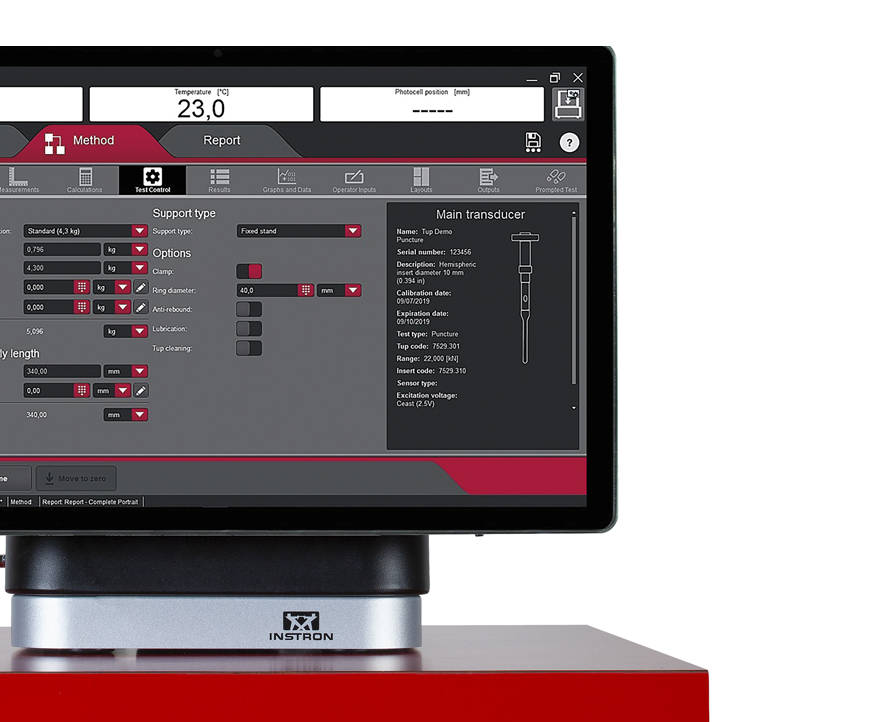

Testing Software

Bluehill® Central Quiz

Bluehill Central could be a great way to optimize your lab operations! Bluehill Central may not be useful to optimize your lab today. If you wish to submit product requests, please enter below for the Bluehill team to consider.

Q1 : Would the digitization of material test processes and networking of machines benefit your lab? Yes

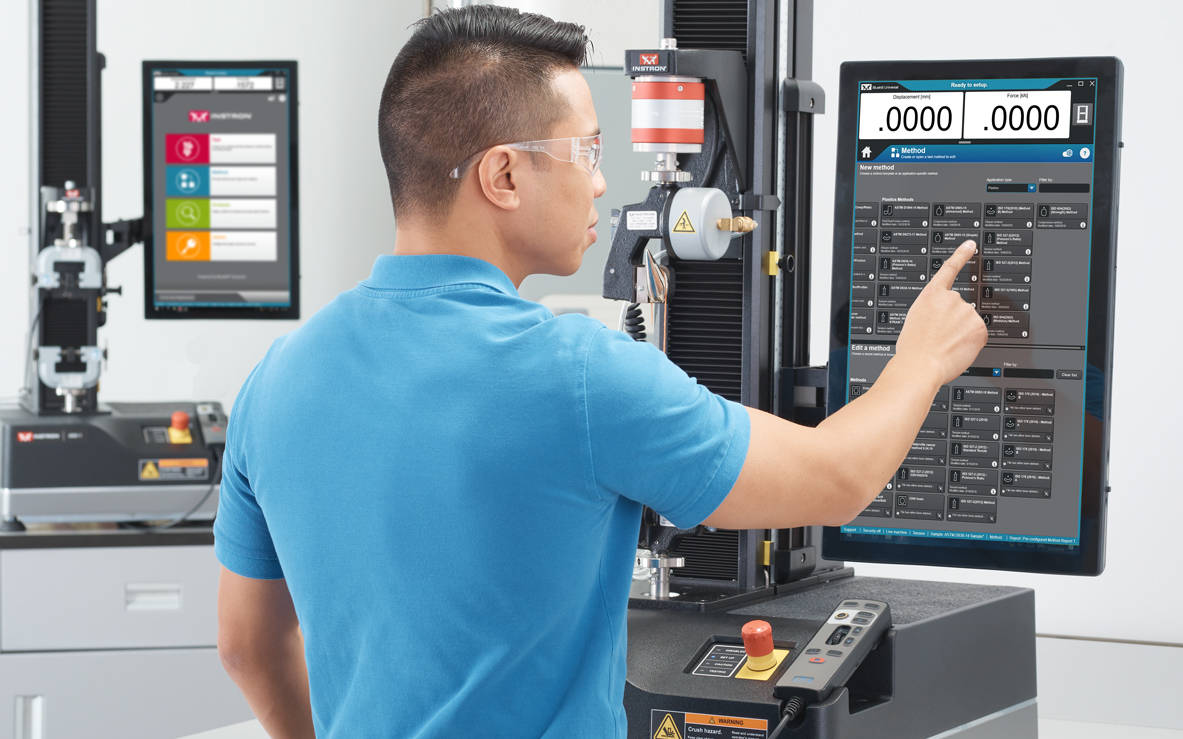

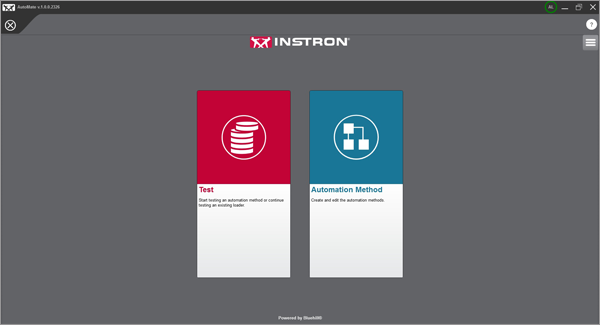

Solution: Networked lab management software tool for Instrons

Bluehill Central is built to enable the digitization of processes and networking of your Instron machines. Improve efficiency, lower risk, and position your lab to compete into the future by connecting your Instrons to Bluehill Central. All data is secured within your corporate domain.

Q2 : Is it challenging to share test method files across multiple Instrons? Yes

Solution: Centralized file storage

Bluehill Central’s Lab Management module allows you to store test method, report template, and result files to a centralized database that all your Instron systems can access, creating one source of truth for testing procedures and reports. Multiple teams can be configured to organize Bluehill files for different groups of users.

Q3 : Have you encountered problems caused by an operator using the wrong test method? Yes

Solution: Centralized file storage with team management

Bluehill Central’s Lab Management module allows you to store test method, report template, and result files to a centralized database that all your Instron systems can access, creating one source of truth for testing procedures and reports. Multiple teams can be configured to organize Bluehill files for different groups of users. Files can be “locked” by configuring read and write access for specified users.

Q4 : Have you ever lost data or a method because the Bluehill file was accidentally overwritten? Yes

Solution: Automatically archived revisions

Bluehill Central’s Lab Management module allows you to store test method, report template, and result files to a centralized database that all your Instron systems can access, creating one source of truth for testing procedures and reports. All file revisions are stored and can be recovered. Files can be “locked” by configuring read and write access for specified users.

Q5 : Do you have trouble accessing test data when away from the lab? Yes

Solution: Centralized file storage to access from anywhere

Bluehill Central’s Lab Management module allows you to store test method, report template, and result files to a centralized database that all your Instron systems can access, creating one source of truth for testing procedures and reports. As the database is hosted on your network, you can access testing files from anywhere to review data. Multiple teams can be configured to organize Bluehill files for different groups of users.

Q6 : Do you require review or approval of new or modified methods before operators run tests? Yes

Solution: Revision control workflows

With Bluehill Central’s Traceability module, you can utilize electronic sign-offs to set up a revision control process. Up to 3 signatures can be required for methods, report templates, test samples, and PDF reports. Signatures are stored digitally in the associated file, but also in the centralized audit trail. While a file is pending review, the previously approved method can continue to be used. Reviews can be performed locally on the system or remotely from a Bluehill Central viewer.

Q7 : Do you require an audit trail tracking changes and activities of your Instron testing? Yes

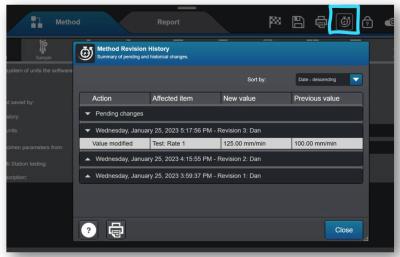

Solution: File revision history and electronic audit trail

With Bluehill Central’s Traceability module, you can see a detailed change log of all edits to a particular file and access an audit trail of all system activity. The audit trail is displayed chronologically and can be filtered to find activities associated with a specific system, time period, file, etc. And everything is viewable remotely!

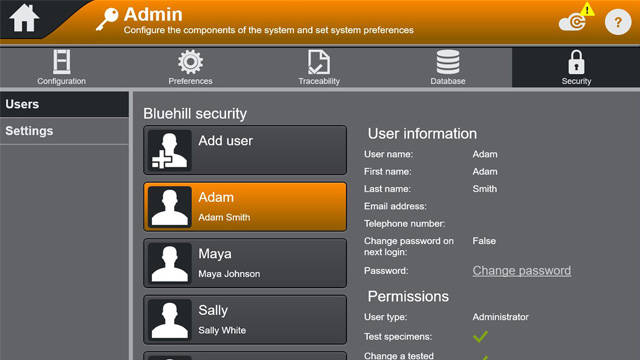

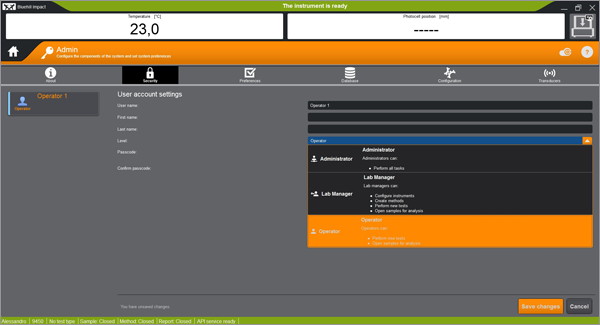

Q8 : When managing user accounts and security permissions, is it annoying to configure accounts locally at each Instron instead of remotely? Yes

Solution: Centralized user management and Teams

With Bluehill Central, you can create and edit users/permissions for all systems from one location. You can organize users into groups, or Teams, ensuring the correct people have access to the correct files.

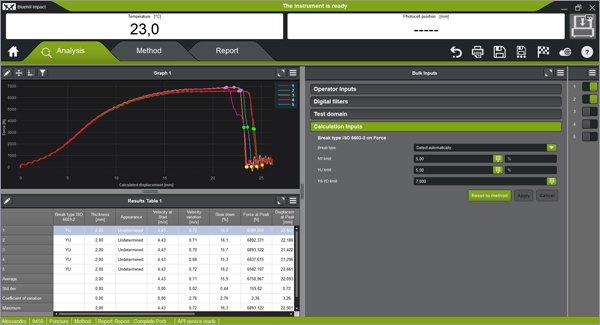

Q9 : Do you find it difficult to collect and analyze Instron test data from multiple batches? Yes

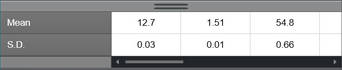

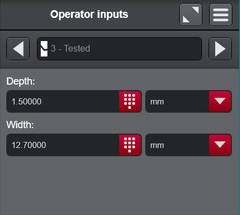

Solution: Centralized SQL database and multi-sample analysis

Bluehill Central’s TrendTracker module automatically stores testing results in a searchable SQL database. You can create and save custom searches in the TrendTracker module. Searches can be organized by testing date, batch number, part number, etc., allowing you to analyze your test data in numerous ways.

Contact Our Sales Department.

To connect with the Instron Sales team, please complete the form below. We typically respond to online inquiries within 1–2 business days. Looking for a quicker reply? Visit our locations page to find the nearest office and connect with us directly.