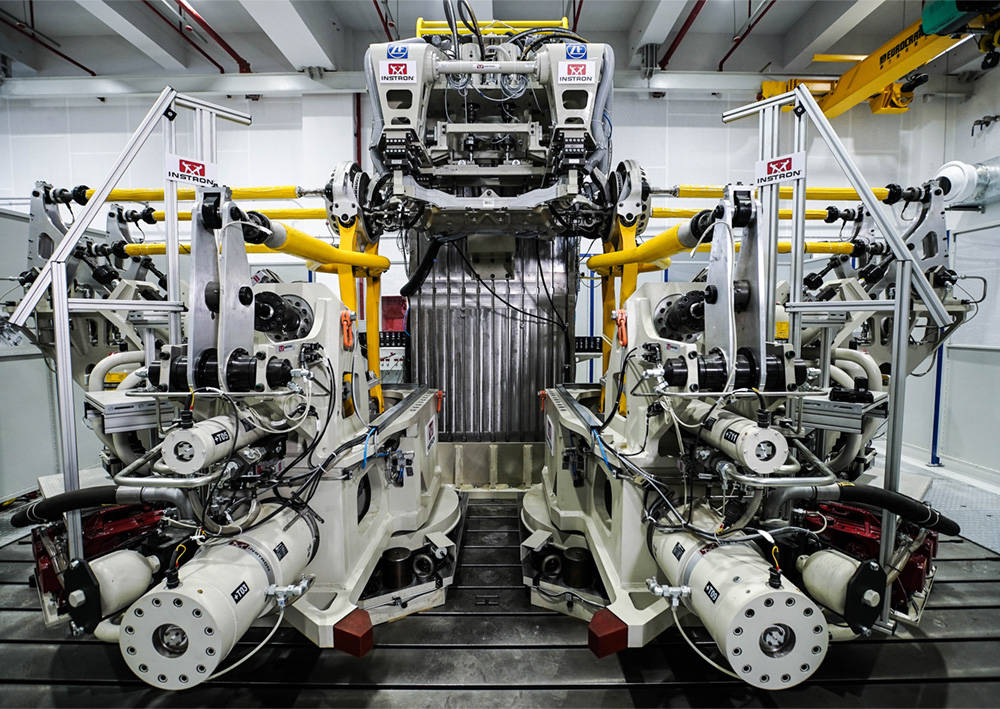

Axle Test System

Axle test rigs are used to reproduce different loads applied to the axle elements when a vehicle is traveling over a variety of road surfaces. Instron can provide models for testing of car, van, truck and bus axles with 6 degree-of-freedom.

Learn MoreComponent Test Systems

Instrons component testing systems are characterized by the highest quality and reliability, ensuring the highest productivity in daily use.

Learn MoreMulti-Axis Shaking Table (MAST)

Multi-axis simulation (MAST) tables are designed for testing of a variety of different specimens in six degrees of freedom. These include components and subassemblies exposed to vibratory loads during vehicle operation; from seats, dashboards and interior equipment components to engine mounts, and cooling modules.

Learn MoreRoad Simulator

HYDROPULS® road simulators are a versatile and cost efficient solution for testing load inputs through the tires. They are used to perform durability tests, as well as acoustic and vibration analyses in testing and development (BSR, NVH) on complete vehicles, subsystems and power train assemblies.

Learn MoreFull Vehicle Test System

Instron offers comprehensive solutions with and without vehicle restraint, with long- or short-stroke introduction of lateral forces as well as the optional environmental simulation with regard to temperature humidity and sun loading.

Learn MoreDynamic Torsion Test System

The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed.

Learn MoreShock Absorber Test Systems

Instron's MSP test system is the ideal tool for reliable, fast and realistic tuning of vehicle chassis designs and development of shock absorber systems.

Learn MoreHydropuls® actuators

Hydropuls hydraulic actuators are used in the full of static and dynamic applications where high precision simulation of movement, forces, strains and accelerations are required.

Learn More