Bluehill® Central Quiz

Bluehill Central 軟體是一種實驗室管理工具,可對與多個 Instron 試驗機台相關聯的 Bluehill Universal 軟體應用程式,進行集中式的遠端管理。透過此軟體,您可以從多個 Instron 系統遠端管理所有 Bluehill Universal 使用者、試驗範本、結果、檔案修訂核准和稽核追蹤資料。

Bluehill Central 使用客戶端/伺服器網路,將所有共用資料、檔案和設定儲存在 Microsoft® SQL Server 資料庫中。當 Bluehill Universal 連接到您實驗室的 Bluehill Central 伺服器時,每個測試系統都會與集中式資料庫進行資料傳送和接收,消除了差異風險和本地管理每個系統的負擔。

|

實驗室 在實驗室中,執行 Bluehill Universal 並連接到您公司網路的電腦可以透過 Central 外掛程式存取 Bluehill Central 資料庫。 |

|

資料中心 由您的 IT 部門管理的資料中心可以託管 SQL Server 資料庫,該資料庫集中儲存 Instron 資料和 Bluehill Server 應用程式,該應用程式處理用戶端和資料庫之間的所有交易。所有用戶端和伺服器都透過您的公司網路連接。 |

|

辦公室 在實驗室外,您可以從 Bluehill Central 檢視器遠端存取檔案和設定。您也可以使用離線 Bluehill Universal 授權來編輯試驗方法和檢視樣本資料。 |

在我們的 實驗室經理和IT管理員指南中瞭解更多資訊。

Bluehill Central 允許將使用者群組組織成共用通用檔案和設定的團隊。操作員的權限和檔案存取權由其團隊定義。這讓您的實驗室能夠靈活地支援不同的工作流程和設定,具體取決於使用該系統的群組。

成員 | 具有個性化權限的個人用戶

試驗系統 | 您實驗室中連接到 Bluehill Central 的 Instron 機台

檔案 | Bluehill 方法、報告範本、PDF 報告或其他 Instron 相關檔案

稽核軌跡 |團隊成員執行的作記錄

設置 |安全類型、文件審批和其他團隊級別設置

實驗室管理模組包含儲存在資料庫伺服器上的 Bluehill Central 檔案儲存庫。連接的 Instron 試驗機可以存取資料庫以執行受控測試方法或匯出結果。

![]()

![]()

![]()

![]()

Bluehill Central 中的可追溯性模組允許您遠端審查並以電子方式簽署測試方法修改、樣本資料以及在 Instron 系統上發生的其他 Bluehill 檔案變更。檔案核准和 Bluehill Central 及 Bluehill Universal 中的許多其他使用者操作都會自動記錄在集中式稽核追蹤中,以驗證在任何連接的 Instron 系統上誰做了什麼、何時做的以及為什麼做。注意:可追溯性模組顯示來自具有可追溯性 + 實驗室管理(Central 外掛程式)的 Instron 系統的資料,這是 Bluehill Universal 的附加元件。

![]()

![]()

![]()

瞭解 Bluehill Central 中的可追溯性如何與 Bluehill Universal 中的標準安全性和本機可追溯性進行比較。

瞭解 Bluehill Central 中的可追溯性如何協助您滿足 FDA 21 CFR Part 11 的技術要求。

Bluehill Central 中的 TrendTracker 模組可加速您實驗室的資料分析工作流程。直覺的介面讓您能夠快速搜尋、顯示和分析跨多個樣本和測試系統的長期結果。告別繁瑣的檔案搜尋和資料複製貼上工作。

多樣品資料分析

對來自多個測試系統產生的多樣品的結果執行資料分析。

客製化查詢

建立由測試參數或結果定義的查詢,提供趨勢和異常值的見解。

視覺繪圖

繪製各種圖表類型以可視化數據集。

匯出資料

將資料匯出到 CSV 檔案,並在應用程式 (例如 Minitab®) 中開啟以進行進一步分析。

了解有關 TrendTracker 中可用的統計數據和圖表的更多資訊。

瞭解 TrendTracker 如何使您能夠更快地做出數據驅動的決策。

快速流覽 TrendTracker,瞭解設置、監控趨勢和發現洞察有多麼容易。

以下是 Bluehill Universal 材料測試軟體中所有可用的預設測試方法清單。

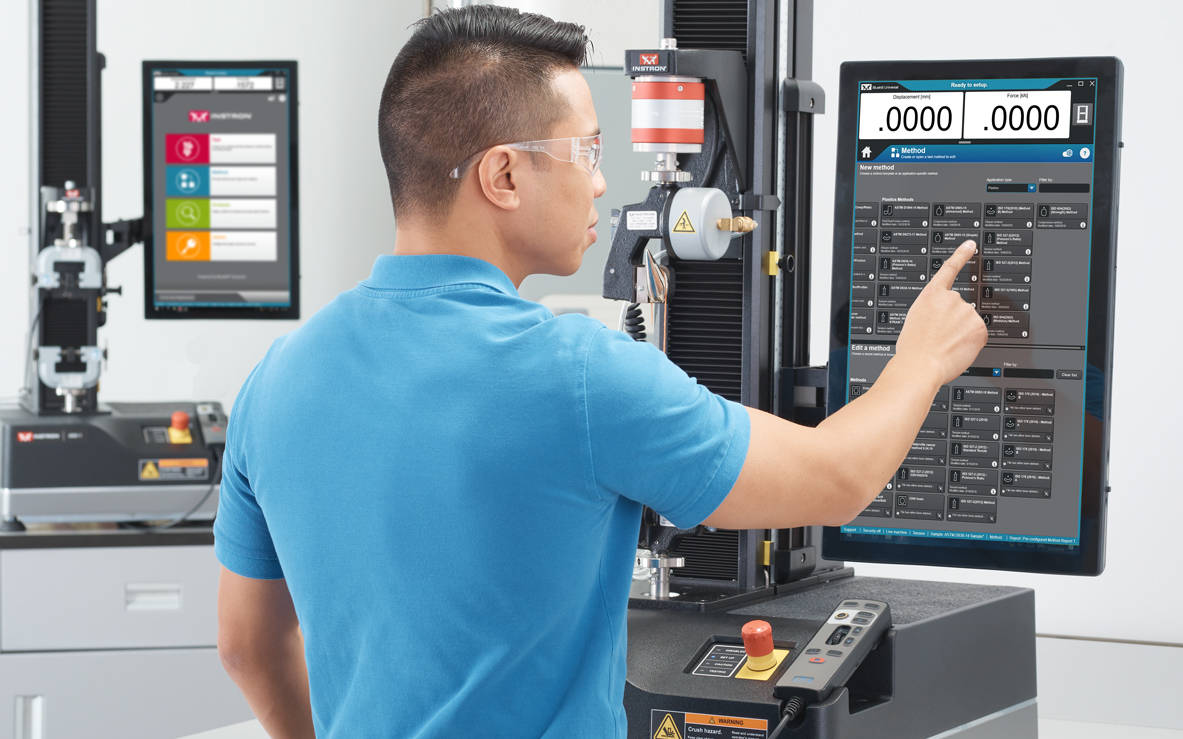

新一代的材料測試軟體

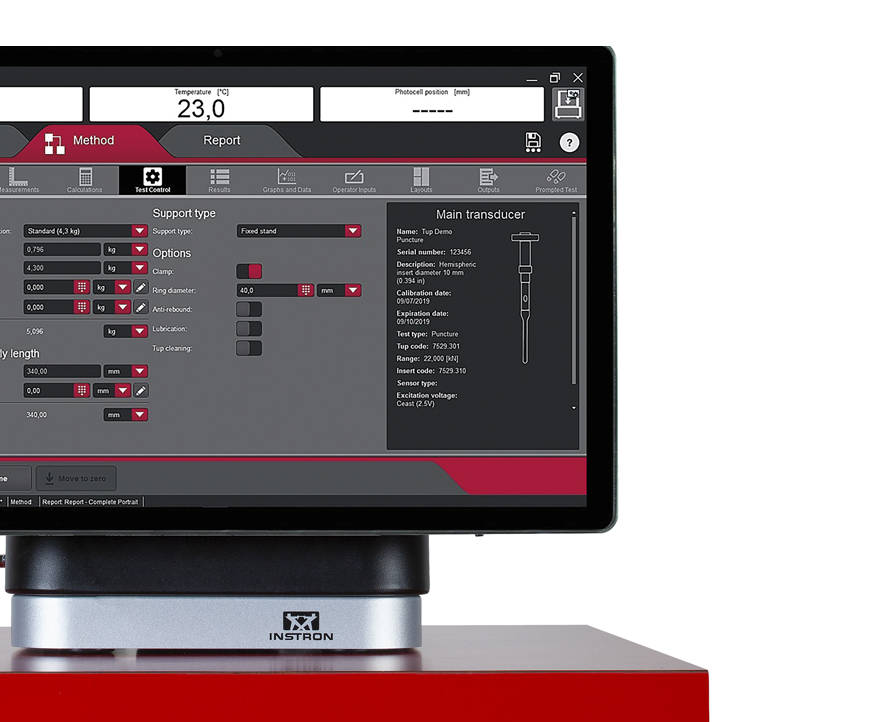

Bluehill Universal 是專為觸控互動而設計。全新的直立式版面,搭配精心打造的視覺設計,使操作面板擁有最完備的測試工作區畫面,帶來令人驚豔的大尺寸觸控螢幕以及內建控制器。直覺式工作流程讓訓練新手或老手都變得輕鬆、簡化操作員的訓練,而且讓您的測試速度變得比以前更快。

操作面板功能具備大型觸控點以及易於理解的圖示,提供更簡單、更聰明的使用體驗。Operator Dashboard 設計以人體工學為出發點,採用放大顯示的一體化電腦與觸控螢幕,可掛放在使用者的 Instron 系統側面,或搭配托架基座使用。

快速測試

當您需要快速取得結果時,QuickTest 讓使用者只需輸入幾個簡單參數,就能在數秒內執行測試。

方法範本

Bluehill Universal 包含一個預先設定的測試方法資料庫,符合一些最常用的 ASTM、ISO、EN 和其他標準。

提示測試

透過逐步指示引導使用者完成整個測試程序,以確保測試是可重複、簡單而且無錯誤。

整合試片量測

直接將測微計和卡尺連結系統,即可輕鬆匯入試片尺寸,以進行應力量測。

通過/失敗

可讓使用者將測試部件新增到工作區中,以根據測試方法中設定的可接受範圍,快速呈現測試結果是通過還是失敗。

條碼掃描器

使用者可透過任何 USB 條碼掃描器,順暢地將資訊輸入 Bluehill Universal 中。只要建立一個條碼(包括標籤功能),便可在任何文字或數字輸入欄位中新增資訊。

簡單操作並不代表您必須放棄進階的功能。Bluehill Universal 的模組化功能帶來強大的功能和靈活性,方便您執行最複雜的測試。

運算式生成器

使用一組變數、量測值和原始資料建立您自己的自訂功能。例如,使用者可將測試速度設為試片寬度和厚度的函數,或是建立自訂原始資料運算式,例如在流體槽中測試時減去阻力。

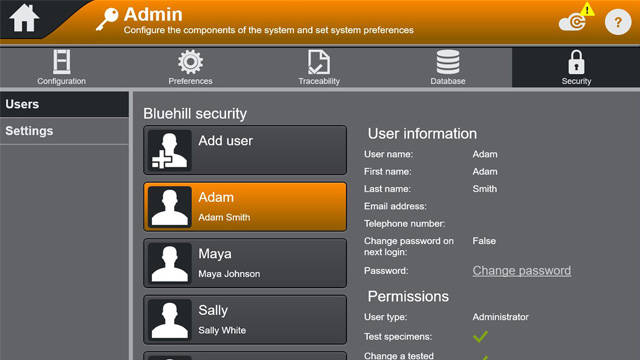

保安

Bluehill Security 可讓實驗室主管在軟體中配置權限,授與存取權給受過訓練的人員(如超級使用者),並在需要時限制存取權限。Bluehill 安全允許您直接在 Bluehill 中配置登入權限,或是連結到本機 Windows 登入或 Windows Active Directory。

追蹤功能模組

Bluehill Universal 的追蹤功能模組可讓使用者符合與 FDA 21 CFR 第 11 部分, ISO 17025、Nadcap 等規範相關的稽核要求。透過無縫整合電子核准、修訂歷程記錄,以及自動化稽核軌跡,此功能強大的附加元件結合 Bluehill 的內建安全性,提供無人能及的資料可追溯性。

(選用工作量)

手冊

功能比較:標準安全性 vs. 可追溯性(本機)vs. 可追溯性(Bluehill Central)

FDA 21 CFR 第 11部分「施行白皮書」

數據完整性和 Bluehill 可追溯性 |創建一個更高效的實驗室

網路研討會:Bluehill Universal 可追溯性模組介紹

資料庫類型

可追溯性數據檢查提供網路與本機資料庫功能,能夠因應您的資料管理偏好。支援網路連線的集中管理資料庫,為您的實驗室提供更優異的效率,與在本機管理的資料相比更能降低風險。在考慮這些替代選項時,建議先判斷您的實驗室 IT 基礎建設與資料管理偏好。

Bluehill Universal 的本機可追溯性模組將數據追蹤資料儲存在 Microsoft SQL Express 資料庫中,而該資料庫的主機位於執行與 Instron 系統連線的 Bluehill Universal 電腦上。本機資料庫模型適用於無法將電腦連線到共享網路的實驗室。在電腦本機上檢視數據追蹤資料以及電子簽署檔案,而每一個搭載本機可追溯性資料庫的 Instron 系統都會儲存自己的 SQL Express 資料庫。資料庫備份與還原功能可在 Bluehill Universal 手動執行。

Instron 可追溯性的網路解決方案由 Bluehill Central, 提供技術支援,在 Microsoft SQL 伺服器上部署客戶端/伺服器架構來儲存所有共享的數據追蹤資料、檔案以及設定。當 Bluehill Universal 連線到您的實驗室的 Bluehill Central 伺服器時,每一個測試系統都會從集中管理的資料庫中傳送並接收檔案,降低變數的風險以及在本地管理各個系統的負擔。可在 Bluehill Central 中遠端執行或在 Bluehill Universal 中以本機檢視數據追蹤資料、電子簽署檔案、以及使用者管理。資料庫備份與還原功能可在 Bluehill Central 手動執行。

分析

無需重新執行測試,即可重播、重新分析或修改先前測試過的試片。

(選用工作量)

TestCam

連接 USB 網路攝影機,以體驗逐點影片播放,如此即使在測試完成後,您仍能檢視測試。

(選用工作量)

子樣本

使用子樣本,使用者便能依據所有參數對結果進行排序,包括操作員姓名、試片斷裂位置和特定試片性質。

TrendTracker 測試結果管理軟體

直接將結果匯出到 TrendTracker 資料庫。使用者可以在 Bluehill Universal 中建立多個資料庫連線,然後在適當的方法中選擇 TrendTracker 資料庫。

(選用工作量)

應用程式設計介面

Bluehill Universal 的應用程式設計介面 (API) 可讓系統管理員編製自己的自訂介面,以便在 Bluehill 內控制測試前後的動作。在許多情況下,API 都可讓您於測試序列的部分環節自動化,還能建立您自己的介面,以便執行系統的特定功能,例如匯入、開始或匯出。

離線授權

某些使用者習慣在自己的辦公桌或是在自己的筆記型電腦上從遠端建立方法或測試後資料分析。「離線程式設計與資料分析」選項以單一授權或無限授權的形式提供。

內建於 Bluehill Universal 的 Instron Connect,運用物聯網 (IoT) 為顧客帶來更快速、更精簡的技術支援。Instron 努力成為顧客滿意度的領導品牌,而 Instron Connect 能夠讓我們的支援工程師更貼近企業用戶。

相容性

新型 6800 與 3400 系統透過操作面板提供 Bluehill Universal。除了升級到 5900 電子設備的系統之外,您還可以將它新增到現有的 6800、3400、5900、3300、5500、59R 和 IS02 等靜態測試系統。ElectroPuls™ 和 8800 動態系統在執行靜態測試時,也可以利用 Bluehill Universal 的多功能和簡單易用的特性。

訓練 | 電腦需求 | Bluehill SQA 信函

CrashSim Office是一款独立的程序,用于信号准备和处理,以及预测波形生成能力和生成适用于碰撞模拟系统的驱动信号。CrashSimOffice脱机用于碰撞模拟系统,主要具有以下特征

导入功能

编辑功能

预测功能

CrashSim Office是现代软件开发过程中不可或缺的工具。由于可变因素较多,该程序免除了滑台试验操作中大量必要的预发射,以证明波形的可行性。因此,CrashSim Office能帮助滑台系统更有效、更高效率地运行。

深入了解碰撞模拟系统.

以下是安裝和正確操作您系統上的 Bluehill® Universal 測試軟體所需的最低電腦需求。其他需求取決於附加裝置,例如影像引伸計。請聯絡我們以取得建議的配置。

Bluehill Universal 專為觸控互動而設計,因此建議使用觸控螢幕顯示器以獲得最佳使用者體驗。

其他需求取決於附加模組,例如影像引伸計。請聯絡我們以取得建議的配置。

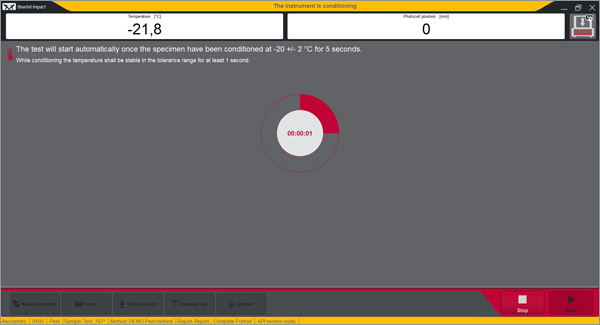

Bluehill Impact for Pendulum has been designed to meet customer needs. The touchscreen interface features an outstanding visual design that improves user experience while also incorporating safety features. Intuitive workflows make it easy to train users, simplify operator training, and allow you to start testing faster than ever before.

![]()

CLICK TO PLAY TESTING

Pre-configured methods are already provided. You can select a suitable method, and press start immediately.

![]()

ENHANCED SAFETY

The color-coded framework informs you about the machine's status and provides clear, valuable information to the user. A simple glance lets you know what environment you are in, and whether it is safe to interact with the machine.

![]()

ADVANCED CALCULATION

Automatic identification of break type from the shape of the curve in accordance with ISO 179-2.

![]()

USER-DEFINED ACCESS RIGHTS

With three different pre-defined profiles to select from, it is possible to configure the workspace to suit the needs of different users and limit the functionality that is available to an individual.

Pendulum Impact Testing Machine enables users to determine the impact resilience of plastics and composites, easily and safely.

Bluehill Fracture Standards Library is a Microsoft Windows PC compatible software package, developed by Instron - Division of ITW Limited, that provides a library of analysis functionality used by the Instron Bluehill Fracture software.

|

Analysis Result

|

Measurement

|

Specimen

|

|||||||||||||

|

KIc

|

KIsi

|

CTODc

|

Jc

|

JIc

|

Clip-Gauge

|

DCPD

|

C(T) Straight Notch

|

C(T) Load Line

|

SEN(B)

|

Disc Straight Notch

|

Disc Load Line

|

Arc Tension

|

Arc Bend

|

M(T)

|

|

|

ASTM E399-23

|

✔ | ✔ | ✘ | ✘ | ✘ | ✔ | ✘ | ✔ | ✔ | ✔ | ✔ | ✘ | ✔ | ✔ | ✘ |

|

ASTM E1820-24

|

✘ | ✘ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ✔ | ✔ | ✘ | ✔ | ✘ | ✘ | ✘ |

|

ISO 12135:2021

|

✔ | ✘ | ✔ | ✔ | ✔ | ✔ | ✘ | ✔ | ✔ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ |

|

GB/T 21143-2014

|

✔ | ✘ | ✔ | ✔ | ✔ | ✔ | ✘ | ✔ | ✔ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ |

|

BS 7448-1:1991*

|

✔ | ✘ | ✔ | ✔ | ✘ | ✔ | ✘ | ✔ | ✔ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ |

|

ASTM E647-19

|

✘ | ✘ | ✘ | ✘ | ✘ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

ISO 12108:2019

|

✘ | ✘ | ✘ | ✘ | ✘ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

Brittle KIc

|

Brittle/Basic CTOD or J

|

Ductile JIc (single specimen)

|

Ductile JIc (DCPD)

|

Crack Growth

*Excludes post-test analysis

|

||||

|

Standards →

|

ASTM E399-23

|

ISO 12135:2021

(GB/T 21143-2014)

|

ASTM E1820-24

|

ISO 12135:2021

(GB/T 21143-2014)

|

ASTM E1820-24

|

ISO 12135:2021

(GB/T 21143-2014)

|

ASTM E1820-24

|

ASTM E647-19

ISO 12108:2018 (GB/T 6398-2017)

|

|

Specimens ↓

|

||||||||

|

C(T) Straight Notch

|

✔ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ |

|

C(T) Load Line

|

✘ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

SEN(B)

|

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

Disc Straight Notch

|

✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ |

|

Disc Load Line

|

✘ | ✘ | ✔ | ✘ | ✔ | ✘ | ✘ | ✔ |

|

Arc Tension

|

✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ |

|

Arc Bend

|

✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ |

|

M(T)

|

✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ |

Version 2.4 Build 24093.01 (16/September/2024)

Version 2.3 Build 24093.01 (19/April/2024)

Version 2.2 Build 23335.3 (16/January/2024)

Version 2.0 Build 22018.01 (18/January/2022)

Version 1.3 (20/May/2021)

Version 1.2 Build 20167 (23/Jun/2020)

Version 1.2 Build 20063 (10/Mar/2020)

Version 1.1 (07/Nov/2019)

Version 1.0 (04/Feb/2019)

注意:下面顯示的功能清單旨在突出每個軟體版本版本中包含的重要增強功能。有關按版本劃分的增強功能和修改的完整清單,請參閱 Bluehill Universal 發行說明,該說明存儲在Instron資料夾中,可從Windows開始訪問。如果尚未安裝 Bluehill Universal , 請聯繫我們 索取發行說明。

於 2025 年 8 月發布

發佈時間:2025年6月

發佈時間:2024 年 7 月

發佈時間:2023年1月

發佈時間:2022 年 8 月

發佈時間:2022 年 4 月

發佈時間:2021年12月

發佈時間:2021年5月

發佈時間:2020 年 12 月

發佈時間:2020 年 6 月

發佈時間:2020 年 2 月

發佈時間:2019 年 6 月

發佈時間:2018 年 12 月Released December 2018

發佈時間:2018 年 6 月

發佈時間:2017年11月

發佈時間:2017 年 8 月

發佈時間:2017年2月

注意:下方顯示的功能清單旨在強調每個軟體版本發佈中包含的重要增強功能。如需每個版本的完整增強功能和修改清單,請參閱 Bluehill Central 發行說明,該說明儲存在可從 Windows「開始」存取的 Instron 資料夾中。如果尚未安裝 Bluehill Central,請聯絡我們以索取發行說明。

於 2025 年 8 月發布

2024 年 11 月發布

發佈時間:2024 年 7 月

2022 年 12 月發布

發佈時間:2022 年 4 月

發佈時間:2021年12月

|

|

|

|

|

FEATURE

|

WAVEMATRIX3

|

WAVEMATRIX2

|

WAVEMATRIX

|

| 直覺的使用者介面 | ✓ | ||

| 回顧性測試審查 | ✓ | ||

| 自動校正 | ✓ | ✓ | ✓ |

| 基於剛性調校 | ✓ | ✓ | ✓ |

| 快速測試設定 | ✓ | ✓ | |

| 可自訂的樣本和測試詳細信息 | ✓ | ||

| 整合虛擬測試訊息 | ✓ | ||

| 試片保護 | ✓ | ✓ | ✓ |

| 範例方法 | ✓ | ✓ | |

| 影片教學 | ✓ | ✓ | |

| PIN 碼輔助功能 | ✓ | ||

| 使用者定義的存取權限 | ✓ | ||

| 視覺測試空間 | ✓ | ✓ | ✓ |

| 直覺的測試設置 | ✓ | ✓ | |

| 視覺序列產生器 | ✓ | ✓ | ✓ |

| 微軟 Windows 11 兼容性 | ✓ | ✓ | |

| WaveMatrix 向後兼容性 | ✓ | ||

| 始終置頂顯示 | ✓ | ✓ | ✓ |

| 自動記錄 | ✓ | ✓ | ✓ |

| 強大的文件結構 | ✓ | ✓ | ✓ |

資訊科技相容性 | 面向未來的設施

隨著世界進入第四次工業革命,材料測試產業對自動化和數據交換的需求不斷增加。 軟體通常用於解決這項挑戰,WaveMatrix3的設計就是為了應對這些挑戰並確保測試機構盡可能面向未來。

Provides system control, data acquisition, real-time graphs, calculation of results, storage of data to disk, and post test graphs and reports in accordance with the relevant sections of ASTM E606-04, BS 7270 (2006), and ISO 12106 (2003).

Please contact Instron for the minimum PC requirements necessary to install and operate this software.

RS LabSite® modulogic is a comprehensive and adaptable software suite conceived for introducing service loads into individual components or complete vehicles, or performing calculations within the framework of Virtual Prototyping (standardized loadsequences, virtual generation of load data). This enables you to stay in full control of all tasks that follow the acquisition of measurement data in the proving ground.

In addition RS LabSite® modulogic provides open and closed loop control functions for your durability tests, collects data and monitors the entire process. Extensive reporting functions with graphical presentation of results – programmable to suit your requirements – round off the package.

The software is modular and consists of four components. The basic module, RS BasTest RT, provides all necessary tools for digital pre-processing of durability tests. Depending on requirements, the extension modules RS Analysis, RS TWR and RS Monitoring, can be used for single- and multi-axial service load simulations, specific analysis procedures or multistage reporting functions. The software runs under the Windows© operating system.

RS LabSite® modulogic is an integrated and modular solution for analysis of test rig data and test execution:

| Item Name | Cat# |

|---|---|

| RS MePar ml | RS MePar ml |

| RS BasTest RT | RS BasTest RT |

| RS Monitoring | RS Monitoring |

| RS TWR | RS TWR |

| RS Analysis | RS Analysis |

To enable the different loading signals measured under actual service conditions on vehicles, sub-assemblies or components to be replayed on the test rig, these loading signals first need to be "translated". RS TWR (Time Waveform Replication) produces a mathematical model of the test specimen and the test rig, and uses this model to calculate actuator drive signals from measured load histories, e.g. loads or strains. The system employs an iterative procedure and ensures maximum accuracy in the reproduction of measured load data.

The module excels through user-friendly operation. Assisted by the new integrated process flow tool, less experienced operators will be able after a very short period of familiarization to conduct a typical simulation procedure. The Windows environment will be familiar to most users, and an intelligent selection of parameters minimizes necessary user inputs.

在线监控试样测试或快速简单地分析测量值,如今已不再是足够便捷的功能:市场竞争日益激烈,“产品投入市场的时间 ”需要不断缩短,因此,产品试验效率亟待提升。RS Monitoring 功能强大,可助您更快实现上述目标。该模块可在试验过程中计算监测统计变量和物理变量,并通过雨流计数法记录整体损害。该功能能够让您在早期阶段检测到试样的行为变化,并采取相应的应对措施。这个模块来自RS LabSite®模块化软件组拥有大量十分有用的计算功能。可享用以下优势:

The effect of temperature on the mechanical properties of plastic materials has a fundamental role in the design of components, especially in the selection of materials. Unlike metals and ceramics, plastics are extremely sensitive to the slightest changes in temperature. The selection of plastics for applications under different temperatures is a complex task. The material must be able to support a stress under operating conditions without losing its strength and without critical distortion. The effect of temperature on geometrical stability and mechanical properties in general can be studied following different procedures and methods like at constant temperature or with a temperature ramp.

Bluehill HV is the generation software for HDT and Vicat tests

RSAnalysis is an important tool throughout the data acquisition and handling process. Dedicated algorithms condense and optimize your measurement data and turn them into loading data that simulates a complete product life circle. This module from the RS LabSite® modulogic SoftwareSuite provides for analysis and graphical presentation of test data, while allowing maximum freedom: Apart from the presentation of measured data, a wealth of other functions are available for performing typical data analysis procedures quickly and systematically.

If the numerous standard reports integrated in the software do not meet your requirements, customized formats can be created as required. This makes sure that you are aware at all times how your tests are running and what results they are producing.

RS Analysis is available in two versions: Choose either the Basic- or the Advanced-versions in accordance with your specific needs. Whichever version you choose, the following benefits will be at your disposal:

Low-Cycle Fatigue 3 Software offers a flexible workspace designed to run and analyze strain-controlled fatigue tests in accordance with ASTM, ISO, and BS Standards.

A range of pre-configured graph and results fields allow real time views of how the test is progressing. Customize the screen to display up to three graphs of cycle and trend data. Pause and re-start the test at any time, checking modulus as desired.

Whether you need a single or multiple graphs, the graphing toolbox allows users to clearly display X-Y and double-Y graphs, and peak and trend data charts. Choose to show titles, add legends or show actual data points on a grid. LCF3’s graphing capability is second to none.

Analyze post-test data off-line, selecting from a range of single cycle and trend plots. Overlay individually selected hysteresis loops. Export individual graphics in JPEG format, and data as TXT files.

Start, stop, and finish a test. The simple test control buttons are consistently at the right side of the screen. For added convenience, a test can be paused and continued when desired.

Recall recently used test methods or simply browse the method folder to create or edit existing test methods. Test method creation is available off-line, maximizing testing machine availability. With a unique step-by-step data entry and test selection process, combined with a tabulated pre-test summary, your Low-Cycle Fatigue test will run successfully each time.

Select rectangular, cylindrical or tubular geometries, and automatically re-calculate the cross sectional area.

Ensure your modulus data is accurate by utilizing the user-defined upper and lower calculation points, with clear graphical references.

Control the test’s start temperature, soak period, and allowable thermal tolerances from within the application, and log temperature data directly into the test file.

Configure the combined linear, logarithmic and peak internal data logging parameters to suit your test requirements.

Bluehill Elements 軟體採用 Bluehill 平台為基礎,符合簡單的拉伸、壓縮、撓曲、剝離和撕裂測試需求。Bluehill Elements 具有諸如自動生成報告、提示測試工作流程、即時控制圖表等功能,以及善用 TrendTracker 資料庫的選項,特別適用於品質管制測試。

自動資料匯出

使用者可將測試結果和原始資料匯出成 CSV 或自訂文字檔。匯出格式完全可自訂,讓使用者能夠輕鬆擷取資料或與實驗室管理系統交流互動。

原始資料檢視功能

直接從軟體檢查任意量測的每個數據點。

操作員無需以手動方式輸入數據

自動從量測裝置輸入試片尺寸、掃描條碼以便將編號和文字輸入到軟體中,或是利用選擇輸入為使用者提供簡單的下拉式選單,省去手動輸入資料的麻煩。

賞心悅目的顯示畫面

測試狀態、量測和主要測試結果都會顯示在方便讀取的即時顯示畫面上。

直覺式操作,使培訓需求降至最低

Instron 瞭解勞動力變化的事實,因此我們選擇以最低的培訓需求作為易用性的關鍵指標。Bluehill Elements 軟體具有簡單、使用方便的介面。

準確的報告給正確的對象

Bluehill Elements 整合幾種預先定義的報告範本,可輸出至印表機、電子郵件,或是直接將檔案儲存成可輕鬆分享的 PDF 檔。利用預填選項,即可輕鬆更改曲線圖的位置並設定表格。使用者可將特定報告範本連結到指定的方法,以針對不同測試自動產生報告。

基本安全性

在生產與品質管制測試中,一般測試人員不應有權存取方法及變更參數;針對這類測試,Bluehill Elements 備有三種可配置的安全性等級:系統管理員、管理者和操作員。

共同語言

在測試領域裡,Bluehill 是一套標準工具。Bluehill 提供 15 種語言版本並已在全球成千上萬的系統中使用,其測試方法、計算和資料格式已獲普遍認可及接受。不論您要與當地供應商核對資料,還是與跨國客戶比較測試方法,Bluehill Elements 都能讓您使用共同語言來溝通。

TestCam

連接 USB 網路攝影機,以體驗逐點影片播放,如此即使在測試完成後,使用者仍可一面觀看影片,一面檢視測試資料。

通過/失敗部件

為多個測試結果設置接受標準。如果其中一項結果高於或低於可接受範圍,Bluehill Elements 將自動顯示代表「通過」綠色打勾圖示,或是代表「失敗」的紅色畫叉圖示。

TrendTracker 測試結果管理軟體

Bluehill Elements 的 TrendTracker 選配軟體可讓使用者直接將結果匯出到 TrendTracker 資料庫。TrendTracker Viewer 提供一個直覺式介面,用於搜尋、顯示及分析長期測試結果。

需要 Windows 10或 11,64 位元作業系統。Bluehill Elements 可搭配使用觸控螢幕。

Bluehill Elements™ 以 Bluehill® 軟體平台為基礎,符合簡單的拉伸、壓縮、撓曲、剝離和撕裂測試需求。Bluehill Elements 具有諸如自動產生報告、提示測試工作流程、即時控制圖表等功能,以及善用 TrendTracker 資料庫的選項,特別適用於品質管制測試。

DIC is an optical technique that compares images of a tested specimen’s surface to generate full field strain and displacement maps. It creates pictures that can be used to visualize strain and displacement over the full two dimensional surface of the test specimen.

DIC Replay Software is a self-contained 2D DIC package. The software consumes images and calibration data saved by the Instron® Advanced Video Extensometer (AVE) and works in a post-processing mode. The user interface leverages the same tabbed style and graphical design of Bluehill®.

Standard features include:

Benefits:

Instron DIC Replay Software is a 2D digital image correlation package that works seamlessly with the AVE 2 Advanced Video Extensometer. Use this package to visualize strain and displacement over the full surface of a two dimensional object or create simple line plots from virtual strain gauges and extensometers.

应用软件CrashSim用于在Instron台车系统上进行的碰撞试验的准备、执行、监控、分析和记录。通过与全球用户群体的合作,我们对这一聚焦于用户应用的软件进行了持续不断的升级。

使用CrashSim不需要具备专门的知识,软件操作直观,易于理解。用户界面符合Windows7标准。

以下应用所需的参数设置和阀门配置存储在控制系统中,并且在选择测试方法时由CrashSim自动设置:

得益于这一高度自动化,确保了测试操作的高产和高效。

基础版本的CrashSim 5.0具备以下功能:

高级版本的CrashSim 5.1包括了Instron开发的最新迭代模型,这大大减少了所需的迭代次数。该版本还包括CrashSim Office软件模块。该模块允许对测试脉冲进行外部处理,直到产生台车系统的驱动信号。 以前,波形预测只能通过在系统上试打来实现,而现在则可以通过CrashSim Office软件进行离线操作来实现。 。这减轻了此类任务的日常测试操作,提高了系统的工作效率。

了解有关碰撞模拟系统的更多信息.

RS BasTest provides a wide range of functions for editing, performing and conducting durability tests. Project Manager will guide you through all processes. It is used to create new projects, and its integrated data base collects and manages all measurement data. If you are envisaging a future extension of your testing environment, you will be ideally set up with RS BasTest: Other modules from the RS LabSite® modulogic family can be integrated into the system without any further intervention. The basic module will assist you with a high degree of flexibilty and provide the following benefits:

Compatible with WaveMatrix, LCF3, Bluehill 2 and Fracture Mechanics (da/dN, K1C & J1C)

Please contact Instron for the minimum PC requirements necessary to install and operate this software.

RS MePar ml 是 RS LabSite 模块化软件组的一个模块,与 RS Studio ml 和 RS BasTest RT(RS LabSite 模块化的基础模块)配套使用,可用于确定具有粘弹性部件的特性。RS MePar ml 可用于创建简单的单轴试验或复杂的多轴试验。

灵活的试验监控和数据采集功能可确保试验工程师拥有所需信息,从而精确指出进行试验的部件。此外,MePar Viewer 的整合数据不仅能使装置中产生的试验数据可视化,还能以多种图表进行展示。使用该工具,可直接在屏幕上观察到试验结果。

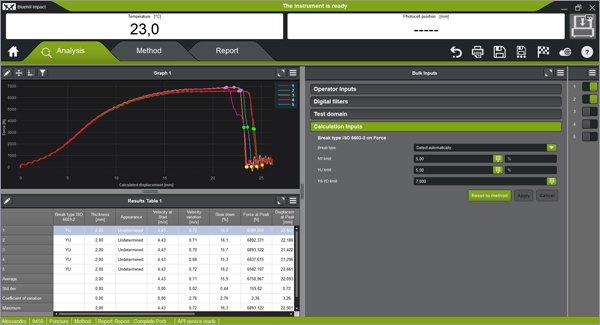

Bluehill Impact is built from the ground up for touch interaction. The Operator Dashboard features large touchpoints to make the user experience simpler and smarter. Easy-to-understand icons and workflows make it easy to train new or experienced users, simplify operator training, and allow you to start testing even faster than ever before.

SIMPLER

Effortless Drop Weight Impact Testing Workflows

Bluehill Impact provides a set of pre-configured defaults that cover the most common impact testing scenarios.

Users can define unique data flow and procedures ensuring data processing flexibility. Bluehill Impact reports on anomalies and inconsistent results when they are outside set parameters.

Thanks to prompted tests and the touch panel, procedures set up takes just a few clicks. Users can be guided through the entire testing process with step-by-step instructions, ensuring that their tests remain repeatable, simple, and error-free. The prompts are customizable with your own text messages.

Increased productivity thanks to the combination of the new Dashboard with data acquisition system and Bluehill Impact.

Move from task to task: easily share test method and results within your Company or your Customers with Bluehill Impact file management system.

Specimen Multi Selection

Edit parameters for many specimens at the same time with one click.

Break Type Recognition

Automatic recognition of the break type according to the shape of the curve (ISO 6603-2). This ensures associations to the break type remain the same operator-to-operator.

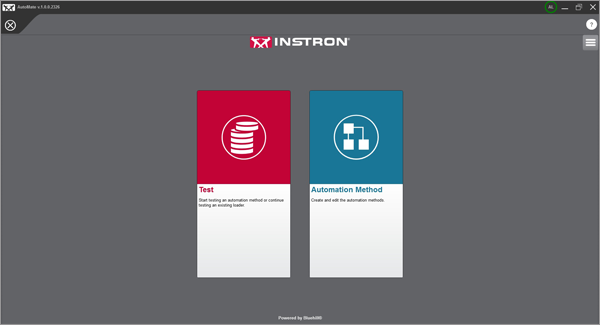

Automatic Testing

Once a test method has been created in Bluehill Impact, you can use AutoMate Software module to customize how the specimens in the automatic feeder are tested, assigning different test velocities and temperatures.

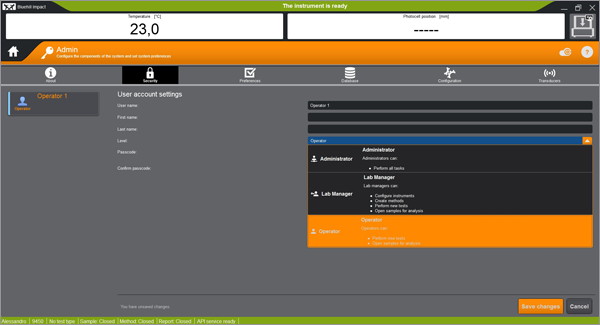

Secure Access

Bluehill Impact security allows the Lab manager to configure permissions granting full access to super users and limiting access where needed.

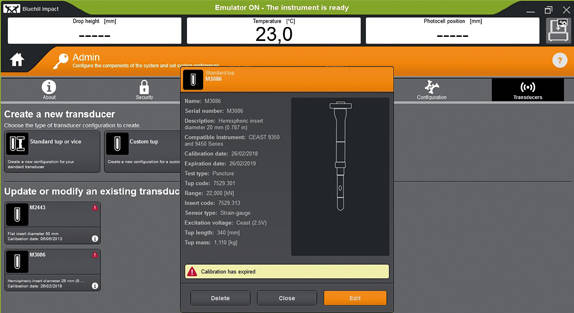

Tups Calibration Alert

Automatic alerts are generated when Tup calibration period is expiring. This feature helps to reduce the risk of invalid tests and protect your results against inaccuracies.

Built-In Safety Notifications

The Dashboard gives clear visual information on the instrument status, so users always know when a test is in progress.

REMOTE TECHNICAL SUPPORT (RTS)

HAVE AN OLDER SOFTWARE VERSION?

Learn About Upgrading your Drop Weight Impact Testing Software

Bluehill Impact & Dashboard with Data Acquisition System

The state-of-the-art controller can be retrofitted on all the 9340 with Firmware version later than 1.00 and on all the 9350 Drop Weight Impact Testing Machines with FW version later than 3.00, including machines with automatic feeding option.

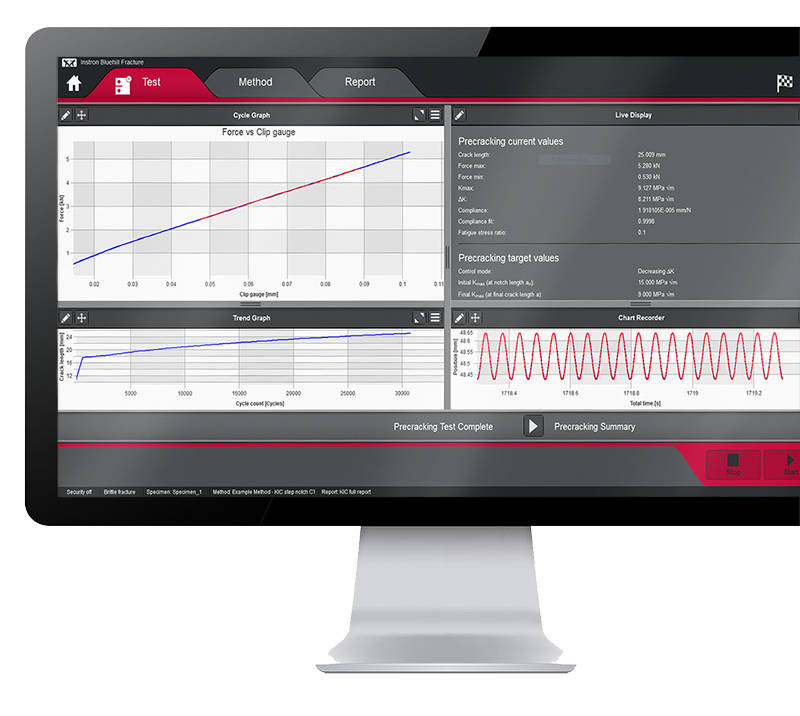

Simplify your Fracture Testing, Analysis and Reporting

Bluehill Fracture is a dedicated fracture mechanics software from Instron. Machine control, data analysis and reporting are performed for metals fracture toughness measurement to key international standards.

As a leading supplier of testing equipment for crack propagation and fracture toughness, Instron are aware of the challenges users face in reducing both the complexity and time taken to produce accurate, repeatable results. The Bluehill Fracture software package addresses these challenges.

Customizable test flows guide the user through the steps needed to produce their final results, saving time by minimizing data entry at each step.

Comprehensive on-screen user guidance along with automatic post-test analysis and reporting tools also reduce the skills and training required. Additionally, the layout, terminology and test progression is common to other Instron software packages, such as Bluehill Universal.

For the latest technology now available with Bluehill Fracture DCPD software, click below to upgrade today.

Method Definition

Bluehill Fracture's unique test workflow definition breaks the test into a logical series of steps, enabling the test designer to control the process of data entry before, during and after the test.

A reduction in entering the same data for each test saves time and minimizes data entry errors. Parameters for each stage can either be pre-populated prior to the test, imported automatically from a LIMS system or entered manually every time a test is run.

SMARTER

Produce results faster

Although Bluehill Fracture is simple to use, there are still many advanced features for analysis and report generation.

Run and Analyse Tests

Performing and analyzing Fracture Toughness tests has never been simpler than with Bluehill Fracture.

Select a test method to run, from a pre-defined list or your own customized method, and Bluehill Fracture will step you through the pre-test data entry you define, then when ready, the software will perform pre-cracking (if required) and finally onto the main fracture test.

Run a Test

Pre-configured material properties and pre-cracking targets reduce user input and increase throughput.

Post-test Analysis

The software guides operators through data input, graph plotting and results calculation.

Report Generation

The report and export function within Bluehill Fracture completely automates the process of generating a summary report.

SAFER

Control user access and check results

Validity checks confirm your tests are within predefined parameters whilst the security settings allow advanced users to protect areas of the method containing critical settings.

Analysis

The report and export function within Bluehill Fracture completely automates the process of generating a summary report. This reduces complexity, time and errors by avoiding additional data export and manipulation at the post test reporting stage.

Whether you need a summary in text output format or a fully customized PDF report in your organization’s format, Bluehill Fracture has the features to achieve this at the click of mouse button.

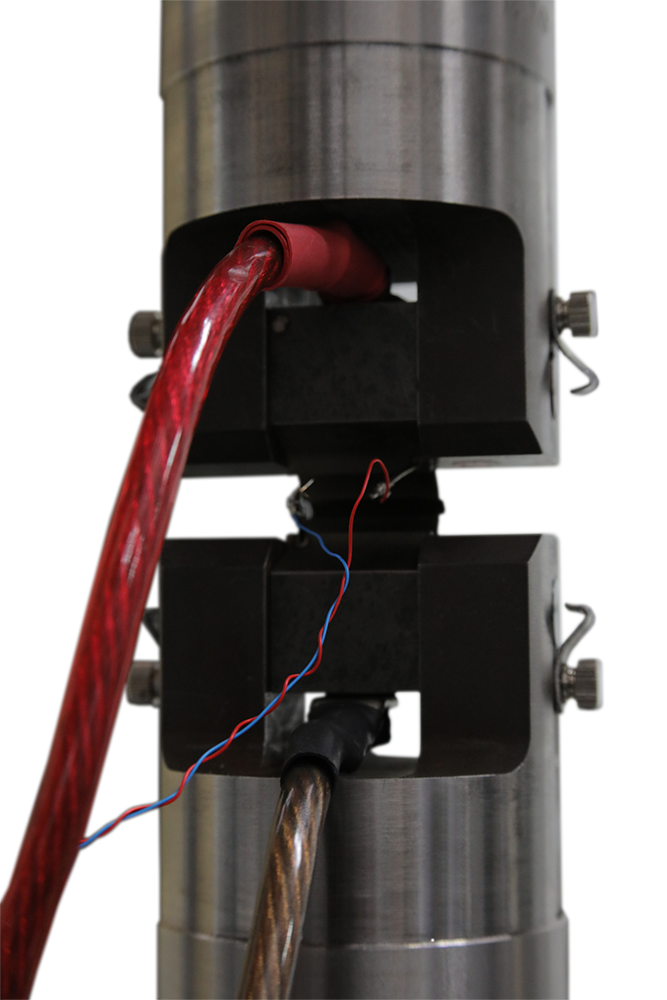

Test control and method set up are similar to mechanical compliance-based methods and raw data is stored in the same way. Signal noise depends greatly on the preamplification and conditioning of the DCPD system, so an additional averaging feature is available to stabilize readings during crack growth.

For fracture toughness determination, corrected displacement is calculated from user-specified frame compliance coefficients stored within the method, so that correct analyses can be used for different load strings. Manual and automated methods of V0 determination are provided, with a configurable interval for generation of J-da plot.

SUPPORTING DCPD MEASUREMENTS

Integration

Various functions are available to support integration with laboratory data management systems (e.g. LIMS), such as the option to import automatically generated inputs of specimen geometry and material properties.

Supported Features

Bluehill Fracture modules support all common test standards (ASTM, ISO and BS) for crack propagation, ductile and brittle fracture, crack length measurements and specimen geometries. Users can test to predefined standards (e.g. ASTM E647, ASTM E399, ASTM E1820, ISO 12135).

For the latest Bluehill Fracture standard compatibility:

Compatibility

Bluehill Fracture is available with new ElectroPuls® and Servohydraulic systems, as well as any existing dynamic testing system with an 8800 or 8800MT controller running Windows 7 or 10.

| 供应型号 | |

| 载荷容量选型 | 目录编号 |

| 50 N | 2712-051 |

| 250 N | 2712-052 |

|

|||||

|

最大钳面开口 |

|

|||

| 100 N | 35 mm | 2710-111 | |||

| 500 N | 35 mm | 2710-112 | |||

| 1 kN | 36 mm | 2710-113 | |||

| 2 kN | 36 mm | 2710-114 | |||

| 5 kN | 46 mm | 2710-115 | |||

| 10 kN | 46 mm | 2710-116 | |||

| 规格 | ||

| 载荷容量选型 | 最大试样厚度 | 目录编号 |

| 10 N | 0.8 mm | 2712-101 |

| 规格 | ||

| 载荷容量选型 | 目录编号 | |

| 10 N | 2860-001 | |