Instron has assisted customers with their materials testing needs for over 75 years. Whether your goals are to prolong the lifespan of your investment, reduce ownership costs, minimize downtimes, enhance your staff’s skills, increase testing precision, accelerate test durations, or hasten your time to market, we possess the necessary resources, equipment, and skilled personnel to collaborate with you in achieving your objectives.

At the heart of our mission lies an unwavering commitment to providing exceptional tailored support and establishing a partnership that prioritizes your needs above all else.

For more than 40 years, Instron® has been providing calibration of the highest quality, offering you a wide range of on-site and factory calibration services for your materials testing systems. All calibrations we provide are traceable to the International System of Units (SI) through a National Metrological Institute (NMI).

Preventative maintenance is essential to sustaining peak efficiency and maximizing the value of your testing system over its lifetime.

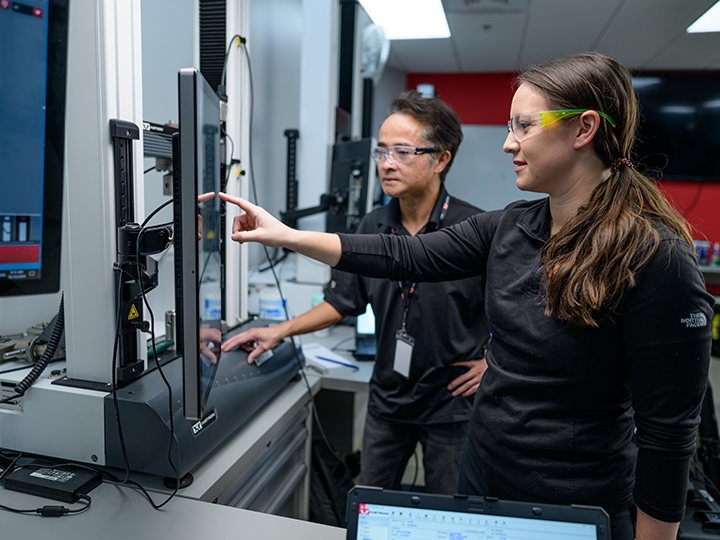

Instron’s Field Service Engineers have access to the latest documentation, official spare parts, and tools required to maintain your equipment at its peak performance.

Our Field Service teams provide validation and documentation services to support IQOQ processes designed to ensure that your Instron testing equipment performs to its intended purposes and produces valid results per 21 CFR 820.72 and ISO 13845.

We understand that when moving your Instron system it’s essential to minimize downtime and keep operations running smoothly. That’s why Instron offers flexible service packages designed to fit your exact needs, whether you require just calibration or a full turnkey relocation solution.

In the event a system repair is needed, our factory-trained Field Service Engineers, backed by dedicated replacement part inventories, stand ready to quickly and efficiently restore the operation of your testing system. We will support your system for as long as it is technically and economically feasible. When appropriate, we can recommend and install upgrades to extend the usefulness of your testing system, significantly lower repair costs, and add new functionality to maximize return on your investment.

Instron’s System Installations, Updates, and Upgrades services ensure your testing equipment operates at peak performance. Whether you’re installing a new system, updating software, or upgrading existing hardware, our experts help you extend the life of your investment while gaining access to the latest functionality and performance enhancements. From improved accuracy and repeatability to compatibility with evolving standards, Instron keeps your lab ready for today’s and tomorrow’s testing demands — all at a fraction of the cost of replacement.

Instron offers a wide variety of training opportunities designed to meet the needs of machine operators and test method developers of all skill levels. Our classes provide in-depth education about materials testing and best practice techniques, in addition to teaching users about the range of testing found in their own particular testing system and its associated software.

The Product Life Cycle Policy is intended to help you plan for the ultimate evolution of your Instron® testing equipment and to provide recommendations on how to move forward. Learn more about our different support options available for each step of the Product Lifecycle or visit the Out of Production section to find out more information.

Instron Service aims to provide the highest quality of service and support for its wide variety of customers, to address their unique needs, and achieve joint success. Learn more from customers who have shared their Instron Service success stories where our high-quality service supported their materials testing needs.